6061 & 6063 Aluminum Round Tubes

6061 and 6063 aluminum tubes are two commonly used aluminum alloy tubing products in industrial applications. With excellent mechanical properties, good machinability, and strong corrosion resistance, they are widely used in structural construction, transportation, machinery manufacturing, electronics, aerospace, and more.

What is 6061 Aluminum Round Tube?

6061 aluminum tube is a heat-treatable alloy with good formability, weldability, and machinability. It offers medium strength and retains good workability even after annealing. It is commonly anodized to enhance corrosion resistance.

MC Aluminum supplies 6061 aluminum tubes in various wall thicknesses and diameters.

Mechanical Properties of 6061:

Ultimate tensile strength: ≥205 MPa

Compressive yield strength: 55.2 MPa

Elastic modulus: 68.9 GPa

Flexural strength: 228 MPa

Chemical Composition (%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

What is 6063 Aluminum Round Tube?

6063 aluminum tubing has excellent extrudability, making it suitable for producing complex cross-sectional shapes. It offers outstanding corrosion resistance and surface finishing properties. As a heat-treatable alloy, it has high impact toughness and no tendency for stress corrosion cracking—making the Al-Mg-Si series the only heat-treatable aluminum alloy group without stress corrosion concerns.

Mechanical Properties of 6063:

Tensile strength σb (MPa): ≥205

Yield strength σp0.2 (MPa): ≥170

Elongation δ5 (%): ≥7

Note: Room temperature, longitudinal mechanical properties for rods ≤12.5mm in diameter

Chemical Composition (%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | remainder |

Specifications

| Alloys | 6061, 6063 |

| Tempers | T5, T6, T651, etc. |

| Outer Diameter | φ6mm ~ φ300mm |

| Wall Thickness | 0.5mm ~ 20mm |

| Length | Usually 6 meters, customizable lengths available |

| Surface Treatment | Anodizing, electrophoresis coating, sandblasting, polishing, painting |

| Processing | Turning, drilling, welding, bending, etc. |

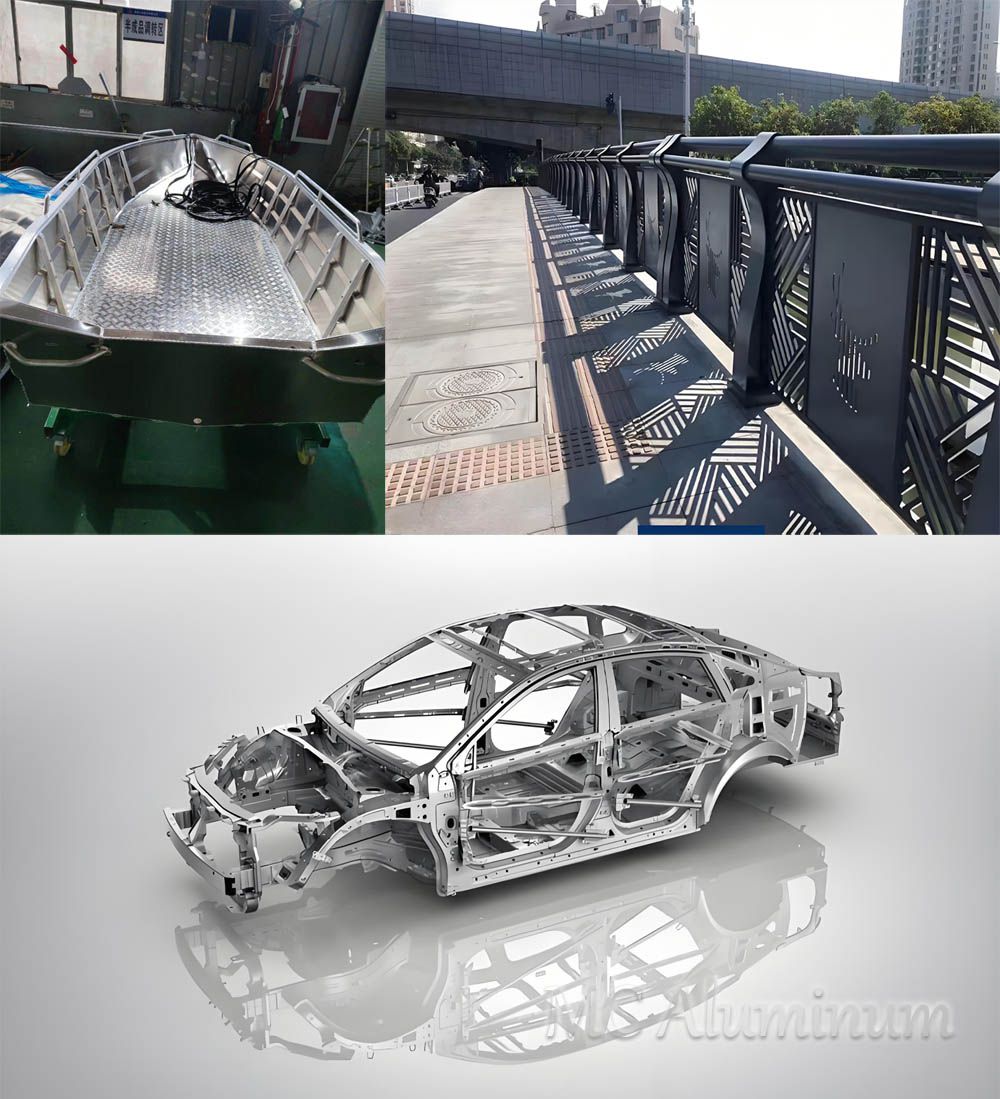

| Applications | Shipbuilding, automotive, aerospace, architectural decoration, etc. |

| MOQ | 1–3 tons |

What’s the Difference Between 6061 and 6063 Aluminum Tubes?

While both 6061 and 6063 anodized aluminum tubes share traits like corrosion resistance and a favorable strength-to-weight ratio, key differences make them suitable for distinct applications.

6061-T6 aluminum tubes are known for their strength, weldability, machinability, formability, and overall versatility. They are commonly used in structural construction, transportation, machinery, electronics, and aerospace.

6063 aluminum round tubes, on the other hand, are prized for their thermal treatability, weldability, and exceptional aesthetic value. They are often used in architectural and extrusion applications, including window and door frames, curtain walls, railings, and radiators.

As a large aluminum processing manufacturer, MC Aluminum specializes in the production of aluminum sheets, aluminum foils, aluminum strips, aluminum coils, aluminum profiles and other products. The aluminum tubes produced include 6061, 6063, 7075, 7A04, 5083, 5A06, 5052, 2024, 2017, 3003, 1100, 1070, etc. The thickness/diameter/wall thickness range is: 0.10mm-600mm, length 30mm-6000mm, etc., which can be customized according to customer needs. Products are exported to many countries overseas, with direct sales from the manufacturer, preferential prices, samples provided, and factory visits.

Contact Us