China Armored Cable Aluminum Strip Manufacturer

Armored cables play a critical role in power transmission and distribution, and their metallic outer sheath directly impacts mechanical strength, corrosion resistance, and installation safety. Among various sheath materials, aluminum strip has become one of the preferred options due to its lightweight nature, strong corrosion resistance, and excellent formability.

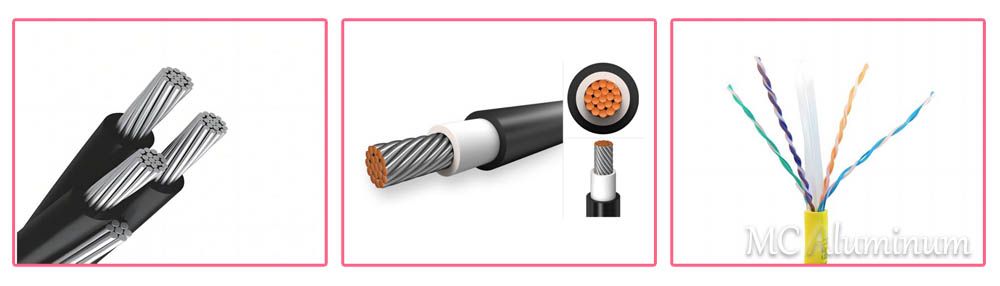

The basic structure of a cable consists of the conductor, insulation layer, shielding layer, and outer sheath. The shielding layer is essential for ensuring signal transmission quality, and aluminum-plastic composite tape serves as the core material of this functional layer.

In armored cable structures, the aluminum strip is positioned around the shielding layer typically applied directly over the insulation and beneath the outer sheath. It effectively blocks external electromagnetic interference without significantly increasing the cable's diameter or weight, while also providing moderate mechanical protection.

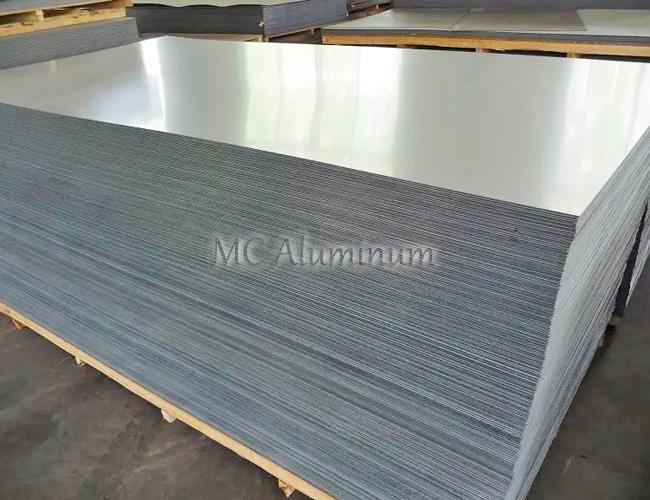

MC Aluminum manufactures high-quality aluminum strips for armored cables. Common grades include 1060, 1100, 3003, 5052, and 5754 aluminum strip. Other alloys can be customized based on specific processing requirements.

Technical Specifications

| Alloy Grades | 3003, 5052, 1100, 1350, 5754, 1060, etc. |

| Temper | O (soft), H12 / H14 / H18 (semi-hard) |

| Width | 30 mm - 800 mm |

| Thickness | 0.15 mm - 3.0 mm |

| Thickness Tolerance | ±0.01 mm |

| Width Tolerance | ±0.20 mm |

| Surface Finish | bright, brushed, anodized, coated |

| Edge Type | slit edge / round edge |

| Paper Core Inner Diameter | 150 mm, 200 mm, 300 mm, 400 mm, 508 mm |

| Outer Diameter | 500 - 800 mm |

| Conductivity | above 30% IACS |

| Density | approx. 2.70 g/cm³ |

| Coil Weight | 500 kg - 2000 kg |

| Application | aluminum strip for cable armoring |

| MOQ | 1-3 tons |

Recommended Aluminum Alloy Grades for Cable Armoring

1xxx Series (Pure Aluminum)

These grades contain at least 99% aluminum. They feature superior corrosion resistance and excellent ductility, but their mechanical strength is relatively low, making them unsuitable for heavy-duty armored cables.

5xxx Series (Al-Mg Alloys)

These alloys contain magnesium as the main alloying element, with a minimum of 95% aluminum. They offer excellent strength, good formability, and superior corrosion resistance ideal for heavy-duty armored cable applications.

8xxx Series

These alloys provide higher tensile strength and enhanced mechanical performance, making them suitable for cable structures requiring greater strength and durability.

Advantages of Aluminum Strip for Armored Cables

1. Corrosion Resistance:

Aluminum naturally forms a dense oxide film, providing long-lasting protection against moisture and chemical exposure.

2. High Ductility:

Allows easy wrapping, bending, and forming during cable manufacturing without cracking or breaking.

3. Lightweight:

Significantly lighter than steel tape, reducing overall cable weight and transportation costs.

4. Good Weldability and Coating Compatibility:

Aluminum strip can be welded or surface-treated to enhance service life and adhesion of protective coatings.

5. Excellent Electrical Conductivity:

As a good conductor, aluminum provides superior shielding performance against high-frequency electromagnetic interference compared with steel materials.

Applications of Aluminum-Armored Cables

Power cables

Communication cables

Control cables

Submarine or underground cables

Contact Us