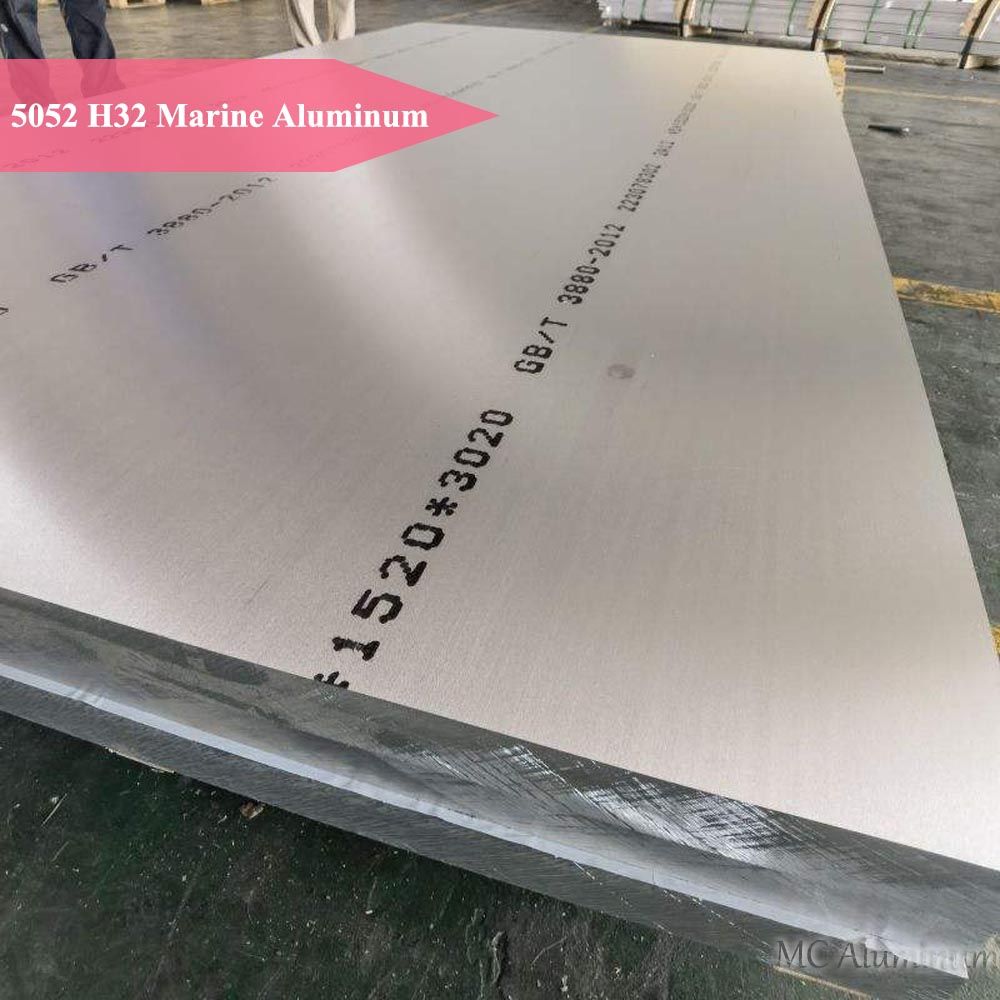

5052 H32 Aluminum Alloy Hull Plate

As the shipbuilding industry continues to advance toward lightweight construction and high performance, material selection plays a decisive role in determining vessel capability, efficiency, and service life.

All 5000 series aluminum alloys use magnesium as the primary alloying element, which significantly improves weldability-an essential requirement in marine fabrication.

Overview of 5052 H32 Aluminum Alloy

5052 marine aluminum alloy belongs to the Al-Mg alloy system, with magnesium as its principal alloying element. Although it is non-heat-treatable, it offers outstanding fatigue resistance and corrosion resistance, making it highly suitable for marine structures.

The designation "H32" indicates that the aluminum plate has undergone strain hardening and stabilization treatment. Compared with fully hardened tempers, H32 provides a well-balanced combination of moderate strength and excellent ductility, making it ideal for bending and welding during hull fabrication.

Core Advantages of 5052 H32 Marine Aluminum Alloy

Medium-to-High Strength

Tensile strength is significantly higher than that of pure aluminum, meeting the structural rigidity requirements of ship hulls.

Exceptional Marine Corrosion Resistance

Excellent resistance to seawater and marine atmospheric corrosion forms the foundation for its use as a hull material.

Outstanding Fatigue Strength

Capable of withstanding cyclic loads caused by continuous wave impact, ensuring long service life.

Excellent Formability

Easy to cut, bend, roll, and weld-particularly suitable for manufacturing complex hull geometries.

