3102 O-Temper Aluminum Foil for Air Conditioning Applications

3102 aluminum alloy is an Al–Mn series alloy whose properties fall between those of industrial pure aluminum and hard aluminum alloys. The addition of manganese improves its strength while maintaining excellent formability.

Compared with 3003 aluminum alloy, 3102 offers better corrosion resistance and processing performance. In the fully annealed O-temper, 3102 aluminum foil is soft and highly workable, making it ideal for composite packaging, deep-drawn containers, electronic heat dissipation parts, and applications requiring complex forming.

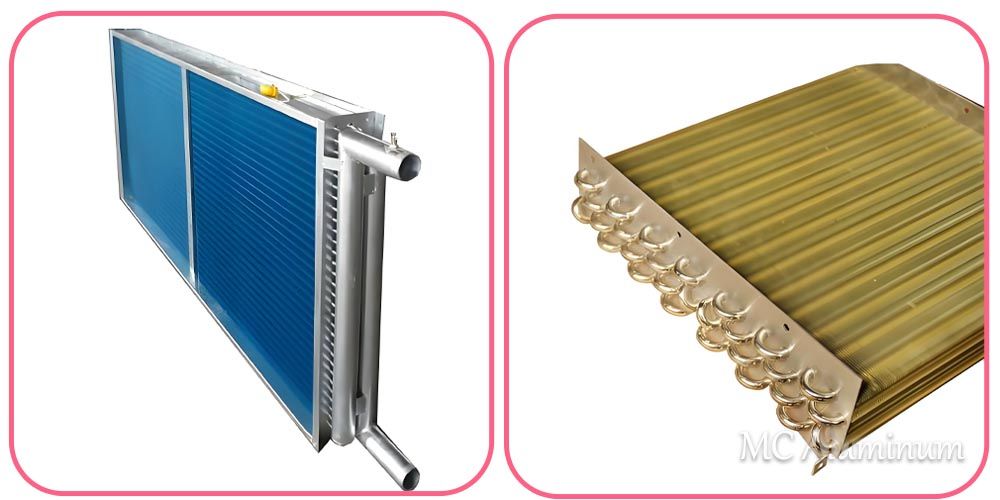

Among all uses, air conditioner fin stock is the most important application for 3102 O aluminum foil. It is the specialized material used for manufacturing the heat exchanger fins in air conditioner units. Both indoor and outdoor units require a large number of fins to form the heat exchanger, and 3102-O aluminum foil is the ideal choice for producing these components.

MC Aluminum offers a thickness range of 0.09-0.11 mm, widths of 100-1200 mm, and customizable lengths.

3102 O aluminum foil is also the primary base material for producing hydrophilic aluminum foil. Hydrophilic foil is coated with a hydrophilic layer to enhance corrosion resistance, prevent oxidation, improve heat exchange efficiency, and extend the service life of HVAC equipment.

Performance Advantages of 3102 Aluminum Foil

1. Excellent Corrosion Resistance

3102 alloy performs exceptionally well in humid, salty, and refrigerant-rich environments. This is crucial for components in heat exchangers, which are frequently exposed to condensate water and chemical refrigerants such as Freon. High corrosion resistance ensures long-term durability and extends equipment life.

2. Strength with Good Weldability

While maintaining low weight, 3102 provides suitable mechanical strength. Its stable chemical composition allows reliable brazing or welding with copper or aluminum tubes, ensuring highly airtight connections during heat-exchanger assembly.

3. Superior Formability

The O-temper state provides maximum ductility, allowing the foil to be formed into small radii and complex geometries without cracking or stress fracture.

4. Electrical Conductivity

The conductivity of 3102 foil falls between pure aluminum and harder aluminum alloys. This makes it useful for low-voltage electrical components, heat-dissipation parts, and shielding materials.

5. High-Quality Surface Finish

The surface of 3102 foil is smooth, bright, and free from black spots, scratches, oxidation marks, oil stains, or corrosion traces. The coils are neatly wound with stable tension, meeting the requirements of high-end coating, laminating, and printing processes.

Core Application Fields of 3102 Aluminum Foil

1. Household and Commercial Air Conditioning Systems

Used primarily for manufacturing evaporator and condenser fins. The fins enable efficient heat transfer, and 3102’s corrosion resistance ensures reliable long-term performance in humid environments.

2. Automotive Heat Exchangers

Applied in automotive radiators, intercoolers, and oil coolers. The lightweight nature of 3102 helps reduce vehicle weight and improve fuel efficiency.

3. Industrial Refrigeration and HVAC Systems

Suitable for heat-exchange components in industrial refrigeration equipment, ventilation systems, and large-scale HVAC units.

Quality Control of 3102 Aluminum Foil

Thickness Tolerance and Uniformity

Because the foil is extremely thin (typically 0.09-0.2 mm), strict thickness tolerance is essential to ensure heat-exchange efficiency and dimensional accuracy in assembly.

Pinhole Rate

Pinhole count is a critical indicator of foil quality. 3102 aluminum foil must maintain an extremely low pinhole rate to guarantee airtightness and prevent refrigerant leakage.

Surface Cleanliness

The foil surface must be free of oil, dust, and oxides to ensure optimal adhesion during brazing or hydrophilic coating processes.

Contact Us