5083 H116 Aluminum Sheet Specifications

Introduction: Why 5083 H116 Matters in Marine and Corrosive Service

As a manufacturer of 5xxx series aluminum sheet and plate, we supply 5083 H116 aluminum sheet for projects where corrosion resistance, weldability, and reliable strength in seawater exposure are primary requirements. H116 is a strain-hardened temper developed specifically for marine service, with controlled processing to reduce susceptibility to exfoliation and intergranular corrosion compared with general-purpose work-hardened tempers.

Typical customer applications include ship hulls and superstructures, offshore platforms, decks and walkways, pressure and storage components, and transport structures operating in salt spray or industrial atmospheres. For buyers comparing marine grade options, marine grade aluminum 5083 is frequently specified because it balances strength and fabrication efficiency without requiring heat treatment.

Material Overview: Alloy 5083 and the H116 Temper

Alloy family and chemistry intent

5083 is an Al-Mg-Mn alloy. Magnesium contributes solid-solution strengthening and improved corrosion resistance in many environments, while manganese helps control grain structure and enhances strength consistency. Because 5083 is non-heat-treatable, its strength is achieved through work hardening and process control.

From a manufacturing standpoint, the H116 temper is selected when the end use demands:

Stable mechanical properties in thick gauges.

High resistance to seawater corrosion and marine atmospheric exposure.

Good weldability with common filler alloys.

Consistent plate and sheet flatness for downstream cutting and forming.

What H116 signifies

H116 is a strain-hardened temper intended for products where improved corrosion resistance is required. In practice, it involves controlled rolling and stabilization steps so that the material meets marine corrosion performance requirements used in standards such as ASTM B928.

When customers specify 5083 H116 aluminum plate versus H321 or other tempers, the decision is often driven by certification routes, project specifications, and thickness range.

5083 H116 Aluminum Sheet Specifications

We produce 5083 H116 sheet and plate to customer standards and common international specifications for marine service. Below is a consolidated view of typical requirements used by engineering buyers. Final supply is always confirmed by the purchase order, agreed standard, and inspection plan.

Standards and designations

| Item | Typical specification or designation |

|---|---|

| ASTM marine sheet and plate | ASTM B928/B928M (5083 H116) |

| General aluminum sheet and plate | ASTM B209/B209M (where applicable by project) |

| EN designation | EN AW-5083 |

| EN temper designation | H116 |

| Marine classification use | Common in shipbuilding and offshore structures (project-driven) |

Chemical composition (typical limits, reference)

| Element | Typical limit, wt% |

|---|---|

| Mg | 4.0 to 4.9 |

| Mn | 0.4 to 1.0 |

| Cr | 0.05 to 0.25 |

| Si | max 0.40 |

| Fe | max 0.40 |

| Cu | max 0.10 |

| Zn | max 0.25 |

| Ti | max 0.15 |

| Al | balance |

Note: Composition limits depend on the governing standard and mill certification method. We confirm chemistry by spectrometer testing and provide heat-based traceability.