Product Technical Specifications

| Alloy | 5052 |

| Temper | H32 |

| Thickness | 3-50 mm |

| Width | 1000-2650 mm |

| Length | 1000-16000 mm |

| Surface Treatment | Anodizing / Coating / Anti-corrosion treatment |

| Packaging | Standard wooden pallet |

| Applications | Small and medium-sized vessels, speedboats, inland waterway ships |

| MOQ | 1-3 tons |

Mechanical Properties

| Tensile Strength | 215 MPa |

| Yield Strength | 130 MPa |

| Elongation | 12% |

| Hardness (HB) | 61 |

| Density | 2.7 g/cm³ |

Key Benefits of Using 5052 H32 Aluminum Alloy for Hull Construction

1. High Strength and Load-Bearing Capacity

Ship hulls must withstand internal pressure, vibration, and impact loads. The tensile and yield strength of 5052 H32 far exceed those of ordinary carbon steel, ensuring structural integrity and extended service life.

2. Superior Corrosion Resistance

Salt spray, humidity, and chemical corrosion are major threats in marine environments. The magnesium and chromium content of 5052 H32 promotes the formation of a dense aluminum oxide layer, significantly enhancing corrosion resistance.

3. Non-Magnetic Properties

An essential feature for specialized vessels such as mine countermeasure ships and scientific research vessels, where magnetic interference must be minimized.

4. Excellent Weldability

Compatible with mature MIG and TIG welding processes, producing welds with high strength and toughness for robust hull structures.

5. Excellent Formability

Hull construction involves complex curves and extensive bending operations. The H32 temper offers sufficient elongation to prevent cracking during large-radius forming of side and bottom plates.

6. Lightweight Performance

Compared with stainless steel, 5052 H32 has a density of only 2.7 g/cm³, reducing structural weight by approximately 50%. This directly contributes to higher vessel speed and lower fuel consumption.

7. Cost Efficiency

Although stainless steel may have a lower unit price, the lightweight benefits and longer service life of 5052 H32 result in a more competitive total lifecycle cost.

Marine Application Areas

1.High-Performance Workboats

Patrol vessels, pilot boats, and customs enforcement boats where lightweight construction enables higher cruising speeds.

2.Luxury Yachts and High-End Ferries

Aluminum alloy offers superior comfort, noise reduction, and maximized cabin space through weight savings and design flexibility.

3.Small Passenger Ferries and Water Buses

Designed for high-frequency operation on fixed routes, where low fuel consumption and minimal maintenance are critical to commercial success.

4.Specialized Vessels

Scientific research ships (non-magnetic), high-speed rescue boats, and lightweight auxiliary military vessels.

5.Superstructures

Even on steel-hulled vessels, using 5052 H32 for superstructures effectively lowers the center of gravity and improves overall stability.

Quality Control Requirements for 5052 H32 Marine Aluminum Plate

Chemical Composition Control

Magnesium (Mg) content must be maintained within 2.2%-2.8%. Insufficient Mg reduces strength, while excessive Mg negatively affects weldability.

Bending Performance

H32 plates must pass a 180° cold bending test without cracking, ensuring reliability during hull forming.

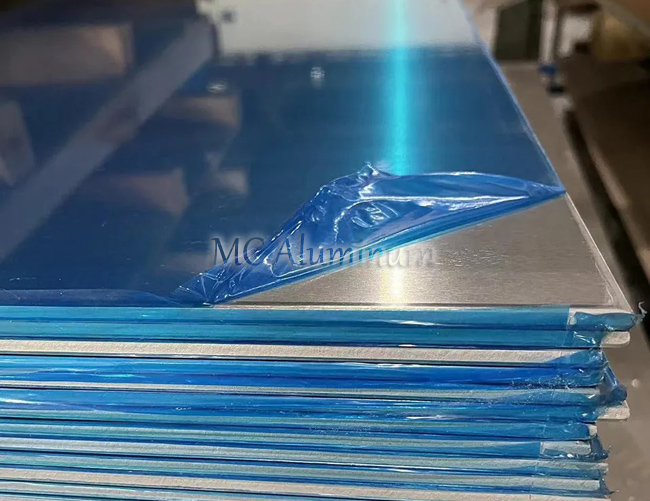

Flatness and Surface Quality

Marine plates require high flatness. Surface defects such as blisters, scratches, inclusions, or peeling are strictly prohibited, as they can initiate electrochemical corrosion.

Classification Society Certification

Mass production must comply with factory certification requirements of CCS (China Classification Society), DNV, or ABS, ensuring full quality traceability.

Comparison with Other Aluminum Alloys

Compared with 5083 Aluminum Alloy

5083 offers superior corrosion resistance but poorer weldability and higher cost.

Compared with 6061 Aluminum Alloy

6061 provides higher strength but is more prone to cracking and significantly more expensive, making it unsuitable for large-scale hull applications.

Contact Us