3102 Aluminum Alloy Fins for Air Conditioners

In modern air conditioner manufacturing, the performance of the heat exchanger directly determines the overall efficiency, noise level, service life, and operational stability of the entire unit.

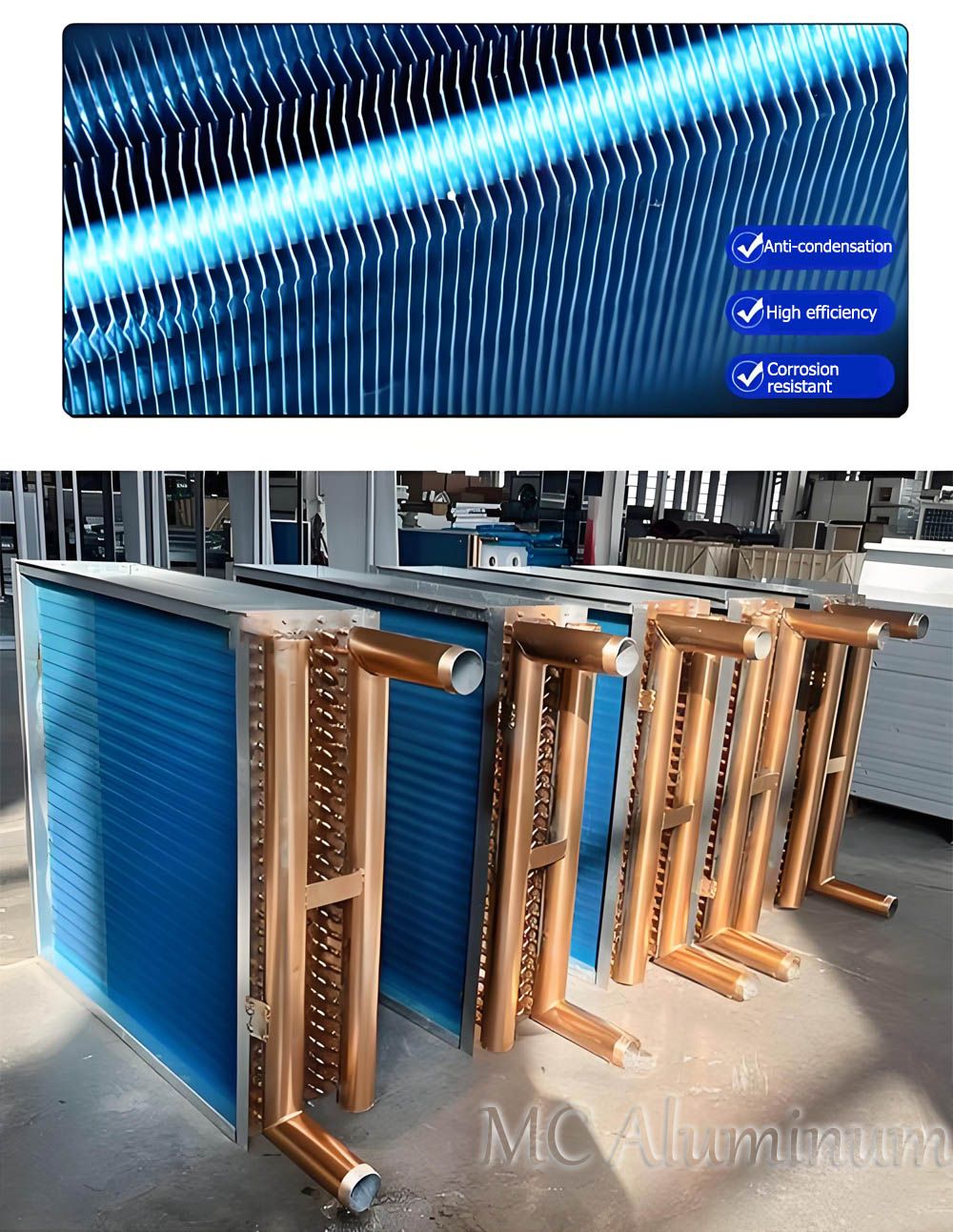

Among the many components of a heat exchanger, the fin plays a vital role - it is responsible for heat transfer, airflow distribution, and condensate drainage.

Among various fin materials, 3102 aluminum foil stands out as one of the most widely used materials for evaporators and condensers, offering higher thermal efficiency, lighter weight, and superior corrosion resistance.

What Is 3102 Aluminum Foil?

3102 aluminum alloy belongs to the Al-Mn (aluminum-manganese) series of wrought alloys. It is a non-heat-treatable alloy strengthened mainly through cold working.

Its chemical composition contains about 99.2% aluminum, with small additions of manganese (Mn) and copper (Cu) to enhance mechanical strength and corrosion resistance.

Compared to commonly used 1050 and 1060 pure aluminum, 3102 offers better strength and durability while maintaining excellent thermal conductivity and workability.