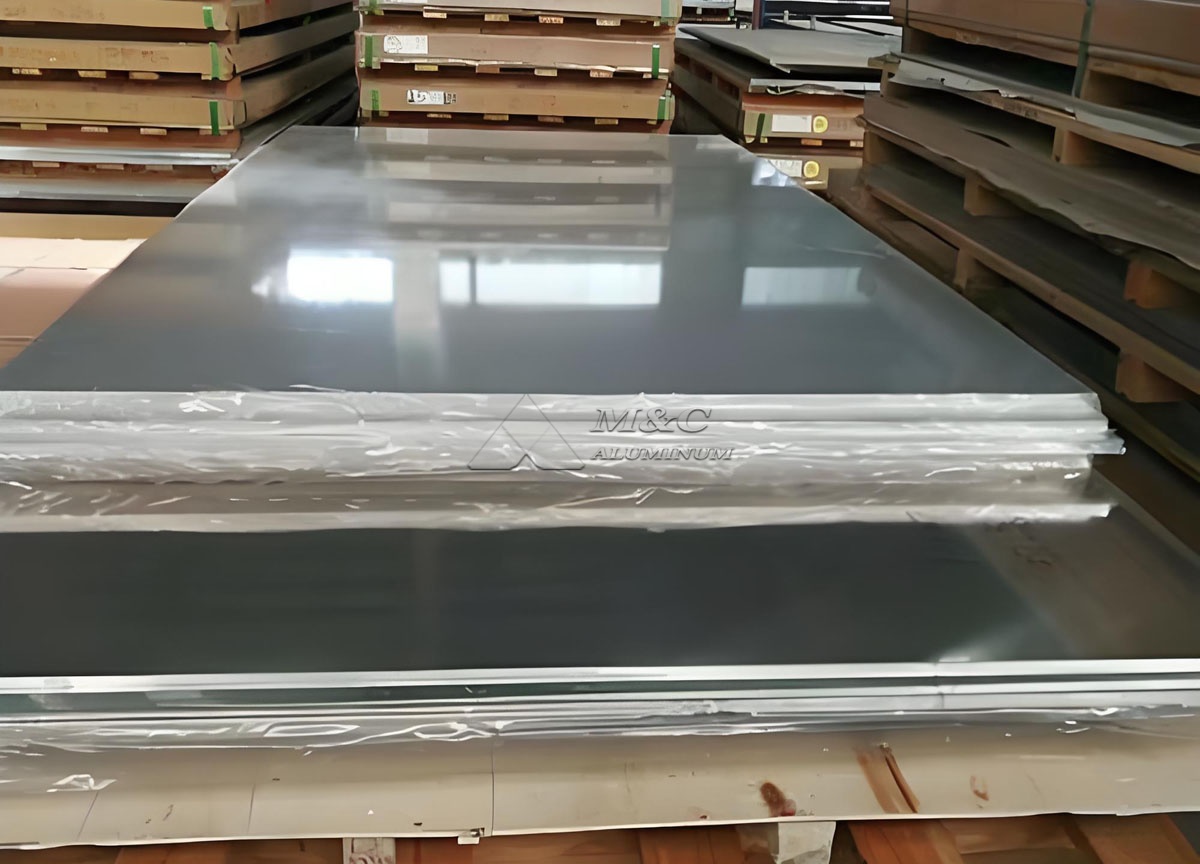

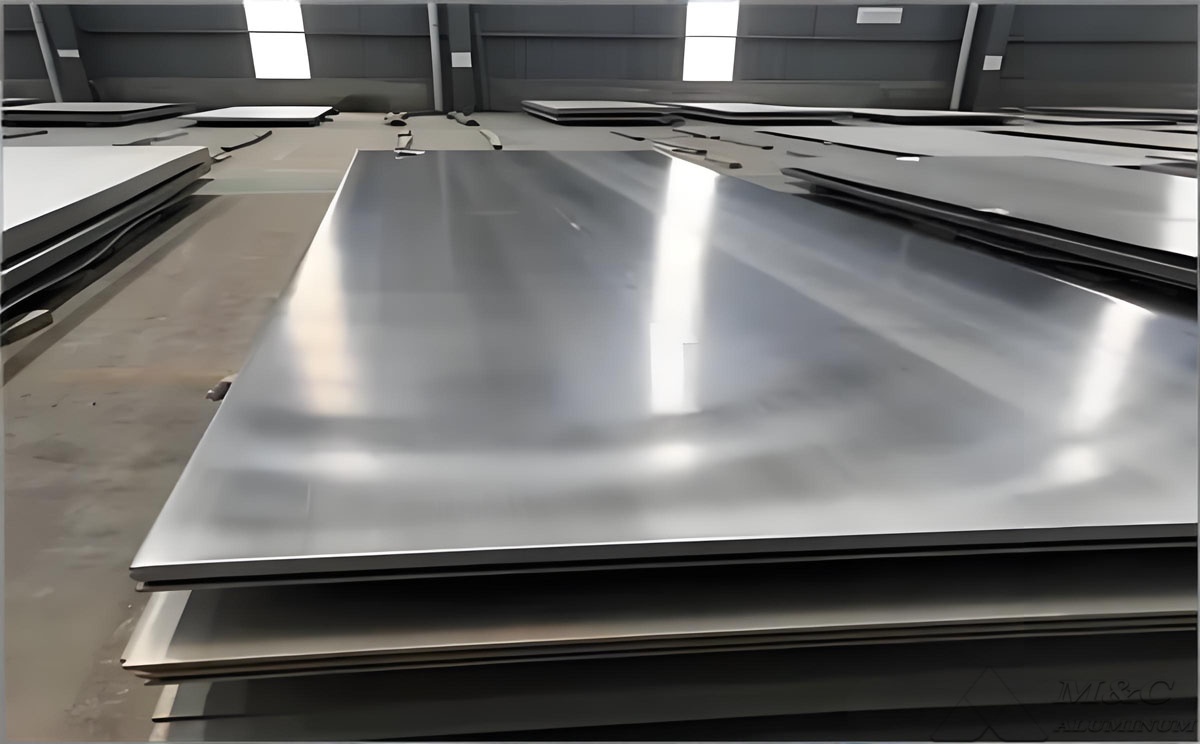

Dimensional supply range (factory capability)

