5052 H32 Aluminum Sheet Marine Applications

Marine fabrication rarely fails because of a single major mistake. More often, performance issues develop from a combination of avoidable material mismatches: accelerated pitting at crevices, cosmetic staining after months in coastal air, distortion during forming, cracking at bent corners, or costly rework when a chosen alloy cannot be welded or finished as expected. Overseas buyers also face a practical challenge: different mills may quote similar alloys and tempers, yet deliver very different forming consistency and surface quality, which then affects production yield.

5052 H32 aluminum sheet is widely selected for marine applications because it targets these pain points directly. As a 5xxx series Al-Mg alloy, 5052 offers strong resistance to seawater and salt-laden atmospheres, good weldability, and reliable forming behavior. The H32 temper, in particular, balances strength and ductility for boat structures and marine components that must be formed, fastened, and welded without sacrificing corrosion performance.

Why 5052 H32 Is Considered a Practical Marine-Grade Choice

5052 is often used when the environment is clearly marine, but the design also requires fabrication flexibility. It sits in a useful middle ground: more corrosion resistant than many general-purpose aluminum alloys, while typically easier to form than higher-strength marine grades in more heavily strain-hardened tempers.

Key material characteristics

Corrosion resistance in marine exposure: 5052 is known for strong resistance to salt spray and seawater environments, particularly in atmospheric exposure and splash zones. Like other 5xxx alloys, it benefits from magnesium-driven corrosion performance. Proper design still matters: stagnant seawater, crevices, and dissimilar-metal contact can drive localized corrosion if not managed.

Formability and bend performance: Compared with higher-strength tempers, 5052 H32 generally supports tighter bending radii and more predictable forming, which helps reduce cracking at corners or around cutouts.

Weldability: 5052 is commonly welded in marine fabrication. Weld procedure and filler selection depend on the joint design and service environment, but the base alloy is widely regarded as weld-friendly.

Fatigue and vibration considerations: Small vessels and shipboard components see cyclic loading and vibration. While aluminum is not immune to fatigue, 5052 is frequently used for components where moderate strength and good fabrication quality are prioritized.

Alloy advantages versus other common marine choices

Marine buyers often compare 5052 with 5083, 5086, 5754, and 6061:

5052 vs 5083/5086: 5083 and 5086 are popular for heavier-duty shipbuilding and high-strength plate applications. 5052 is often chosen when forming and general fabrication are critical, and when extreme strength is not the primary driver.

5052 vs 5754: 5754 is also a corrosion-resistant Al-Mg alloy used in marine and transport. Selection may come down to local availability, thickness range, and forming requirements.

5052 vs 6061: 6061 is widely used for structural parts and extrusions, but in sheet form it is typically selected for different reasons (heat-treatable strength and machining), and it can be less forgiving in tight forming compared with 5052.

For buyers comparing options within a supplier catalog, 5052 Aluminum Sheet is often positioned as a marine-capable sheet product for formed and welded components, while heavier ship structures may shift toward 5083 Aluminum sheet depending on design loads.

Understanding H32 and Other Common Tempers in Marine Sheet

Temper selection is often the difference between a part that forms cleanly and one that cracks, or a panel that stays flat and one that shows excessive distortion after fabrication. For 5052 and other strain-hardened 5xxx alloys, H tempers indicate cold work, sometimes followed by stabilization.

What H32 means

H indicates strain-hardened (work-hardened) material.

H3 indicates strain-hardened and stabilized. Stabilization is used to reduce changes in mechanical properties over time that can occur in certain alloys after cold working.

H32 indicates a specific level of strain hardening, generally considered a moderate-strength temper.

In marine applications, 5052 H32 is widely used because it provides a balance of strength for panels and brackets while retaining enough ductility for bending and forming operations.

Other 5052 tempers you may encounter

H34

A higher level of work hardening than H32. It typically offers higher strength but reduced ductility. It can be suitable when forming is limited (larger bend radii, less complex shapes) and when increased stiffness or dent resistance is valued.

O temper (annealed)

The softest temper, offering maximum ductility and the easiest forming. It is useful for deep drawing or complex forming where cracking risk is high. However, the lower strength may require thicker gauges or additional stiffening in marine assemblies.