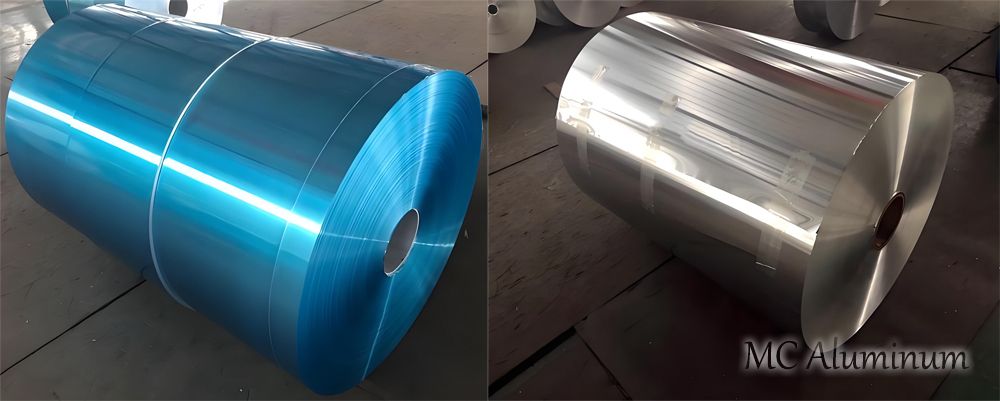

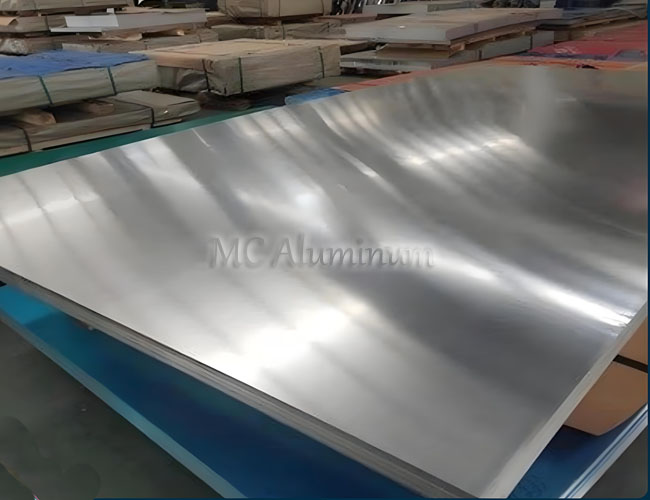

3102 aluminum foil for fins usually refers to ultra-thin aluminum foil with a thickness between 0.08 mm and 0.25 mm. It is available in temper conditions such as O, H22, H24, and H26. After precision stamping, it becomes the heat-dissipating fins used in heat exchangers.

In air conditioner systems - both indoor and outdoor units - 3102 foil is used to manufacture fins for evaporators and condensers. The foil is punched, flanged, expanded, degreased, and assembled to form complete heat exchangers.

Technical Specifications of 3102 Air Conditioner Aluminum Foil

Technical Specifications of 3102 Air Conditioner Aluminum Foil

| Alloy | 3102 |

| Temper | O, H22, H24, H26 |

| Thickness | 0.08mm - 0.25mm |

| Width | 20mm - 1200mm |

| Length | Customized as required (available in coil or sheet form) |

| Surface Treatment | Bright surface, coated, hydrophilic coating, anti-corrosion coating |

| Inner Diameter | 75, 150, 300, 400 mm |

| Outer Diameter | Customizable |

| Thermal Conductivity | 160 - 200 W/m·K |

| Tensile Strength | 120 - 180 MPa (H16 condition) |

| Elongation | ≥20% |

| Applications | Heat exchanger coils, condenser coils, evaporator coils, air coolers |

| MOQ | 1-3 tons |

Key Properties of 3102 Aluminum Alloy Fin Foil

1. High Thermal Conductivity

3102 alloy has a thermal conductivity of 160-200 W/m·K, allowing for rapid and efficient heat transfer.

This property makes it an ideal material for air conditioning condensers, evaporators, and heat exchangers, enhancing system efficiency.

2. Excellent Formability

3102 aluminum foil can be easily stamped, stretched, bent, or rolled, enabling the production of fins as thin as 0.08 mm without tearing or cracking.

It is perfectly suited for various heat exchanger designs requiring complex fin geometries.

3. Superior Corrosion Resistance

An aluminum oxide film naturally forms on the surface of aluminum, providing inherent corrosion resistance.

The addition of manganese (Mn) further improves oxidation and corrosion resistance, allowing 3102 foil to perform reliably in humid, salty, or condensing environments, thus extending the lifespan of heat exchangers.

4. Lightweight and High Strength

With a density of 2.7 g/cm³, 3102 aluminum is only one-third the weight of steel, reducing the total weight of air conditioning units and improving energy efficiency while maintaining sufficient structural strength.

5. Excellent Weldability and Brazability

3102 can be brazed or high-frequency welded with other aluminum alloys (e.g., 3003, 6061).

It offers stable welding performance and strong joints, ensuring the tightness and reliability of the assembled heat exchanger.

Applications of 3102 Aluminum Fins in Air Conditioning Systems

1. Household Air Conditioners

Used in evaporator and condenser fins, 3102 aluminum ensures smooth airflow, efficient cooling, and reduced energy consumption and noise levels.

2. Commercial HVAC Systems

In large-scale cooling and heating systems, 3102's anti-corrosion properties ensure reliable operation under high humidity and salt-spray conditions, common in marine or coastal environments.

3. Automotive Air Conditioning

Owing to its lightweight and vibration-resistant properties, 3102 aluminum foil is widely used in car condenser and evaporator fins, contributing to better vehicle fuel efficiency.

4. Refrigeration and Heat Pump Systems

3102 aluminum fins are also employed in refrigeration units, freezers, heat pump dryers, and air-source heat pumps, enhancing overall heat transfer performance and system reliability.

Comparison with Other Fin Materials

| Material | Thermal Conductivity | Corrosion Resistance | Formability | Cost | Recommended Application |

| 1050 Pure Aluminum | Excellent | Average | Excellent | Low | General heat exchangers |

| 3102 Aluminum Alloy | Very Good | Excellent | Excellent | Moderate | High-efficiency HVAC systems |

| 3003 Aluminum Alloy | Good | Excellent | Good | Moderate | Standard cooling applications |

| Copper Fins | Superior | Excellent | Poor | High | High-end cooling systems |

Contact Us