Flexible Packaging Aluminum Foil Thickness Range

What Is Flexible Packaging Aluminum Foil?

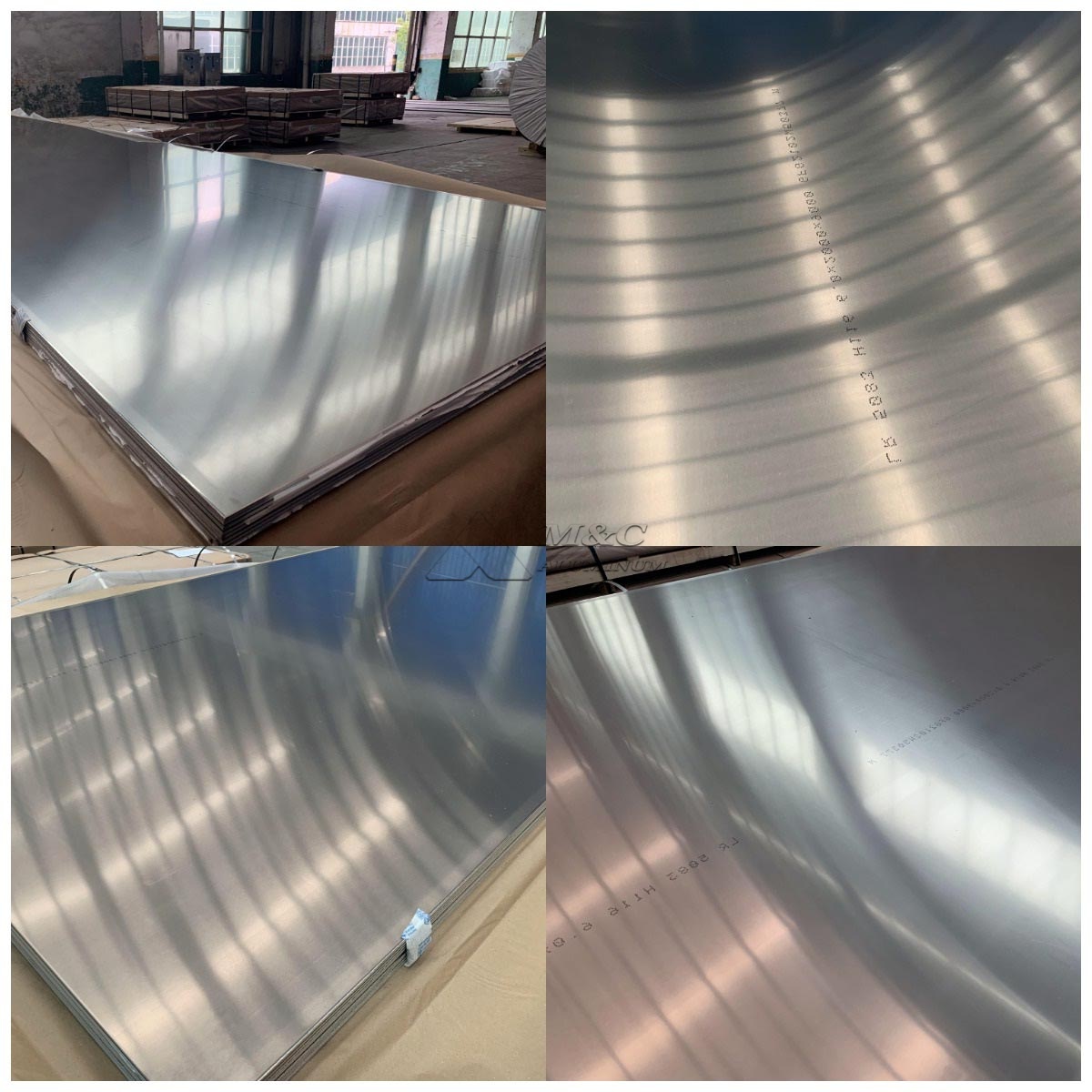

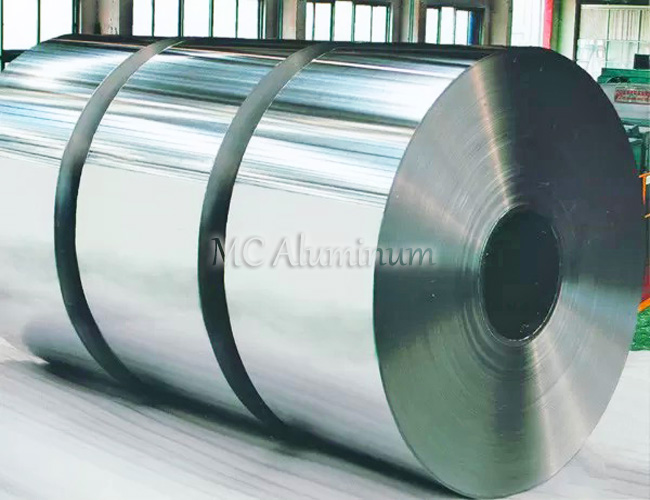

Flexible packaging aluminum foil has become one of the most essential materials in food, pharmaceutical, daily chemical, and industrial packaging. It is produced by rolling aluminum into thin sheets, typically supplied in soft temper (O temper) and designed for lamination with plastic films or paper.

The standard thickness range of flexible packaging foil is generally 9-18 μm, while the most commonly used thicknesses in practical applications are concentrated between 6-12 μm.

Flexible aluminum foil offers unmatched barrier performance, effectively blocking moisture, oxygen, and light. Its outstanding properties, such as moisture resistance, gas barrier capability, light shielding, and odor protection make it a preferred choice for high-performance packaging.

Common alloys include 1235, 8011, and 8079, which provide excellent ductility, low pinhole rate, and stable lamination and heat-sealing performance, fully meeting the requirements of high-speed packaging lines.

Technical Specifications of Flexible Packaging Foil

| Alloy | 1235, 8011, 8079 |

| Temper | O |

| Thickness | 0.006 mm - 0.20 mm |

| Width | 10 - 1600 mm |

| Length | Customized |

| Tensile Strength | Application-dependent, typically 150-250 MPa |

| Elongation | 2-5% |

| Heat Seal Strength | >10 N/15 mm |

| Barrier Properties | Excellent resistance to moisture, oxygen, and light |

| Temperature Resistance | -40°C to 200°C |

| Water Absorption | <0.5% |

Performance Advantages of Flexible Packaging Aluminum Foil

1.Superior Barrier Properties

Provides 100% barrier against light, oxygen, water vapor, bacteria, and odors.

2.Dead Fold Property

Unlike plastic films, aluminum foil has metal memory. Once folded, it retains its shape without spring-back.

3.Excellent Thermal Conductivity

Aluminum is an excellent heat conductor with a high melting point (approximately 600°C), allowing fast and efficient heat sealing during packaging.

4.High-Temperature Resistance

Withstands retort sterilization at 120°C or higher without deformation or release of harmful substances.

