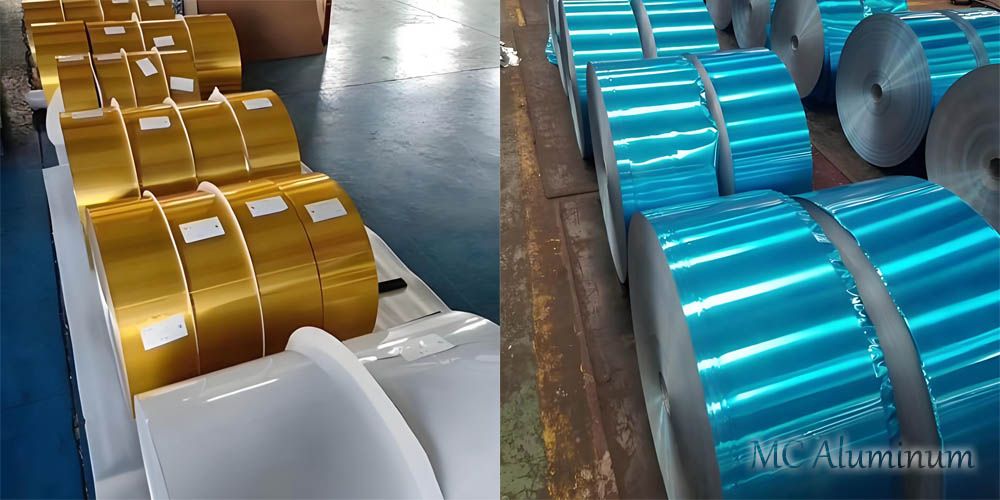

3102 / 8011 H22 Air-Conditioner Aluminum Foil Jumbo Rolls

Air-conditioner aluminum foil is a specialized material used to manufacture heat exchanger fins. These densely packed ultra-thin fins act as bridges for heat transfer, directly affecting the cooling/heating efficiency and service life of the air conditioner. According to industry data, hydrophilic aluminum foil now accounts for over 80% of total AC aluminum foil usage, becoming the mainstream choice.

Compared to ordinary aluminum foil, specially treated hydrophilic aluminum foil can increase cooling efficiency by approximately 5%, making it a key material for energy-efficient, compact modern air conditioners.

Common Alloys for Hydrophilic AC Aluminum Foil

3102 Aluminum Alloy Foil

3102 aluminum foil belongs to the Al-Mn alloy series. The addition of manganese significantly enhances solid solution strengthening, giving the foil higher strength and excellent deep-drawing performance even in the annealed (O) condition.

This material is widely used in high-efficiency heat exchangers requiring high strength and formability, such as the indoor and outdoor units of variable-frequency air conditioners.

8011 Aluminum Alloy Foil

8011 aluminum foil is an Al-Fe-Si alloy. Compared to 3102, it offers higher strength and hardness, allowing fins to better resist deformation or impact during manufacturing, transport, and installation.

8011 aluminum also has slightly better corrosion resistance than 3102, making it ideal for commercial air conditioners, automotive heat exchangers, and cost-sensitive residential AC units.

H22 Temper

The H22 temper represents a semi-hard temper state, balancing the requirements of strength and formability.

The H22 temper (partially annealed after work hardening) provides ideal cupping value and elongation through precise annealing process control, ensuring zero cracking and high flanging height on high-speed presses.

