5083 Aluminum Sheet For Offshore Platforms

Offshore structures operate in an environment defined by continuous salt spray, high humidity, intermittent immersion, cyclic loading, and strict safety requirements. Weight reduction is also a persistent design driver, as every tonne saved can translate into lower installation loads, reduced topside mass, and improved operational efficiency.

As a manufacturer producing marine-grade aluminum plate and sheet in the 5xxx series, we supply 5083 aluminum sheet for offshore platforms where designers require a combination of seawater corrosion resistance, weldability, and reliable mechanical performance. In this article, we explain what 5083 alloy is, which tempers are typically specified for offshore use, how we manufacture and control quality, and how our 5083 sheet performs in real platform scenarios.

Why 5083 Aluminum Is Selected for Offshore Platform Structures

5083 is an Al-Mg-Mn alloy widely recognized as a marine grade aluminum plate solution. In offshore platform fabrication, it is commonly chosen for:

Excellent resistance to seawater corrosion and marine atmospheres.

Good strength at moderate thickness without requiring heat treatment.

Strong weldability for large fabricated assemblies, panels, and stiffened structures.

Stable properties in low temperature service, which is relevant for certain offshore regions.

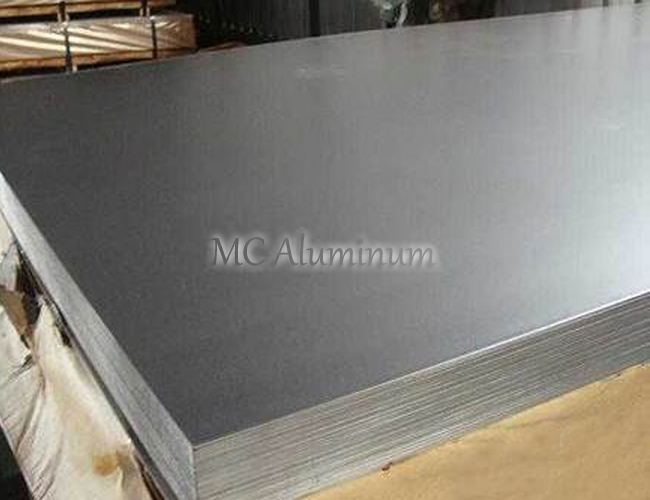

From a manufacturing perspective, the alloy is also well suited to rolling into medium and heavy gauges with consistent flatness and surface quality, which helps fabricators maintain dimensional control during cutting, forming, and welding.

Material Overview: 5083 Alloy and Common Offshore Tempers

5083 belongs to the 5xxx series, where magnesium is the main strengthening element. For offshore platforms, the most common tempers are:

5083-H116 aluminum sheet: frequently specified for marine exposure where enhanced corrosion performance is expected.

5083-H321 aluminum plate: commonly used when a controlled strain-hardened condition is required.

Other strain-hardened states (project dependent) may also be requested based on forming and fabrication needs.

When buyers evaluate 5083 aluminum sheet for offshore platforms, the selection typically balances three factors:

Design strength requirements and thickness.

Corrosion exposure category (splash zone, atmospheric, enclosed areas).

Welding procedures and the required post-weld performance.

If your project includes multiple structural zones, we can recommend temper and thickness combinations to match fabrication routes while keeping the BOM streamlined.

Typical Technical Parameters (Factory Supply Range)

The table below summarizes the technical supply parameters we routinely manufacture for offshore platform projects. Specific requirements are confirmed per purchase order and applicable standards.

| Item | Typical Supply Range / Notes |

|---|---|

| Alloy | 5083 |

| Temper (common) | H116, H321 (others on request) |

| Product form | Aluminum sheet and plate |

| Thickness | 1.5 mm to 150 mm (project dependent) |

| Width | Up to 2500 mm (wider by evaluation) |

| Length | Up to 12000 mm (cut-to-length available) |

| Surface | Mill finish, controlled surface for marine use; protective film optional |

| Flatness control | Leveling and process control per thickness; improved flatness options available |

| Welding suitability | Excellent for MIG/TIG with appropriate filler selection |

| Corrosion performance | Designed for marine atmospheric and seawater-related exposure; temper selection matters |

| Typical inspections | Chemistry, mechanical tests, ultrasonic testing (UT) for plate, dimensional and visual checks |

For buyers comparing specifications across suppliers, the critical point is consistency: chemical composition control, plate internal quality (especially for thicker plate), and repeatable mechanical performance across heat/coil lots.

Manufacturing Capabilities: Rolling, Heat Control, and Finishing

We manufacture 5083 sheet and plate through controlled melting, alloying, casting, and rolling processes designed for marine-grade output. Key capability areas include:

Melting and Composition Control

We control magnesium and manganese targets within the alloy specification to support strength and corrosion performance. Each melt is tracked with heat numbers for full traceability.