| Parameter | Typical supply range |

|---|---|

| Product form | Sheet and plate |

| Thickness | 1.5 to 80.0 mm (inquiry-dependent) |

| Width | Up to 2200 mm |

| Length | Up to 12000 mm |

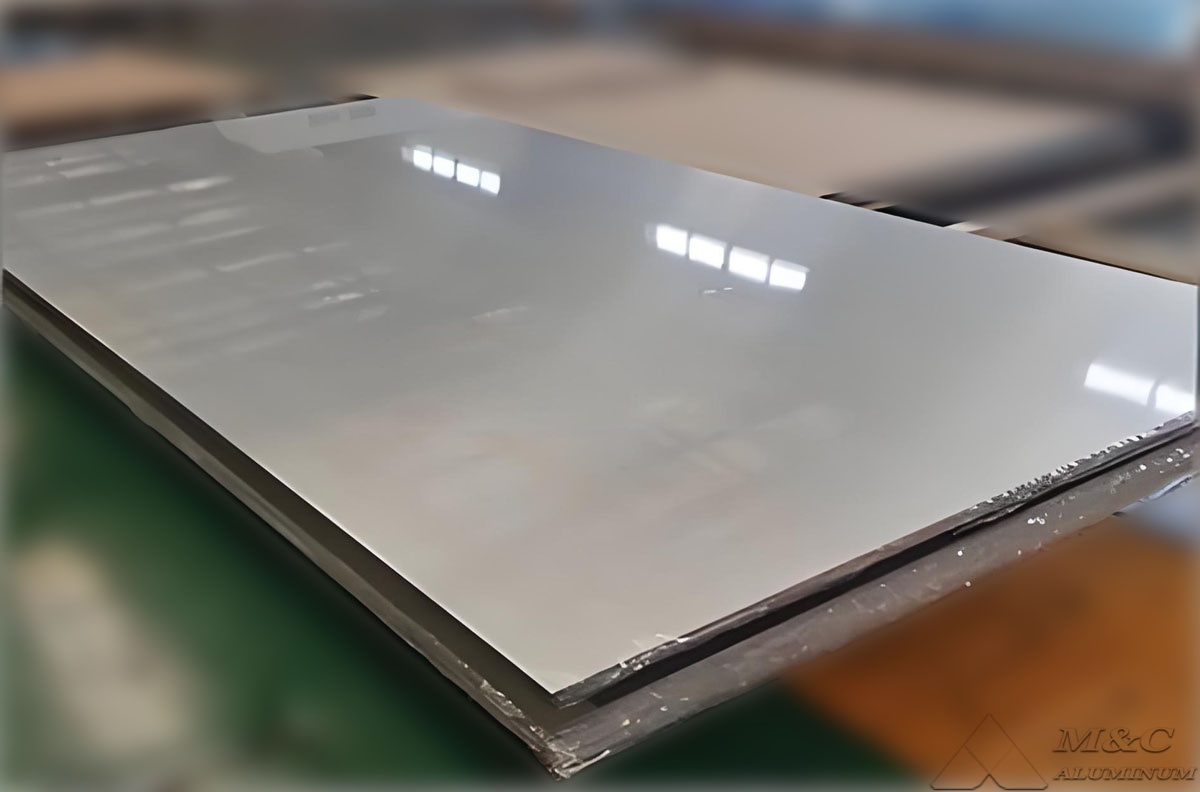

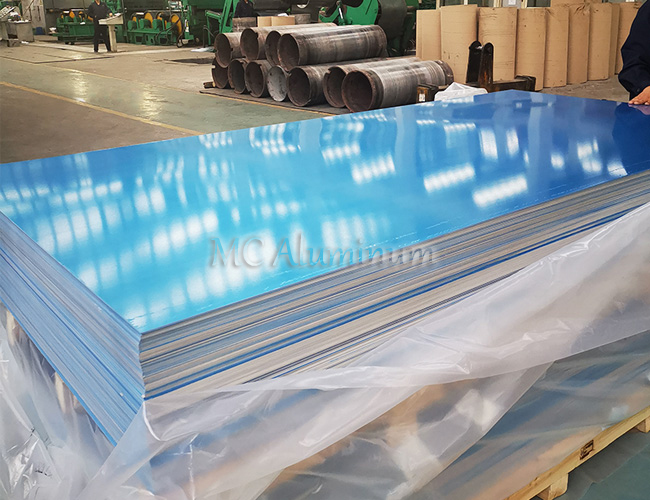

| Surface | Mill finish standard, one-side protective film optional |

Mechanical properties (typical reference values)

Mechanical properties vary with thickness and standard. The table below provides typical values used for engineering estimation. Certified values are provided on the mill test certificate per the ordered standard.

| Property | Typical value range |

|---|---|

| Tensile strength, Rm | 300 to 360 MPa |

| Yield strength, Rp0.2 | 200 to 260 MPa |

| Elongation, A50 | 10 to 16% |

| Hardness (Brinell, HBW) | approx. 80 to 95 |

Corrosion performance expectations

| Environment | Performance expectation |

|---|---|

| Seawater immersion and splash zones | Very good resistance when properly designed and maintained |

| Marine atmosphere (salt spray) | Very good |

| Industrial atmosphere | Good to very good, depends on pollutants |

| Galvanic couples | Requires isolation design when joined to dissimilar metals |

Product Features and Performance in Fabrication

Weldability

5083 H116 is widely used in welded structures. It is compatible with common MIG and TIG procedures used in shipbuilding and offshore fabrication. As with all aluminum welding, joint design, cleanliness, and heat input control are essential for achieving consistent mechanical performance.

Formability and machining

Compared with softer tempers, H116 provides higher strength, which can slightly reduce tight-radius forming capability. For many marine structures, bending is performed with validated radius guidelines based on thickness and rolling direction. Machining is generally stable when using sharp tools and appropriate lubrication.

Strength-to-weight efficiency

For weight-sensitive structures, 5083 H116 provides a practical balance: stronger than general-purpose 3xxx series sheet, and more corrosion-resistant in seawater than many heat-treatable alloys when welding is involved.

