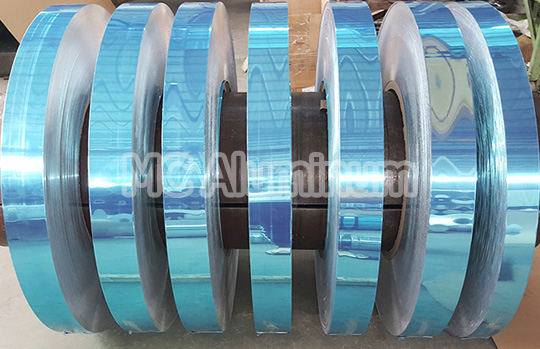

Anodized 5052 Aluminum Coil for Sale

In modern industry and architectural decoration, anodized 5052 aluminum coil is widely used in ships, transportation, electronic device housings, and high-end decorative projects due to its excellent corrosion resistance, workability, and attractive appearance.

MC Aluminum supplies 5052 aluminum coils in conditions including F, H112, O, H12, H14, H16, H18, H22, H24, H26, H36, etc., meeting various customer requirements. A wide range of sizes is available with thicknesses from 0.2mm to 150mm, widths from 1000mm to 2500mm, and lengths from 2000mm to 12000mm.

What is Anodized 5052 Aluminum Coil?

5052 aluminum alloy is part of the aluminum-magnesium series and features excellent formability, weldability, and fatigue strength. After undergoing anodizing treatment, a dense and stable oxide film forms on the surface of the aluminum coil. This anodized layer not only significantly improves corrosion resistance but also enhances the material's coloring capabilities and metallic texture.

Main characteristics after anodizing include:

Improved weather resistance, suitable for outdoor applications

Enhanced surface hardness and scratch resistance

More uniform, attractive appearance with strong metallic luster

Coloring capability for rich visual effects

Compatible with secondary processing such as screen printing and laser engraving

5052 Aluminum Coil Specifications:

| Alloy Tempers | 5052-H32, 5052-H34,etc |

| Thickness | 0.2mm – 6.0mm |

| Width | 20mm – 2000mm |

| Length | 100mm – 6000mm |

| Surface Treatment | Anodizing (transparent, black, gold, etc.) |

| Custom Colors | Supports RAL color chart, natural metal tone, or custom colors |

| Coil Weight | Typically 1–3 tons per coil |

| Surface Flatness | Ra ≤ 0.3μm |

Applications of Anodized 5052 Aluminum Coil:

Architectural Decoration: Curtain wall panels, façade trims, aluminum profile guards

Transportation: Subway interior panels, vehicle body cladding, container shells

Electronics Manufacturing: Laptop housings, speaker panels, LED back panels

Marine & Offshore: Cabin linings, anti-slip plates, offshore equipment shells

Home Appliances: Refrigerator side panels, microwave panels, air conditioner trim panels

How Much Does 5052 Aluminum Coil Cost per Ton?

The price depends on several factors including the current aluminum ingot market price, shipping costs, and processing fees. It also varies based on thickness and alloy specifications. For an accurate quote, please provide details such as alloy number, thickness, and length by email, and our professional customer service team will respond promptly.

How to Choose High-Quality Anodized 5052 Aluminum Coil:

1.Oxide Film Thickness & Uniformity:

The film thickness is key for corrosion and wear resistance. Decorative films are typically 5–15 microns, while functional films can exceed 25 microns. Uniform film ensures product consistency.

2.Surface Finish & Defect Control:

Inspect for scratches, color inconsistencies, spots, and uneven oxidation. High-quality coils should have a clean, smooth surface with consistent coloration.

3.Color Stability & Batch Consistency:

For color-sensitive applications, maintaining consistent shades across batches is critical.

4.Dimensional Precision:

Width, thickness, and flatness must meet specified tolerances to ensure proper use.

MC Aluminum is a large-scale manufacturer of 5052 aluminum coils and sheets. As a publicly listed company, it handles orders from 8 to 2000 tons, with delivery times ranging from 7 to 35 days and global shipping available. The company offers a full range of specifications, competitive pricing, and original factory warranties.

Contact Us