- sales@alummc.com

- Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

The color painted aluminum strip is an aluminum deep-processed product formed by slitting of color coated aluminum coils.Classified by alloy model, our color-coated aluminum belts are divided into three series: 1000 series, 3000 series and 8000 series:

(1) 1100 color-coated aluminum coils are pure aluminum with excellent forming properties, 1100 H14 aluminum-coated coils are usually used to make rain gutters, and 1100 H12 O-coated aluminum coils are usually used to make fins, heat exchanger fins piece.

(2) 3003 color-coated aluminum coil is an important alloy in my country. The price is cheaper than 3105, and it is basically the same as 1100, 1060, 1070 and other alloys, but has medium strength, good atmospheric corrosion resistance, very good weldability and good cooling Formability. It has better mechanical properties than 1000 series alloys, especially at high temperatures. Therefore, 3003 aluminized coils are widely used in the construction industry, such as roofing and siding, ceilings, corrugated boards, and have good heating and cooling insulation.

(3) 3105 color-coated aluminum coil is an aluminum alloy with a purity of 98%. The addition amount in terms of strength is very small. Because it contains manganese, its corrosion resistance is very good, and its strength is greater than that of 1000 series alloys. , but its price is almost the same as the 1000 series alloy, so it is widely used in the manufacture of roofing.

(4) 8011 color-coated aluminum coil is the most popular commercial alloy in the packaging industry.

| Alloy | 1100,3003,3105,8011 |

| Temper | H16, H26, H24, H22, H18 |

| Al Thickness | 0.04~1.20mm |

| Coating Thickness | double coating-25 micron, single coating-18 micron, primer-5 micron |

| Coating | PE/HDPE/PVDF/FEVE/PU |

| Width | 20-1700mm |

| Surface treatment | anti-scratch, high glossy, matte |

| Coating technique | 1-6 coated |

| Color | wooden grain, marble stone, plain color,3D, HD, metallic, patterned, etc. |

| Coating adhesive | no lower than first grade |

| Impact resistance | no cracking and peeling(50kg/cm, ASTMD-2794:1993) |

| Coating Density | 0.890 g/cm3 |

1.Light weight, high strength, extreme rigidity, superior impact resistance

2.Excellent surface flatness and smoothness

3.Heat insulation, sound insulation, fire-resistance

4.Acid-resistance, alkali-resistance, good weatherproofing and non-resonance

5.Various uniform colors ,can be easily processed and fabricated, quickly installed

6.Elegant and magnificent, good flexibility fits various designs

7.Easily maintenance, simply cleaning

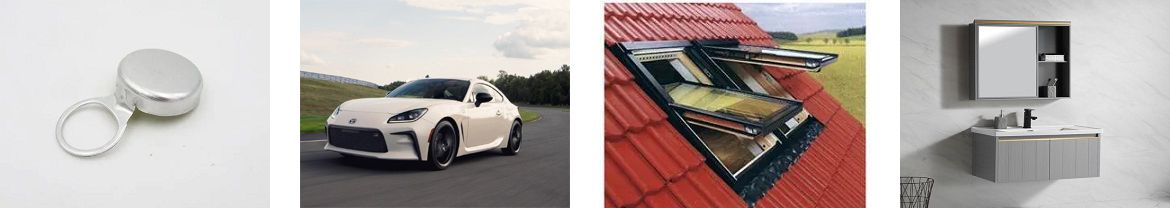

Color-coated aluminum strips are widely used for walls, facades, roofs and canopies, tunnels, column caps or renovations. Indoor applications: walls (laminate), ceilings, bathrooms, kitchens and balconies. Automobile industry, washing machine cylinder; tank body; can cover pull ring; marine equipment materials and parts; instrumentation materials; building materials and accessories; sound insulation walls; maintenance boxes, capacitor boxes, bearings, TV cabinets, magnetic disks, motor racks, Container packaging, nameplates and other motor assemblies.

Packing Details : Standard export package.

Wooden plate, covering with craft paper and film, Eye to Sky or wall to Sky packing.

Wooden cases