What Are the Models of Air Conditioner Fin Aluminum Foil?

In modern air conditioning systems, whether it's a household wall-mounted air conditioner, a central air conditioning system, a heat pump unit, or a refrigerator condenser, a key component is the finned heat exchanger. And the most crucial raw material for finned heat exchangers is the air conditioner fin aluminum foil.

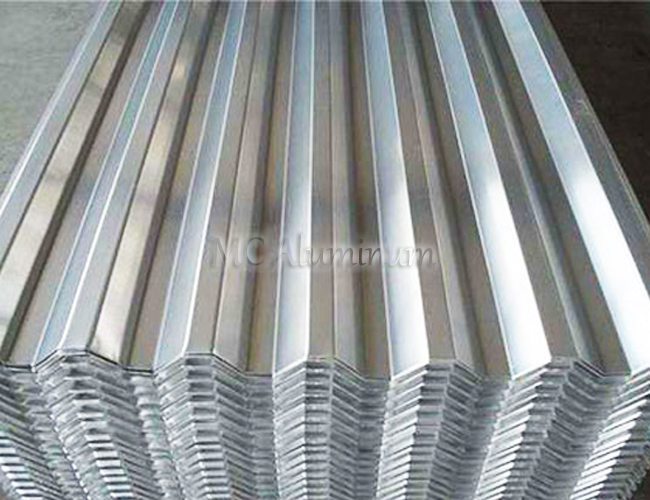

Air conditioner fin aluminum foil is a thin aluminum material, approximately 0.08-0.2 mm thick, mechanically processed into wavy or louvered shapes, and combined with copper or aluminum tubes to form a heat exchanger.

Applications of Air Conditioner Fin Aluminum Foil

Improve Heat Exchange Efficiency: Increases the contact area between air and refrigerant.

Reduce Energy Consumption: High-efficiency fins achieve the same cooling capacity using less energy.

Corrosion Resistance: Prevents oxidation, moisture, and salt spray from degrading performance.

Enhance Durability: Directly impacts the air conditioner's lifespan.

Lightweight: Aluminum's low weight aids energy efficiency and structural optimization.

Models and Performance Specifications of Fin Aluminum Foil

3102 Aluminum Foil:

Used in condensers and evaporators, with excellent corrosion resistance and thermal conductivity. Typical thickness: 0.1-0.15 mm, width: ~1000 mm.

8011 Aluminum Foil:

Suitable for small condensers, evaporators, and automotive ACs. Features high thermal conductivity, good corrosion resistance, and high strength. Typical thickness: 0.15-0.3 mm, width: ~1000 mm.

1100 Aluminum Foil:

Excellent corrosion resistance and thermal conductivity, suitable for various types of ACs. Typical thickness: 0.08-0.2 mm, width: ~1000 mm.

1060 Aluminum Foil:

Good weldability and formability, widely used for manufacturing AC fins. Typical thickness: 0.1-0.3 mm, width: ~1000 mm.

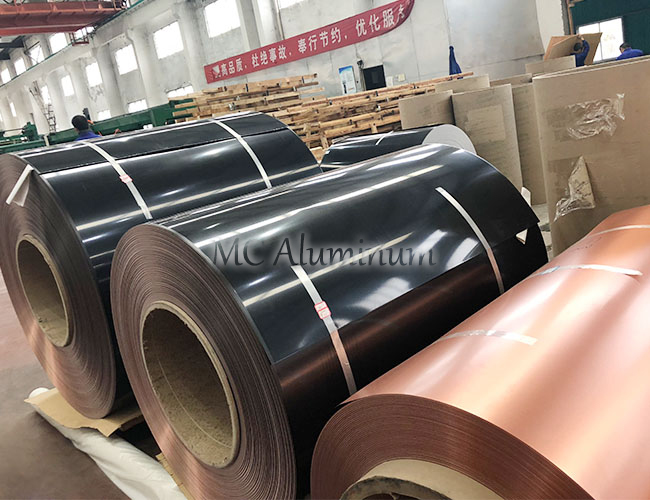

Coating Types for Fin Aluminum Foil

Hydrophilic Aluminum Foil: Surface promotes water spreading, improving heat exchange efficiency.

Hydrophobic Foil: Coating allows water droplets to slide off quickly, suitable for dry or dusty environments.

Anti-Corrosion Foil: Enhances corrosion resistance, extending AC lifespan.

Mold-Resistant Foil: Prevents mold growth, improving indoor air quality.

Self-Lubricating Foil: Improves processing performance, facilitating manufacturing.

Surface Treatment: Plain Foil vs. Hydrophilic Foil

Besides the alloy, surface treatment determines the final product's efficiency.

Plain Foil: Uncoated, low cost, poor hydrophilicity, condensation water can block airflow. Gradually being phased out.

Hydrophilic Aluminum Foil: Coated with anti-corrosion and hydrophilic layers (commonly blue or gold). Condensation water spreads quickly, increasing heat exchange efficiency by ~5% and providing resistance to oxidation ("white rust").

Application Fields

1. Standard household air conditioners

2. High-end energy-saving air conditioners

3. Air conditioners for coastal, high-humidity, and acidic environments

4. Commercial, industrial, and heat pump equipment

5. Refrigerators and dehumidifiers

Quality Standards for Air Conditioner Aluminum Foil

1. Mechanical Properties and Formability

Tensile Strength: Typically 120-175 MPa (depending on H22 or H24 temper). Too high damages molds; too low makes fins too soft.

Elongation: Must be ≥20% for thickness >0.1 mm. High elongation ensures the base does not crack during high flanging.

Cupping Value: Critical indicator. High-quality foil should have ≥6.0-7.0 mm, reflecting excellent deep-drawing capability for high-fin heat exchangers.

2. Hydrophilic Performance

Initial Contact Angle: ≤10°, ensuring water spreads quickly rather than forming beads.

Persistent Hydrophilicity: After aging tests, contact angle must remain ≤20–25°, ensuring no water accumulation over years.

Adhesion: Coating must pass crosshatch or boiling tests, with no peeling or powdering.

3. Dimensional Tolerance and Flatness

Thickness Tolerance: Must be controlled within ±0.005 mm or tighter.

End Quality: Coil ends must be neat, with no telescoping; interlayer misalignment ≤1 mm.

Tension Control: Must unroll flat, without edge waves or central waviness.

4. Surface Appearance

Foil surface must be free of oil, black lines, and deep scratches. For hydrophilic foils, coating color must be uniform, with no missed spots or color variations.

Contact Us