What is color-coated aluminum coil -MC Aluminum

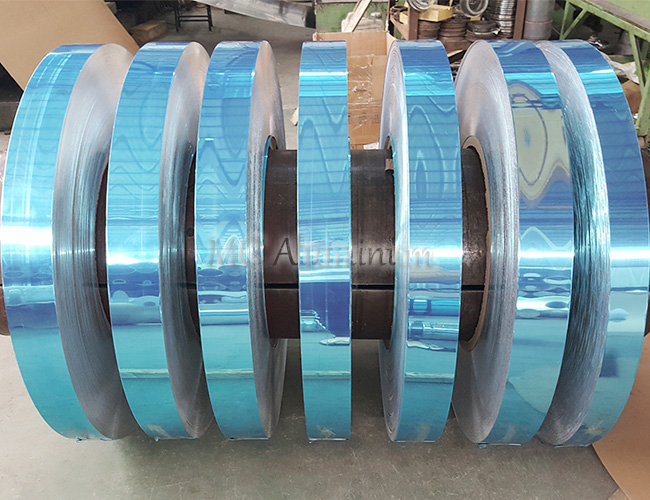

The color-coated aluminum coil is to paint and color the surface of aluminum substrate. Aluminum alloy has very stable performance and is not easy to be corroded. Generally, after special treatment, the surface layer can not fade for at least 30 years. Moreover, because of its low density and high hardness, the weight per unit volume is the lightest among metal materials. Painted aluminum coil has become one of the most popular top decorative materials.

Common ones are polyester coated aluminum coil (PE), fluorocarbon coated aluminum coil (PVDF):

1.Polyester coated aluminum coil

It is a kind of UV-resistant coating. Polyester resin is made of high-molecular polymer containing ester bond in the main chain as monomer, and alkyd resin is added. UV absorbers can be divided into matt and high-gloss series according to glossiness. Especially suitable for indoor decoration and advertisement boards.

2.Coated fluorocarbon aluminum coil

It is made by mixing fluorocarbon resin with fluoroalkyne as the basic monomer, pigment, alcohol ester solvent and auxiliary agent. After being baked at high temperature to form a film, the molecular structure in the coating is tight and has super weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon coatings and nano-fluorocarbon coatings according to the surface film structure. It is especially suitable for the decoration and display of indoor and outdoor decoration in public places, commercial chains, exhibition advertisements, etc.

Common specifications and models of color-coated aluminum coils:

Construction (aluminum-plastic board, aluminum honeycomb, roof wave board, fire-proof veneer, aluminum ceiling, blinds, rolling doors, garage doors, awnings, gutters), electronic appliances (computer cases, electrical panels), lighting, furniture, solar reflectors, air-conditioning ducts, etc.

Common specifications and models of color-coated aluminum coils:

| Alloy | 1100,3003,3004,3105,5052,8011,other alloys are available on request. |

| Thickness | 0.18mm-1.5mm |

| width | <1800mm |

| Coil core diameter | 150mm ,405mm, 505mm, 508mm, 510mm |

Characteristics of color-coated aluminum coils:

1.Flatness: No compound high-temperature indentation on the surface. There is no residual stress on the board surface, and it will not deform after shearing.

2.Decorative: coated with wood grain and stone grain, with realistic physical texture and vivid natural beauty. Designs are made at will, giving customers a wide range of individual choices, enriching the humanistic connotation of products and giving people more beautiful enjoyment.

3.Weathering resistance: the paint pattern made by coating and baking at high temperature has high gloss retention, good color stability and little color difference change. The warranty period of polyester paint is 10 years, and that of fluorocarbon paint is more than 20 years.

4.Mechanical properties: high-quality aluminum, plastic and adhesive are selected, and advanced composite technology is adopted. The product has the flexural and flexural strength required by the decorative board. Under the four-season climate, changes in wind pressure, temperature, humidity and other factors will not cause bending, deformation, expansion, etc.

5.Environmental protection: resistant to saline-alkali acid rain corrosion, will not corrode live toxins, release any toxic gas, and will not cause corrosion of keels and fixings, flame retardancy. Not lower than B1 level according to national regulations.

MC Aluminum has complete product specifications and huge production capacity, which can meet your individual processing needs. MC Aluminum can produce 1-8 series color-coated aluminum coil products and provide you with the latest product quotation. Looking forward to your consultation!

Contact Us