Hot Rolling and Cold Rolling (Gauge Dependent)

Plate and heavy gauge: processed primarily via hot rolling with controlled reduction schedules.

Sheet and medium gauge: may include cold rolling to achieve tighter thickness tolerance and improved surface.

Leveling and Flatness

Offshore platform fabrication often involves CNC cutting, welding, and assembly of large panels. Flatness affects fit-up time and weld distortion control. We apply leveling procedures matched to thickness, and we can supply enhanced flatness by request when projects require tight assembly tolerances.

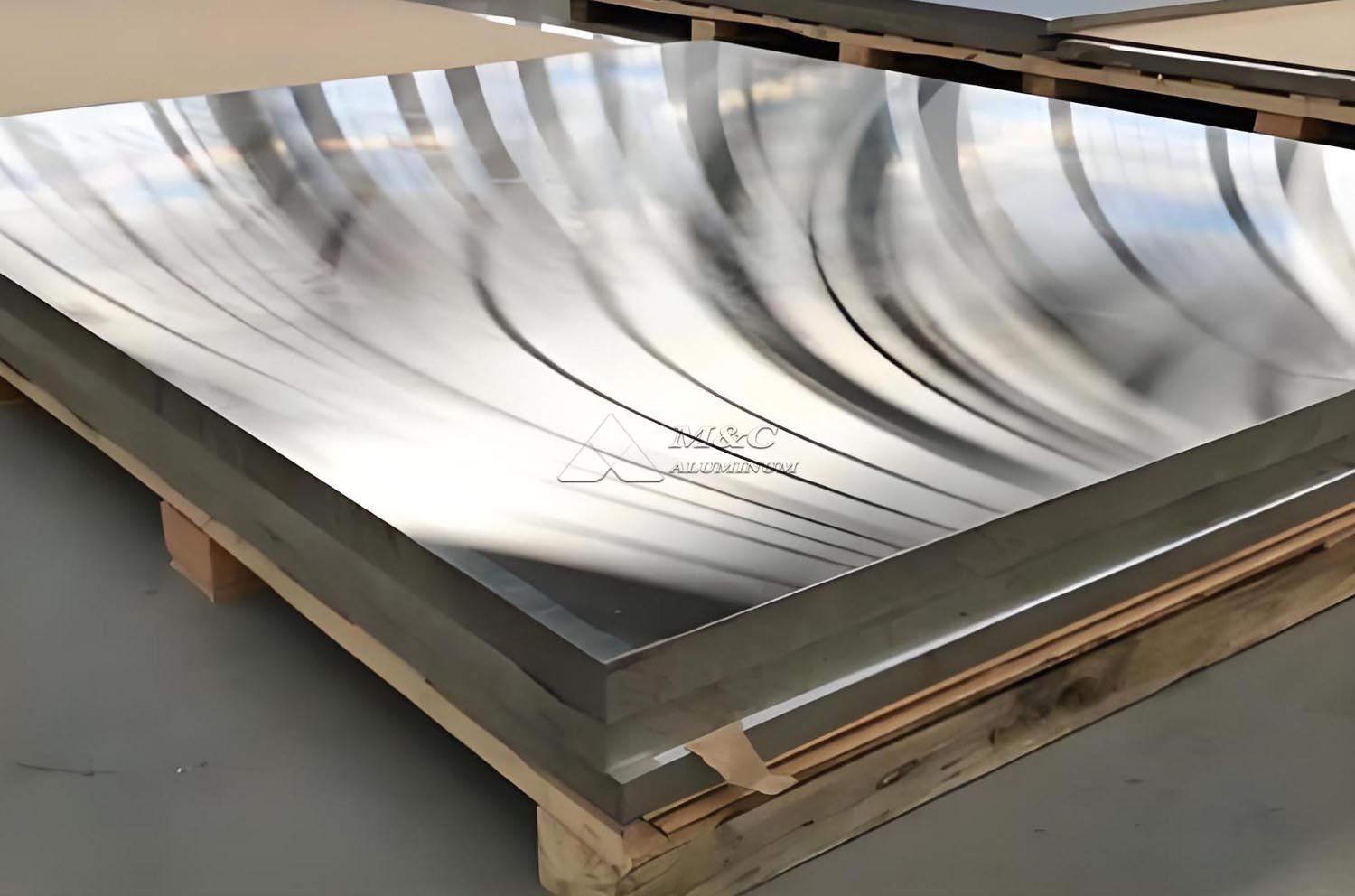

Surface Quality for Marine Projects

For offshore use, surface quality is not only cosmetic. Surface defects can complicate coating performance and inspection. We supply plates and sheets with controlled surface cleanliness and can provide protective PVC film for handling-sensitive applications.

