Aerospace Grade 2024 Aluminum Plate Sheet

What is 2024 Aluminum Plate?

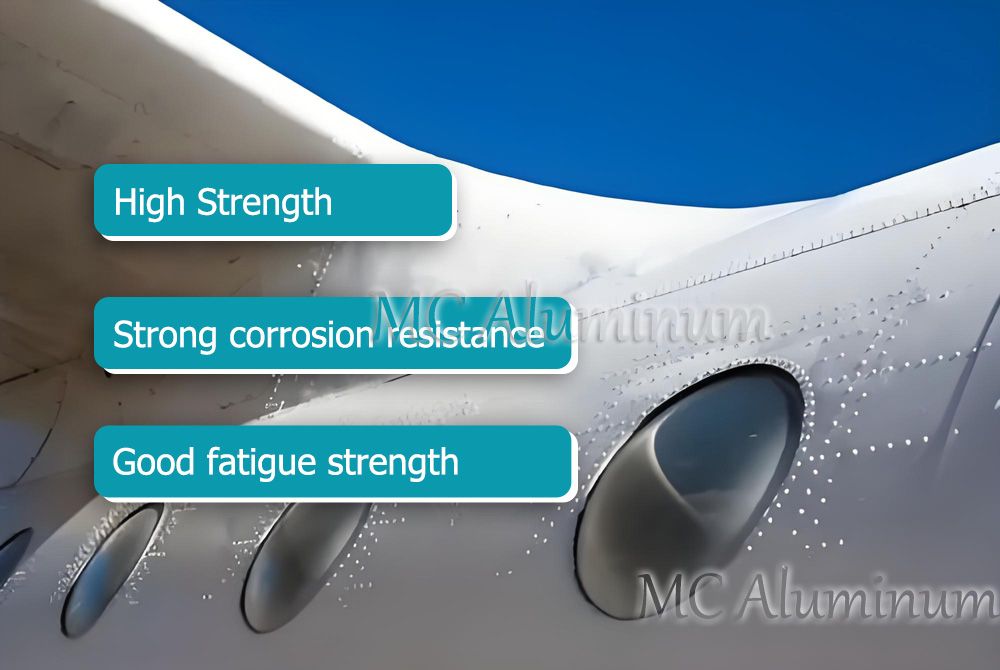

Among structural materials used in aircraft, 2024 aluminum alloy is regarded as a foundational material. As a heat-treatable alloy from the Al-Cu-Mg system, it is known for its high specific strength, excellent fatigue resistance, and good damage tolerance. These properties make it a staple material in aerospace structural components.

Key features include high strength, moderate heat resistance, and suitability for components operating below 150°C. Notably, 2024 aluminum exhibits higher strength than 7075 at temperatures above 125°C.

It offers good formability in hot, annealed, and freshly quenched states and responds well to heat treatment—though the process requires strict control. Corrosion resistance is relatively poor, but cladding with pure aluminum (Alclad) provides effective protection. While it is prone to cracking during welding, specialized techniques can overcome this. It is also ideal for riveting. Common applications include aircraft structures, rivets, truck wheels, propeller components, and other structural parts.

2024 Aluminum Plate Specifications

| Alloys | 2024, 2A12 |

| Tempers | O, T3, T4, T351, T851, T81, H112 |

| Thickness | 0.5mm - 300mm |

| Width | 500mm - 2650mm |

| Length | 500mm - 12,000mm |

| Surface Protection Film | Black & white film, blue film, transparent film (thickness: 50μm, 80μm) |

| Surface Finish Options | Bright, polished, brushed, satin, sandblasted, embossed, etched, and more |

Mechanical Properties of 2024 Aluminum Plate

| Property | 2024-O | 2024-T3 | 2024-T6 | 2024-T351 |

| Tensile Strength (MPa) | 100-200 | 320-480 | 310-480 | 330-460 |

| Shear Strength (MPa) | 130 | 290 | 290 | 290 |

| Fatigue Strength (MPa) | 90 | 140 | 140 | 140 |

| Elastic Modulus (GPa) | 71 | 71 | 71 | 71 |

| Brinell Hardness | 49 | 120 | 120 | 120 |

| Elongation at Break (%) | 15 | 15 | 16 | 13 |

Key Advantages of 2024 Aerospace Aluminum Plate

1. High Strength-to-Weight Ratio

With a density of approximately 2.78 g/cm³, 2024 aluminum provides exceptional strength while minimizing weight—ideal for aerospace structures where weight reduction is critical.

