Why Cookware Manufacturers Prefer Anodized Aluminum Circles

In modern kitchens, aluminum cookware has long been a popular choice due to its fast and even heat conduction. However, ordinary aluminum has some limitations, such as being prone to scratching, reacting with acidic or alkaline foods, and having relatively low hardness.

To overcome these limitations and enhance both performance and lifespan, modern cookware manufacturers increasingly prefer high-tech treated substrates - anodized aluminum circles.

Anodized aluminum circles offer excellent corrosion resistance, thermal conductivity, and aesthetic appeal, making them an ideal alternative to traditional stainless steel or enameled materials. They are widely used in woks, frying pans, pressure cookers, rice cooker inner pots, and other kitchen utensils, combining lightweight, durability, and visual appeal, and are considered a primary choice for cookware manufacturing.

What is Anodized Aluminum?

Anodizing is an electrochemical process that artificially generates a thicker, harder, and denser aluminum oxide layer on the surface of the aluminum circle. Unlike the soft aluminum substrate, this oxide layer has very high hardness, with a Mohs hardness up to 9, second only to diamond. It provides exceptional wear resistance and can withstand daily scratches from metal utensils.

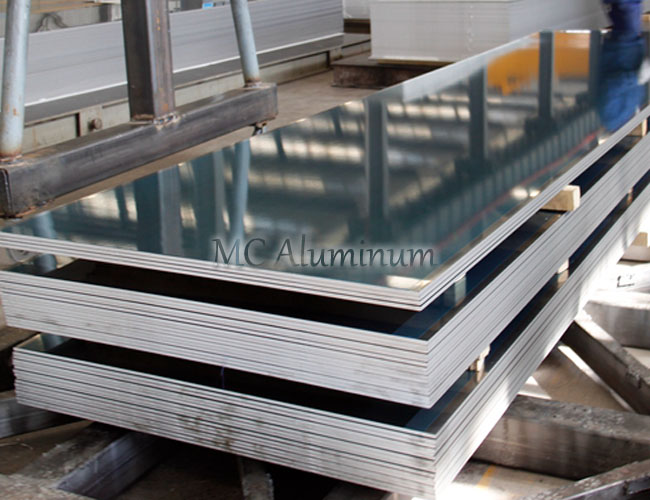

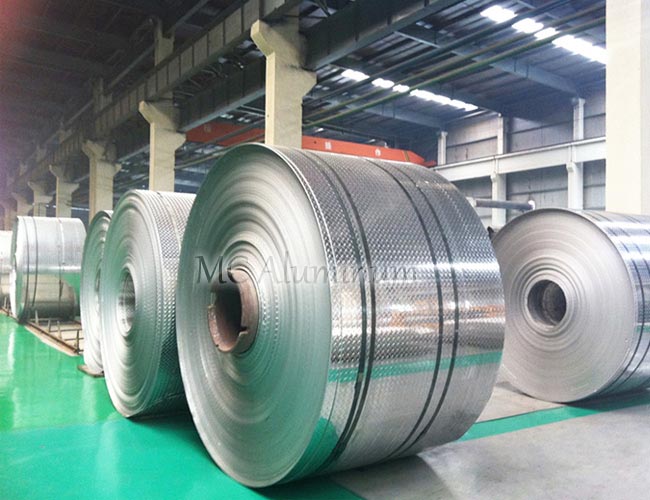

Cookware-grade anodized aluminum circles typically use 1050, 1060, 1100, or 3003 aluminum alloys, offering thicknesses from 0.5mm to 6.0mm and diameters from 100mm to 1200mm.

1050 Aluminum circles : With an aluminum content as high as 99.5%, 1050 aluminum is a typical pure aluminum alloy. It has excellent ductility and thermal conductivity, making it suitable for deep drawing and spinning. It is relatively inexpensive and offers high cost-effectiveness. Commonly used in the production of woks, rice cooker inner pots, and kitchen frying pans.