H112

A common temper designation for products that have received some work hardening from processing but without meeting the requirements of a specific H2x or H3x temper. It is often seen in plate products. Suitability depends on the forming and strength requirements of the part.

Practical temper selection scenarios (examples)

Formed covers, housings, or curved panels: 5052 H32 is frequently chosen to reduce forming failures while maintaining useful stiffness.

Flat panels requiring higher dent resistance: 5052 H34 may be considered when forming is minimal.

Deep-formed parts or complex bends: 5052 O temper can improve yield in forming-intensive production, followed by design measures to compensate for lower strength.

Processing Performance: What Marine Fabricators Value

Overseas buyers often evaluate not only the alloy but also how the sheet behaves on the shop floor. 5052 H32 is frequently specified because it is predictable across key fabrication steps.

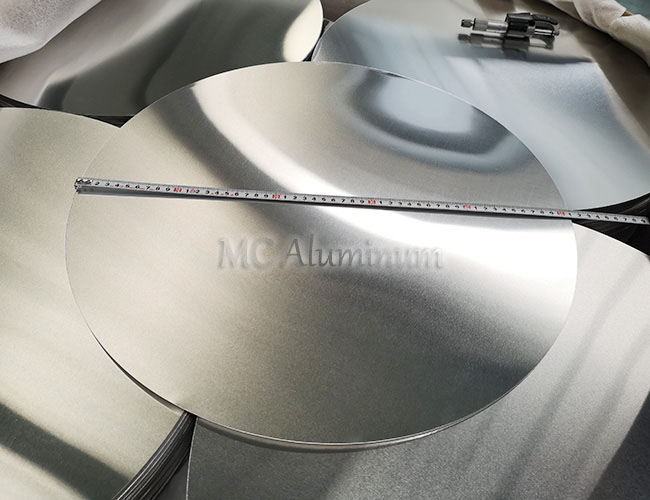

Cutting and machining

5052 can be cut using common methods (shearing, sawing, laser cutting), though parameters and edge quality will vary by thickness and equipment. For marine parts, edge quality matters because rough edges and burrs can become initiation points for corrosion or cracking under vibration.

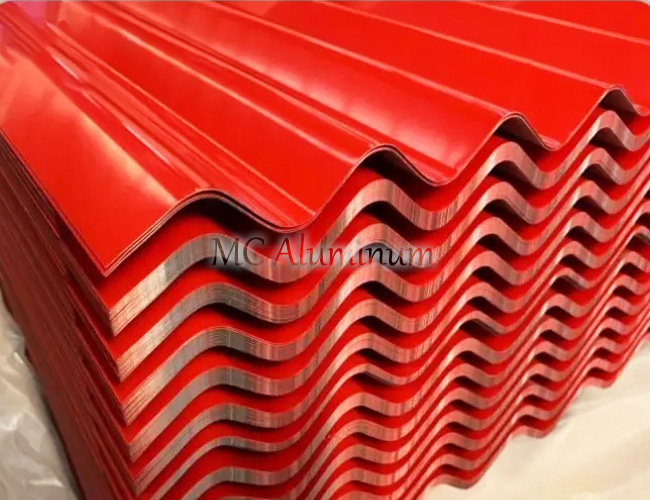

Forming and bending

5052 H32 generally supports reliable press-brake forming for brackets, stiffeners, and enclosures. Buyers should still validate bend radii and tooling based on thickness and grain direction. Tight bends across the rolling direction are typically more demanding than bends with the grain.

Welding performance

5052 is widely used in welded marine assemblies. Control of heat input, joint design, and surface cleanliness are critical in marine service. If a design relies heavily on welded seams in highly stressed areas, buyers may also review alternatives like 5083/5086 depending on structural requirements.

Surface finishing and protection

In marine environments, finishes are often selected to reduce staining, improve appearance, or provide an additional barrier:

Anodizing can be used for many components, but the appearance and color uniformity on Al-Mg alloys may differ from other series.

Marine coatings and paint systems are commonly used on hulls, superstructures, and decks. Proper surface preparation is essential.

Isolation from dissimilar metals is important. Contact with stainless steel fasteners or copper-containing alloys can accelerate galvanic corrosion in the presence of seawater unless isolated.

