5052 Aluminum Sheet For Fuel Tanks

Introduction: why 5052 for fuel tank fabrication

Fuel tanks and auxiliary fuel systems operate in environments that combine chemical exposure, moisture, vibration, and repeated thermal and mechanical loading. Material selection must therefore balance corrosion resistance, weldability, formability, and long-term dimensional stability. As a manufacturer of aluminum sheet and plate, we supply 5052 aluminum sheet for fuel tanks to OEMs and fabricators who require consistent properties across coils and lots, tight thickness tolerances, and reliable welding performance.

Alloy 5052 (Al-Mg) is widely used as an aluminum fuel tank sheet because it offers strong resistance to atmospheric and marine corrosion, good formability for tank shells and end caps, and stable performance in common fabrication processes such as bending, roll forming, and MIG or TIG welding. Compared with heat-treatable alloys, 5052 also avoids strength loss from localized overaging, which can be beneficial around weld zones when the design is governed by ductility and corrosion resistance.

Material overview: alloy system and typical tempers for tanks

5052 is a non-heat-treatable aluminum-magnesium alloy. Strength is achieved primarily through solid solution strengthening from magnesium and through work hardening, so temper selection is important for fabrication.

In fuel tank manufacturing, the most common choices are:

O (annealed): highest ductility for deep forming, complex end caps, or tight radii bends.

H32 / H34: strain-hardened and stabilized tempers that provide higher strength while maintaining good formability. 5052-H32 sheet is a frequent selection for general tank shells and structural features.

We manufacture 5052 sheet and plate in multiple tempers and thickness ranges, with stable grain structure and surface quality suitable for fabrication and finishing.

Key performance characteristics for fuel tank applications

Corrosion resistance: 5052 is often categorized as a marine grade alloy and performs well in humid, salt-laden, and industrial atmospheres. This helps minimize pitting and underfilm corrosion in external service.

Weldability: excellent compatibility with standard MIG/TIG processes. We supply material with controlled chemistry and cleanliness to support consistent weld quality.

Formability: suitable for bending, rolling, and moderate drawing. Temper selection enables optimization between strength and forming margin.

Fatigue and vibration behavior: good ductility helps accommodate cyclic loading, especially in welded assemblies when the design includes proper joint geometry.

For customers evaluating broader Aluminum Sheets options for tank and enclosure manufacturing, 5052 typically sits at the intersection of corrosion resistance, forming, and weldability.

Specifications and technical parameters

We produce 5052 aluminum sheet and plate to common international standards. Typical standards include ASTM B209 for aluminum sheet and plate and EN 485 for EN AW series products. Material can be supplied with mill test certificates and full traceability.

Typical supply specifications (factory capability)

| Item | Typical Range / Option | Notes |

|---|---|---|

| Alloy | 5052 / EN AW-5052 / AlMg2.5 | Non-heat-treatable Al-Mg alloy |

| Product form | Sheet, plate, coil | Cut-to-length available |

| Thickness | 0.5 mm to 25.0 mm | Wider range on request |

| Width | Up to 2200 mm (typical) | Depending on thickness and equipment |

| Length | Up to 12000 mm (plate/sheet) | Custom lengths supported |

| Temper | O, H32, H34, H112 | Other H tempers by agreement |

| Surface | Mill finish, one-side film, both-side film | Protection for fabrication |

| Standards | ASTM B209, EN 485 (as applicable) | Also customer specifications |

| Certification | MTC to EN 10204 3.1 | Chemistry, mechanicals, traceability |

| Flatness control | Leveling for cut sheets | Critical for tank panel fit-up |

Typical mechanical properties (reference values)

Actual values depend on thickness and applicable specification. We provide lot-specific test results on the mill test certificate.

| Property | 5052-O (Typical) | 5052-H32 (Typical) | Test standard basis |

|---|---|---|---|

| Tensile strength, Rm | 170 to 230 MPa | 210 to 260 MPa | ASTM/EN tensile test |

| Yield strength, Rp0.2 | 55 to 100 MPa | 130 to 180 MPa | ASTM/EN tensile test |

| Elongation (A50) | 18 to 30 pct | 8 to 16 pct | Thickness dependent |

| Density | 2.68 g/cm3 | 2.68 g/cm3 | Reference |

| Thermal conductivity | ~138 W/m.K | ~138 W/m.K | Reference |

Chemical composition (typical for alloy compliance)

| Element | Typical Limit (wt pct) | Role |

|---|---|---|

| Mg | 2.2 to 2.8 | Strength and corrosion performance |

| Cr | 0.15 to 0.35 | Grain structure stability |

| Fe | <= 0.40 | Impurity control |

| Si | <= 0.25 | Impurity control |

| Cu | <= 0.10 | Corrosion control |

| Mn | <= 0.10 | Impurity control |

| Zn | <= 0.10 | Impurity control |

| Ti | <= 0.10 | Grain refinement |

| Al | Balance | Base metal |

Manufacturing capabilities: rolling, finishing, and delivery formats

As a producing mill, we control the critical steps that affect fuel tank fabrication performance.