1060 Aluminum circles : Similar in performance to 1050, but with higher purity (above 99.6%), excellent machinability, and a smooth surface. Commonly used in lightweight cookware, such as induction cooker pots and the bottoms of everyday tableware.

1100 Aluminum circles : Containing a small amount of copper, its strength is slightly higher than 1050 and 1060, and it has better corrosion resistance and thermal conductivity. It can be used to manufacture high-end cookware requiring uniform heat distribution, such as double-layer composite pot bottoms.

3003 Aluminum circles : Belonging to the Al-Mn alloy family, its strength and hardness are superior to the 1000 series. It has excellent rust resistance, and after anodizing, its surface gloss is more durable and its color is more uniform. It is mostly used in mid-to-high-end cookware, pressure cookers and rice cooker inner pots.

Specifications of Anodized Aluminum Circles for Cookware

| Alloy | 1050, 1060, 1100, 3003 |

| Temper | O, H12, H14, H18, H24 |

| Diameter | 100mm - 1200mm (customizable) |

| Thickness | 0.4mm - 6.0mm |

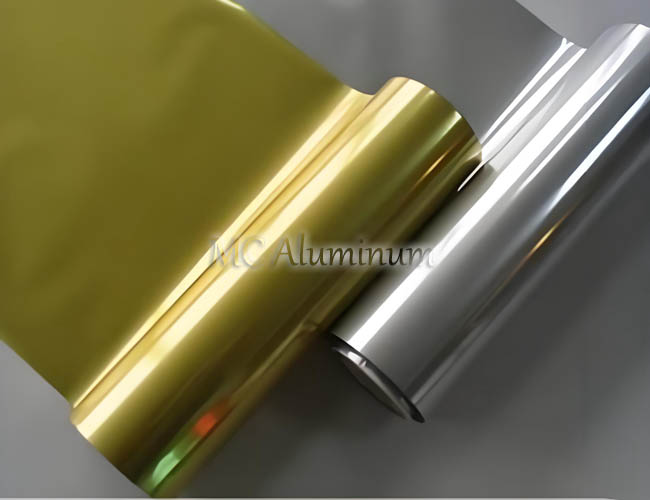

| Surface Treatment | Anodized, brushed, mirror, polished |

| Surface Color | Silver, gold, black, champagne, etc. |

| Tolerance | Thickness ±0.01mm, Diameter ±0.5mm |

| Applicable Processes | Spinning, stamping, drawing, deep drawing, anodizing |

| Samples | Available |

| Origin | Henan, China |

| Packaging | Wooden box or moisture-proof pallet |

| MOQ | 1-3 tons |

Performance Advantages of Anodized Aluminum Circles for Cookware

1. Exceptional hardness and wear resistance: The anodized layer makes the cookware surface highly resistant to scratches and wear.

2. Enhanced corrosion and chemical resistance: Effectively isolates the aluminum substrate from the environment, preventing corrosion from acidic or alkaline foods.

3. Health and safety assurance: The anodized layer is chemically stable and inert, preventing aluminum ion leaching, recognized as a safe processing method.

4. Maintains excellent thermal conductivity: Aluminum’s fast and even heat conduction is unaffected.

5. Easy cleaning and maintenance: Smooth anodized surface is simple and convenient to clean.

6. Ideal base for non-stick coatings: Provides perfect adhesion and durability for non-stick layers, such as PTFE (Teflon).

Comparison with Other Materials

1. Versus stainless steel: Significantly better heat conduction, avoiding localized overheating and energy waste.

2. Versus cast iron: Much lighter, faster preheating, and no complex seasoning or anti-rust maintenance required.

3. Versus ordinary aluminum: Solves issues of softness and reactivity, greatly extending service life.

4. Versus traditional non-stick coatings: Durability is enhanced; risk of coating peeling and food contamination is minimized.

Contact Us