Typical Marine Applications of 5052 H32 Aluminum Sheet

5052 H32 is typically selected for fabricated marine components where corrosion resistance and formability are essential, and where sheet thickness (rather than heavy plate) is appropriate.

Common boat and ship components

Interior and exterior panels: bulkhead panels, access panels, equipment covers

Cabin and superstructure parts: non-critical structural skins, consoles, instrument housings

Deck hardware and fabricated brackets: mounting plates, supports, shields, battery trays

Tank-related components: in some designs, Al-Mg alloys are used for tank fabrications, but suitability depends on the stored medium and regulatory requirements

Ventilation and ducting: formed ducts and louvers in corrosive atmospheres

Gangways, steps, and protective trims: where light weight and corrosion resistance are needed

5052 is also used in coastal infrastructure and offshore-adjacent applications where salt-laden air is constant, such as covers, housings, and enclosures for marine equipment.

Standards and Documentation Overseas Buyers Commonly Request

Marine buyers often need traceability and internationally recognized standards for chemical composition and mechanical properties. The following standards are commonly referenced for aluminum sheet products. Confirm applicability to your project requirements and region.

| Item | Common reference | Notes for buyers |

|---|---|---|

| Aluminum alloy and temper designation | ASTM B209 | Frequently used for aluminum and aluminum-alloy sheet and plate in many export transactions. |

| Wrought aluminum alloy designation system | EN 573 (series) | Commonly used in Europe for chemical composition conventions. |

| Mechanical properties by product form | EN 485 (series) | Often referenced in Europe for sheet, strip, and plate properties. |

| Quality management system certification | ISO 9001 | Many mills and processors maintain ISO 9001 certification for quality systems. |

Selection Considerations for International Procurement

Choosing 5052 H32 aluminum sheet for marine applications is usually straightforward, but international procurement adds practical variables that influence performance and cost.