Manufacturing Capabilities, Quality Control, and Traceability

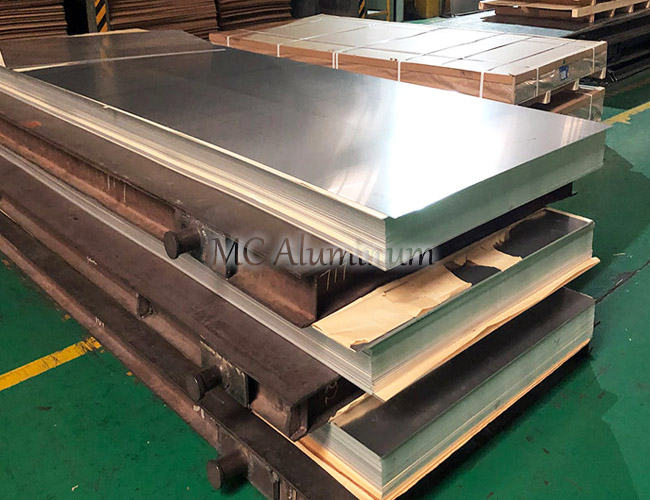

As a producing mill, we control the full route from slab preparation through hot rolling, cold rolling (as applicable), leveling, cutting, inspection, and packing. For marine projects, process stability and documentation are as important as the nominal alloy.

Key manufacturing controls

Thermomechanical processing control to achieve H116 temper and consistent mechanical properties.

Flatness management through leveling and tension control to support CNC cutting and panel fabrication.

Surface inspection to reduce downstream rework for visible marine structures.

Edge quality control for plate products intended for automated welding lines.

Quality inspection and certification

| QC item | Typical method |

|---|---|

| Chemical analysis | Spectrometer (heat-based) |

| Tensile testing | Per standard, thickness-based sampling |

| Dimensional checks | Thickness, width, length, squareness, flatness |

| Surface quality | Visual inspection under controlled lighting |

| UT testing (when specified) | Ultrasonic inspection per project requirement |

| Documentation | Mill test certificate with heat number traceability |

Standards alignment

We commonly manufacture 5083 H116 to ASTM B928 for marine service, and we can support EN AW-5083 H116 documentation packages when required by the project. For buyers sourcing multiple alloys, our broader Aluminum Sheets portfolio allows consistent procurement and packaging standards across a project.

Customization Options for Engineering Projects

Marine and offshore fabrication often requires more than standard mill sizes. We support customization based on production feasibility and inspection scope.

| Customization item | Options |

|---|---|

| Cut-to-size | Fixed length, nested cutting plans, blanks for profiling |

| Surface protection | PVC film, interleaving paper, anti-scuff packing |

| Tolerances | Project-specific tolerances subject to gauge and width |

| Marking | Heat number, PO number, part ID, stencil or label |

| Additional testing | UT, bend tests, corrosion-related documentation (as specified) |

For customers ordering this alloy regularly, we can establish a stable rolling schedule for recurring thicknesses and widths, supporting shorter lead times and consistent mechanical performance.

Application Scenarios and Target Industries

Shipbuilding and marine structures

5083 H116 is a standard selection for:

Hull plating and side shells.

Decks, ramps, gangways, and superstructures.

Marine partitions and structural panels.

Offshore and coastal infrastructure

Platform modules and walkways.

Coastal equipment housings.

Corrosion-critical structural components.

Transportation and heavy fabrication

Vehicle bodies exposed to de-icing salts.

Containers and structural parts where weldability and corrosion resistance are required.

When customers need a dedicated product page for procurement alignment, our 5083 Aluminum sheet specification set can be referenced alongside project drawings and inspection requirements.

Conclusion: Stable Supply, Engineering Support, and Long-Term Cooperation

5083 H116 aluminum sheet is a proven marine grade material for shipbuilding, offshore structures, and corrosive-service fabrication. As a manufacturer, we focus on controlled temper processing, thickness consistency, flatness, and full traceability to support engineering acceptance and efficient downstream production.

For project inquiries, we support specification review (ASTM B928 or EN AW-5083 H116), cut-to-size planning, inspection documentation, and repeat-order scheduling. Our goal is stable long-term supply and technical coordination across the full lifecycle of your marine and industrial programs.

Contact Us