2. Excellent Heat Treatability

The alloy responds well to various tempers such as T3, T4, T351, T81, allowing tailoring of mechanical properties for specific manufacturing needs. Compatible with machining, stamping, stretching, and milling processes.

3. Good Rivetability and Limited Weldability

While its weldability is limited, friction stir welding (FSW) can be employed. In aerospace structures, riveting is commonly used with 2024 plates, ensuring high structural integrity and reliability.

4. Proven Performance and Standards Compliance

Compliant with multiple international standards including AMS, ASTM, MIL, GB, and more. These rigorous certifications make it suitable for global aerospace applications and manufacturing partnerships.

2024 aviation grade aluminum plate tempering state and its application:

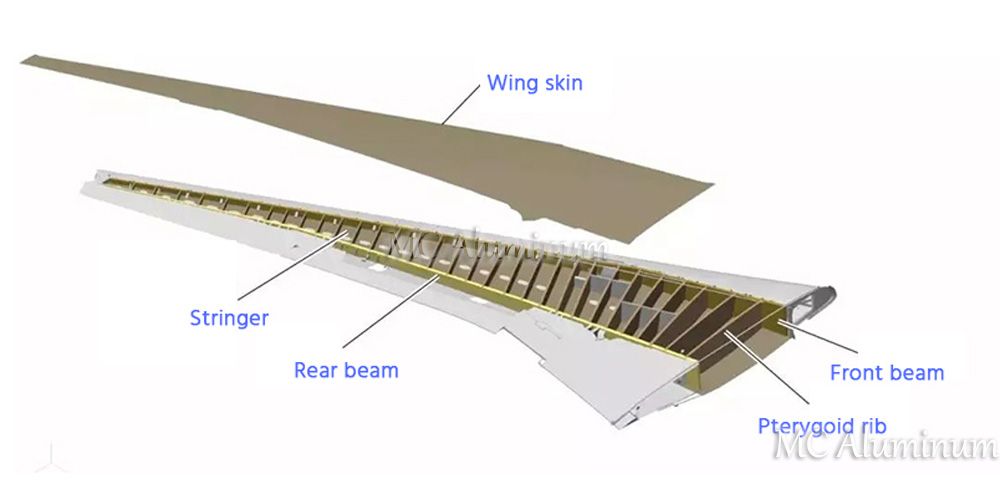

2024 T3 T4 aluminum plate

2024 T3 T4 aluminum plate is widely used in the aerospace industry for the manufacture of wing skins, webs, stiffeners and other structural components due to its high strength and fatigue resistance.

2024 T351 T851 aluminum plate

2024 T351 T851 aluminum plate is a special state of 2024 aluminum alloy, known for its high strength-to-weight ratio and good corrosion resistance. The following are their common uses.

2024 T351 aluminum plate

2024 T351 aluminum plate is known for its improved formability and weldability, and is ideal for applications that require complex shapes and high strength, such as aircraft skins, fuselages and other aerospace structures.

2024 T451 aluminum plate

2024 T451 aluminum plate has higher strength and stability than T3 and T4 tempered aluminum plates. It is often used for applications that require high strength, high fatigue resistance and good toughness, such as aerospace structural components.

2024 T851 Aluminum Plate

2024 T851 aluminum plate has higher strength and stability than T3 and T4 tempered aluminum plates. It is commonly used in aircraft parts and industrial machinery parts.

Addressing the Corrosion Challenge

One of 2024's limitations is its moderate corrosion resistance, especially in humid or salt-laden environments. Aerospace-grade 2024 aluminum plates typically use the following protective methods:

Alclad Cladding

The most common method. A thin layer of high-purity aluminum (typically 1xxx series, such as 1050 or 1230) is metallurgically bonded to the surface of the 2024 core. This sacrificial anodic layer significantly enhances corrosion resistance without compromising the core’s strength.

Anodizing

An electrochemical treatment that produces a dense, protective oxide layer on the surface, increasing both corrosion and wear resistance.

Coatings

In extreme environments, specialized protective coatings (e.g. primers, epoxy, or polyurethane) may be applied for enhanced durability and environmental protection.

Contact Us