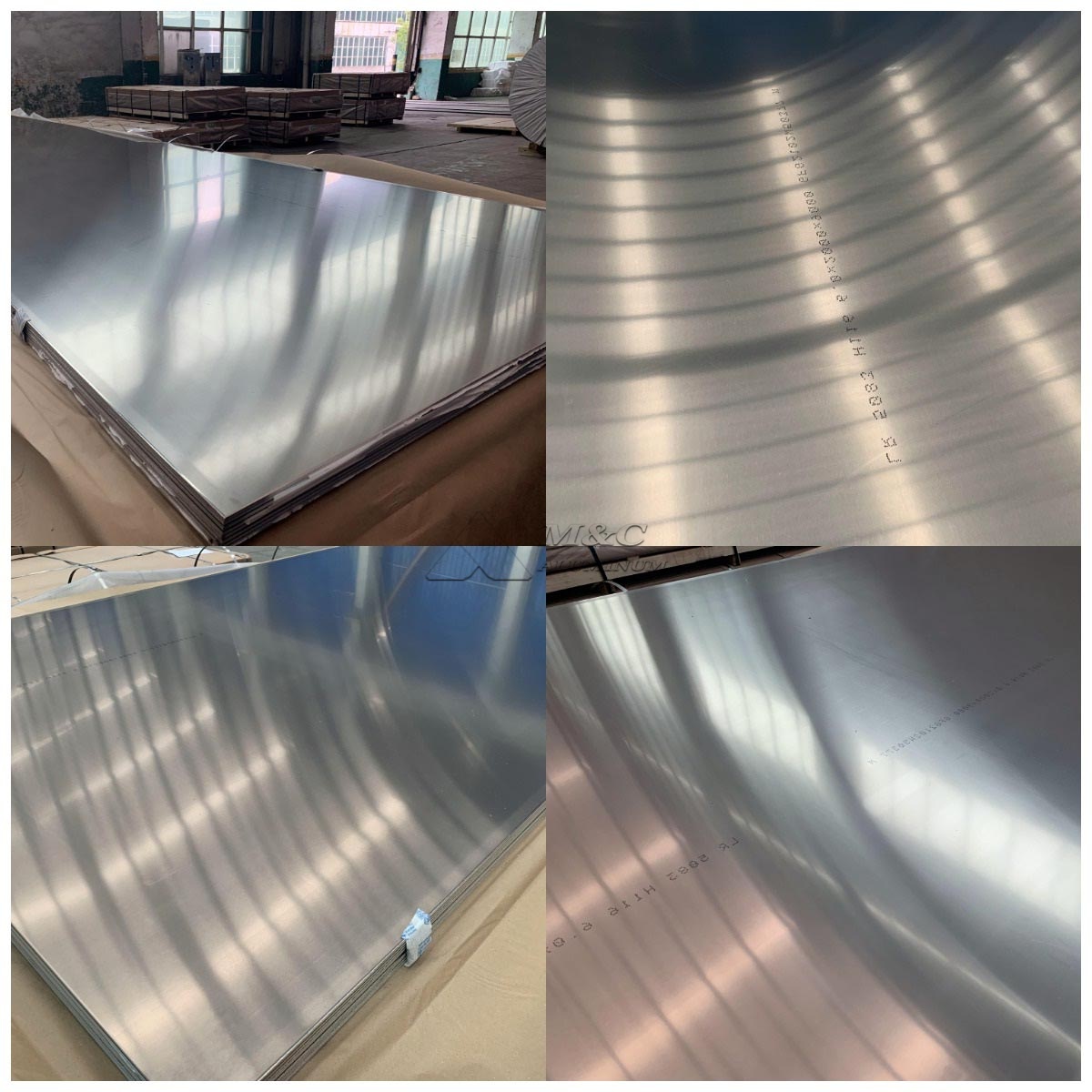

Thickness, flatness, and surface expectations

Marine panels and fabricated enclosures often require consistent flatness to minimize fit-up time. Surface requirements should be clarified early, especially if the sheet will be anodized, left mill-finished, or coated. Streaks, roll marks, and handling scratches can translate into rework costs.

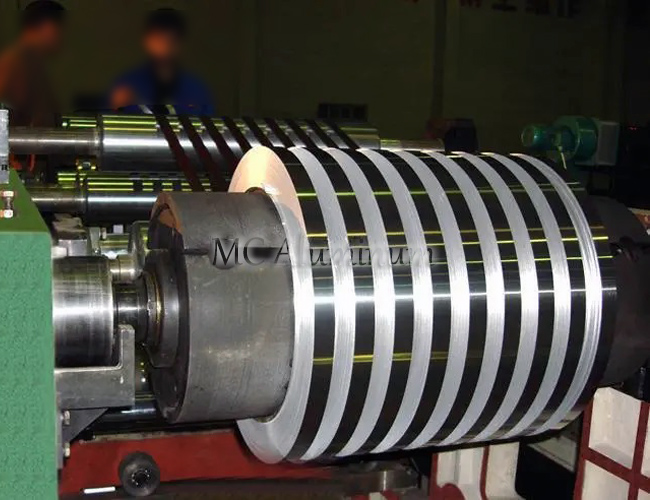

Temper consistency and forming yield

Even within the same temper designation, forming behavior can vary due to processing routes and coil-to-coil variation. If your parts include tight bends or cosmetic surfaces, it is common to align on sample approval and define acceptable tolerances in purchasing documentation.

Corrosion design fundamentals

5052 H32 provides strong baseline corrosion resistance, but marine durability still depends on design and installation details:

Avoid crevices that trap seawater.

Provide drainage and ventilation.

Isolate dissimilar metals with washers, sleeves, sealants, or coatings.

Specify appropriate coatings where abrasion or chemical exposure is expected.

Summary: Where 5052 H32 Fits Best in Marine Engineering

5052 H32 aluminum sheet is a widely used solution for marine applications where saltwater corrosion resistance, weldability, and dependable forming performance must be balanced with cost and availability. Its Al-Mg alloy chemistry supports long-term durability in coastal and marine atmospheres, while the H32 temper offers a practical midpoint between the softness of annealed material and the higher strength of more heavily strain-hardened tempers.

For overseas buyers sourcing marine grade aluminum sheet, 5052 H32 is most often specified for fabricated panels, brackets, covers, housings, and other sheet-based components that benefit from consistent forming and corrosion resistance. Careful temper selection, well-controlled fabrication practices, and corrosion-conscious design details are the main factors that convert the alloy choice into reliable service life in real marine environments.

Contact Us