Quality Control, Standards, and Documentation

Offshore platform supply chains typically require strict documentation and repeatable inspection routines. Our QC system focuses on both compliance and process stability.

Standards and Typical Compliance Scope

We supply 5083 sheet and plate to commonly used international aluminum product standards. Where offshore classification is required, we support documentation aligned with project needs, including DNV 5083 aluminum sheet related requests when specified in the contract documents.

Routine Inspection and Testing

Depending on thickness and application, our inspection scope can include:

Chemical composition verification per heat.

Mechanical testing per lot (tensile properties as required by standard/temper).

Dimensional inspection (thickness, width, length, squareness).

Visual inspection for surface defects.

Ultrasonic testing (UT) for plate where internal quality is critical.

Traceability controls: heat number, lot identification, and test reports.

Mill Test Reports and Traceability

We provide mill test reports (MTR) and maintain traceability from casting through rolling and finishing. For offshore projects, stable traceability is important for audits, welding procedure qualification records, and long-term asset documentation.

Customization Options for Offshore Platform Fabrication

Offshore fabricators often need material that is ready for cutting and assembly with minimal rework. We support customization options such as:

Cut-to-length and width trimming to reduce on-site scrap.

Thickness tolerance targeting for critical panels.

Protective film for handling and marking control.

UT level or inspection scope customization for thicker plates.

Batch planning for consistent properties across large projects.

If your design includes multiple alloys, we can also supply related Aluminum Sheets categories to consolidate sourcing, while keeping mechanical and corrosion requirements aligned with each structure zone.

Application Scenarios on Offshore Platforms

5083 aluminum sheet and plate are specified across offshore assets where corrosion resistance and weldability are priorities. Typical scenarios include:

Topsides and Structural Fabrications

Skid frames and support structures (where aluminum is selected for weight reduction)

Stiffened panels and enclosures

Walkways, stairs, ladders, and access structures

Marine-Exposed Components

Splash-zone adjacent elements where seawater spray and salt deposition are frequent

Deck-related components and ancillary structures

Helideck and Safety-Related Structures

Where applicable, aluminum may be chosen to reduce mass while meeting structural and corrosion requirements. Final selection depends on project specifications, fire and safety requirements, and coating systems.

Modular Offshore Units

5083 sheet is also used in modular builds where panel fabrication and welding efficiency affect schedule. Consistent flatness and predictable welding behavior help reduce assembly time.

For buyers evaluating alternative marine alloys in the same family, our 5083 Aluminum sheet supply program supports common offshore dimensions and tempers with repeatable documentation.

Advantages Versus Common Alternatives (Engineering-Focused)

When offshore engineers compare material options, the decision is rarely based on one property alone. Below is how 5083 sheet and plate generally compare with commonly considered alternatives.

Versus Standard Carbon Steel

Lower density supports weight reduction strategies.

Higher inherent corrosion resistance in marine atmospheres can reduce dependency on heavy coating systems (final coating strategy remains project-specific).

No rust staining, which is beneficial for exposed architectural and operational areas.

Versus Heat-Treatable High-Strength Aluminum Alloys

Better weldability in many practical fabrication scenarios.

More stable corrosion behavior in marine exposure for the intended tempers.

Simplified processing because strength is achieved through alloying and strain hardening rather than solution heat treatment.

Versus Lower-Magnesium General-Purpose Aluminum Alloys

Improved marine corrosion suitability for offshore exposure categories.

Higher strength potential in commonly used marine tempers, supporting thinner gauge selection where design allows.

Material selection must always be validated against structural calculations, fatigue considerations, welding procedures, and classification requirements. We support customers by providing data packages and process consistency that reduce engineering uncertainty during qualification.

Supply Stability, Technical Support, and Long-Term Cooperation

Offshore platform projects are schedule-driven and documentation-heavy. As a manufacturer, our objective is to provide a stable, traceable supply of 5083 aluminum sheet for offshore platforms with predictable lead times and consistent quality.

We support customers with:

Technical confirmation of temper, thickness, and inspection scope.

Lot traceability and compliant test documentation.

Production planning for phased deliveries and multi-module builds.

Manufacturing feedback for forming, cutting, and welding considerations.

For long-term partners, we can align stocking or rolling plans to your framework contracts to reduce procurement risk and maintain consistent properties across project stages. If you share your platform specification, drawings, and inspection requirements, we will propose a supply specification and QC plan suitable for your engineering and fabrication workflow.

Contact Us