Rolling and processing route

Hot rolling and cold rolling to reach the requested thickness with consistent gauge control.

Intermediate annealing as required to maintain formability and avoid excessive work hardening.

Temper stabilization for H32/H34 to improve property stability in subsequent fabrication.

Tension leveling or roller leveling for cut sheets to improve flatness, which is important for tank panel alignment and weld seam consistency.

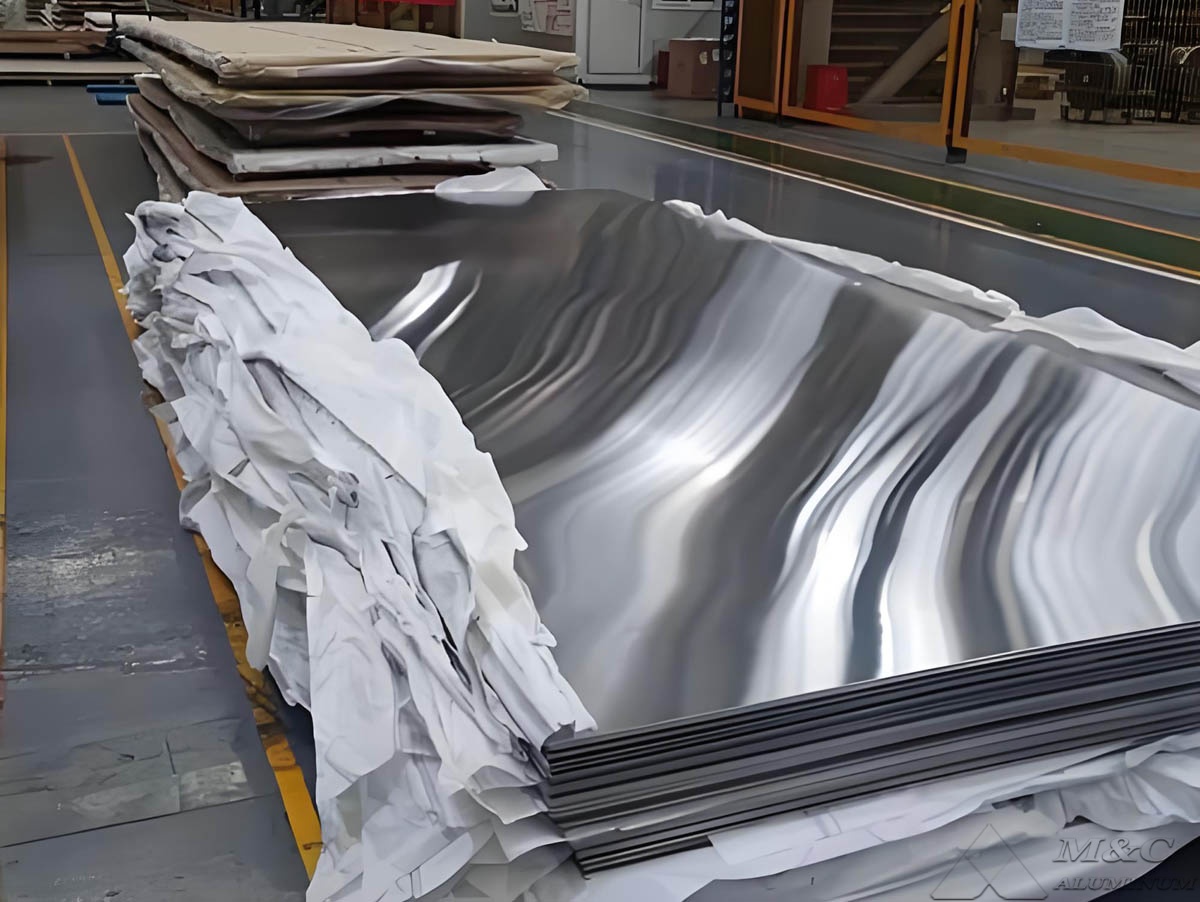

Surface quality and protection

Fuel tanks often require clean surfaces for welding and sealing. We supply:

Mill finish suitable for welding preparation.

Optional PVC film (one side or both sides) to reduce handling scratches.

Controlled surface inspection to minimize dents, roll marks beyond standard allowance, and edge defects.