5.Safety and Hygiene

Aluminum is non-toxic, odorless, and hygienic, preventing bacterial or microbial growth.

6.Excellent Processability

Easily laminated with various plastic films and paper substrates.

7.Decorative Appearance

Natural silver metallic luster provides a premium and attractive visual effect.

Production Process

Coating:

Aluminum foil is coated with adhesives such as polyethylene or polyester to enable lamination.

Lamination:

The coated foil is bonded with other materials (plastic films or paper) to form multi-layer composite structures.

Printing:

Customized graphics and text are applied to meet branding and labeling requirements.

Cutting and Forming:

The laminated materials are slit and formed into specific sizes suitable for various packaging formats.

Application Areas

1.Food Packaging

Thickness: 0.03 - 0.05 mm

Advantages: Lightweight, excellent sealing performance, effective preservation.

2.Battery Packaging

Thickness: 0.06 - 0.10 mm

Requirements: High compressive strength to protect internal components from external forces.

3.Pharmaceutical Packaging

Thickness: 0.016 - 0.03 mm

Special Requirements: Must meet sterile standards and is typically laminated with plastic films.

Advantages Compared with Other Packaging Materials

1. Compared with Plastic Films

Plastic films offer good flexibility and heat-sealing performance but are semi-permeable, providing limited barriers against oxygen, moisture, and odors. Aluminum foil delivers superior barrier performance, significantly extending product shelf life.

2. Compared with Paper-Based Materials

Paper-based materials are sensitive to humidity and offer limited barrier and sealing performance. Aluminum foil is unaffected by environmental humidity and maintains stable sealing performance, making it more suitable for humid conditions and long-distance transportation.

3. Compared with High-Barrier Plastics

High-barrier plastics such as EVOH and PVDC perform well under ideal conditions but are sensitive to humidity and temperature fluctuations, which can degrade barrier performance. Aluminum foil provides absolute and stable barrier protection, ensuring long-term storage reliability.

Contact Us