Technical Specifications

| Alloy | 3102 / 8011 |

| Temper | H22 (most common), H24, H26 |

| Thickness | 0.08 mm - 0.20 mm (±3% tolerance) |

| Width | 200 mm - 1300 mm (custom slitting available) |

| Coil Core ID | 75 mm / 150 mm / 200 mm / 300 mm (steel/aluminum/paper cores) |

| Max Coil OD | Up to 1600 mm |

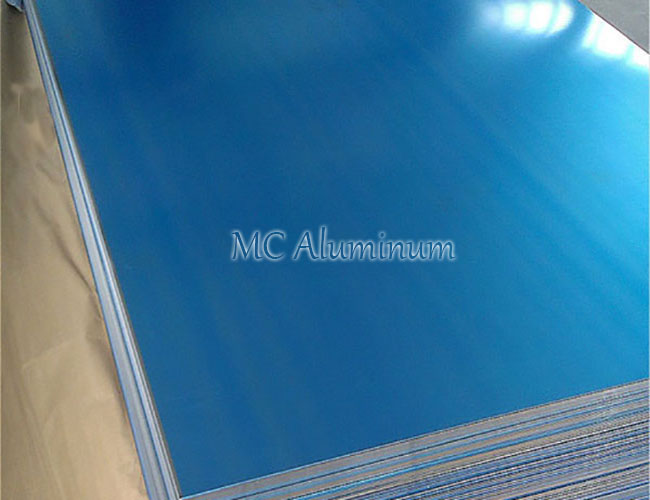

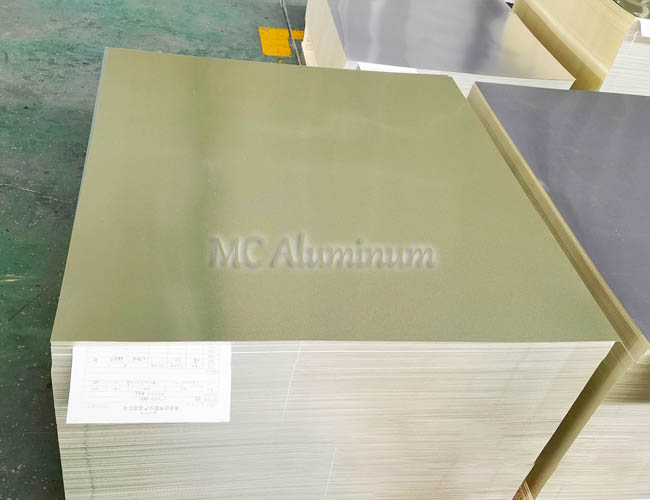

| Color Options | Blue, gold, white, green, black, customizable |

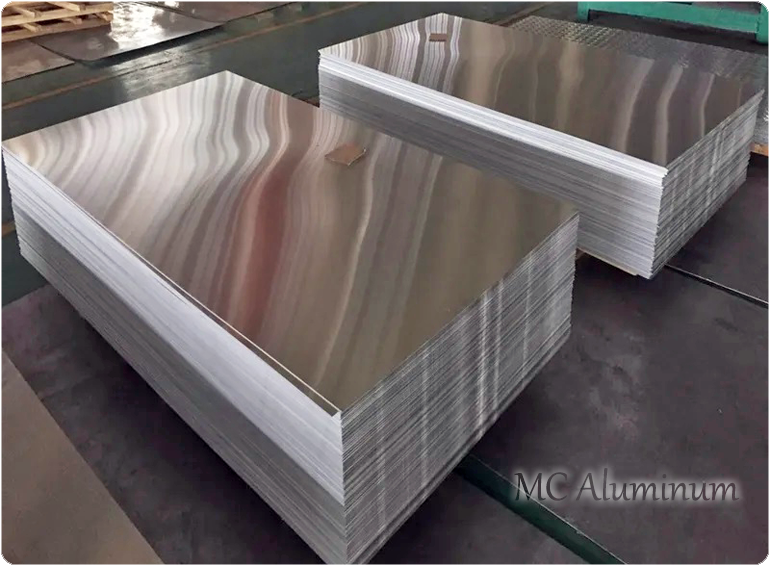

| Surface Treatment | Hydrophilic coating, hydrophobic coating, or uncoated |

| Surface Quality | No oil spots, no pinholes, no coating peeling, no scratches, no black lines |

| Tensile Strength | 120 - 165 MPa |

| Elongation | ≥ 2.0% (based on 0.1 mm thickness) |

| Cupping Value | ≥ 6.0 mm |

| MOQ | 1 - 3 tons |

Performance Advantages of 3102 / 8011 Hydrophilic Aluminum Foil

1. Superior Deep Drawing and Formability: Designed specifically for high-speed precision stamping. The H22 temper provides an optimal balance of toughness, ensuring no cracking or springback during complex punching, flanging, and ribbing processes, guaranteeing a perfect fin shape.

2. High Thermal Conductivity: Utilizing a high-purity base material with extremely low thermal resistance. It rapidly exchanges hot and cold energy, significantly improving the energy efficiency ratio (EER) of the air conditioning unit and helping the end product achieve the highest energy efficiency standard.

3. Enhanced Corrosion Resistance: The aluminum surface has a built-in protective oxide layer. In particular, the 3102 alloy (containing manganese) exhibits stronger corrosion resistance in salt spray and humid environments, significantly extending the service life of the outdoor unit and condenser.

4. Extremely Clean Surface: A rigorous degreasing process ensures a surface free of oil spots and residue. With high surface tension (dyne value), it ensures unobstructed airflow and is an ideal substrate for applying hydrophilic coatings.

5. Lightweight and High Strength: Supports thinner thicknesses while maintaining structural rigidity. Compared to copper and ordinary aluminum alloys, it effectively reduces the weight of the heat exchanger, achieving dual savings in material and transportation costs.

Surface Coating Technologies

Hydrophilic Coating

Hydrophilic aluminum foil is the most common coated aluminum foil used in air conditioners. Applying a hydrophilic coating to the aluminum foil surface allows water droplets to spread out on the fin surface, forming a water film instead of condensing into droplets.

This property effectively prevents water droplets from clogging airflow channels, improving heat exchange efficiency. Simultaneously, the coating isolates the aluminum material from corrosive substances in the condensate, extending the fin's lifespan.

Even under low-temperature operating conditions, the hydrophilic coating helps reduce frost formation, maintaining efficient system operation.

Hydrophobic Coating

Hydrophobic aluminum foil is primarily used in environments with high corrosion resistance requirements, such as coastal areas or special industrial environments. Its surface is coated with a hydrophobic (waterproof) or more acid and alkali resistant coating, providing excellent corrosion resistance and self-cleaning properties.

Strict Quality Control

Online Pinhole Detection: Ensures no perforations for airtightness

Degreasing Control: Bending and straightening cleaning process ensures proper Dyne value for coating adhesion or wetting

Mechanical Testing: Tensile and cupping tests performed for each batch with MTC certification

Surface Quality:

(1)Flat coil surface ensures smooth uncoiling without edge damage

(2)Clean surface free of oil spots or scratches, suitable as bare foil or as a base for hydrophilic coatings

Contact Us