Dimensional control for fabrication efficiency

We manufacture with attention to:

Thickness tolerance and profile consistency along length and width.

Edge trimming options (slit edges or mill edges) depending on customer cutting and welding practice.

Cut-to-length squareness and camber control for panels used in shell rolling and end closure fabrication.

Quality control, standards, and traceability

Fuel tank components must be consistent lot-to-lot to reduce welding variation and forming scrap. Our quality system focuses on process stability and documentation.

Incoming and melt control

Chemistry control aligned to ASTM/EN limits.

Melt and casting practice focused on cleanliness and inclusion control.

In-process inspection

Gauge measurement through rolling stages.

Flatness monitoring after leveling.

Surface inspection for defects that can interfere with sealing or welding.

Final inspection and documentation

Mechanical testing per applicable standard.

MTC issuance to EN 10204 3.1 upon request.

Coil and sheet identification to support full traceability from shipment back to melt.

Optional inspections for critical projects

Where required by the project, we can coordinate third-party inspection and additional documentation packages aligned with customer QA plans.

Customization options for fuel tank builders

Fuel tank designs differ by installation space, capacity, and compliance requirements. We routinely customize:

Temper selection: O for complex forming, H32/H34 for higher strength shells.

Thickness and width: optimized for weight and stiffness while maintaining weldable joint design.

Surface protection: film options based on fabrication flow.

Delivery format: coil for high-volume stamping or roll-forming, sheets/plate for CNC cutting and manual fabrication.

Kitted supply: cut-to-length panels for standard tank geometries to reduce customer cutting labor.

For customers standardizing on a proven grade, our 5052 Aluminum Sheet program supports long-term production with controlled properties and consistent documentation.

Application scenarios and target industries

5052 aluminum sheet and plate are commonly specified for:

Automotive and commercial vehicles: auxiliary tanks, fabrication of fuel cells, and protective enclosures.

Marine and offshore equipment: tanks and containment where external corrosion resistance is critical.

Industrial machinery: fuel and fluid tanks for generators, compressors, and construction equipment.

Transportation and specialty vehicles: buses, RVs, and service vehicles requiring lightweight tank solutions.

In many of these applications, customers select 5052 not only for corrosion performance, but also for predictable forming behavior and stable weld response in production.

Comparison with other aluminum alloys for fuel tanks

Material selection should account for environment, welding procedure, and forming method. Below is a practical comparison we use with customers during alloy selection.

5052 vs 5083

Strength: 5083 typically offers higher strength than 5052 in similar non-heat-treatable tempers.

Formability: 5052 generally provides easier forming for complex shapes at a given thickness.

Use case: choose 5083 when higher structural strength is needed; choose 5052 when fabrication flexibility and general corrosion resistance are primary.

5052 vs 5754

Both are Al-Mg alloys with good corrosion resistance and weldability.

5754 is often selected for automotive body and structural applications; 5052 remains a common and cost-effective choice for tanks and formed parts where stable supply and established welding procedures exist.

5052 vs 3003

3003 (Al-Mn) has very good formability but generally lower strength and different corrosion behavior compared with 5052.

For fuel tanks exposed to harsher environments and requiring stronger weldable joints, 5052 is frequently preferred.

5052 vs 6061

6061 is heat-treatable and can deliver higher strength, but forming can be less forgiving, and weld zones may require careful management of properties.

For tanks where corrosion resistance and consistent fabrication behavior are the main drivers, 5052 is often a better match.

Practical considerations for fabrication and welding

From a producer perspective, we recommend customers align material choice with process planning:

Welding: 5052 is a reliable weldable aluminum plate for tanks. Joint preparation, cleanliness, and suitable filler selection are essential for leak-tight welds.

Forming radius: select temper and thickness based on the minimum bend radius required by the design. O temper supports tighter radii; H32/H34 provides higher stiffness.

Surface preparation: remove protective film prior to welding and keep surfaces free from lubricants to avoid porosity.

Leak testing: material quality supports fabrication, but leak performance ultimately depends on welding procedure qualification and inspection methods.

Conclusion: stable mill supply, technical support, and long-term cooperation

As a manufacturer, our role is to provide 5052 aluminum sheet for fuel tanks with consistent chemistry, controlled mechanical properties, and reliable dimensional accuracy, supported by traceability and standard-compliant documentation. We work with OEMs and fabrication shops to match temper, thickness, and delivery format to the tank design and manufacturing route.

As a professional aluminum processing manufacturer, our products are of stable quality and exported to many countries and regions overseas. We provide samples and deliver within 7-45 days. For large orders of 8-5000 tons, we guarantee after-sales service. If you have any needs for aluminum plates, please contact us.

Contact Us