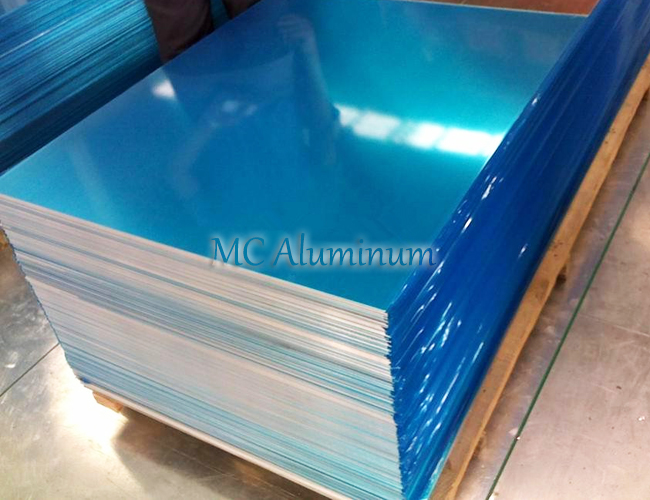

Aluminum plate for cans

Aluminum beverage cans first appeared in the late 1950s, and two-piece DWI cans were officially launched in the early 1960s. There are two materials for making cans: one is aluminum, and the other is tinplate. For the protection of the environment, the material of cans tends to be aluminum. Manufacturing techniques for aluminum cans have continued to improve over the decades, and aluminum cans have been significantly reduced in weight.

The alloys commonly used in aluminum alloy cans are 5052 aluminum plate, 3004 aluminum plate, and 3104 aluminum plate.

Advantages of aluminum alloy for cans:

1.Not easily broken, light in weight, and opaque.

2.Resistant to acid and alkali corrosion, durable, easy to recycle, economical and environmentally friendly.

3.Good strength, strong plasticity, high surface smoothness, very suitable for later processing, and low manufacturing cost.

4.Heat resistance, good conductivity, odorless and non-toxic, good printing effect.

Contact Us