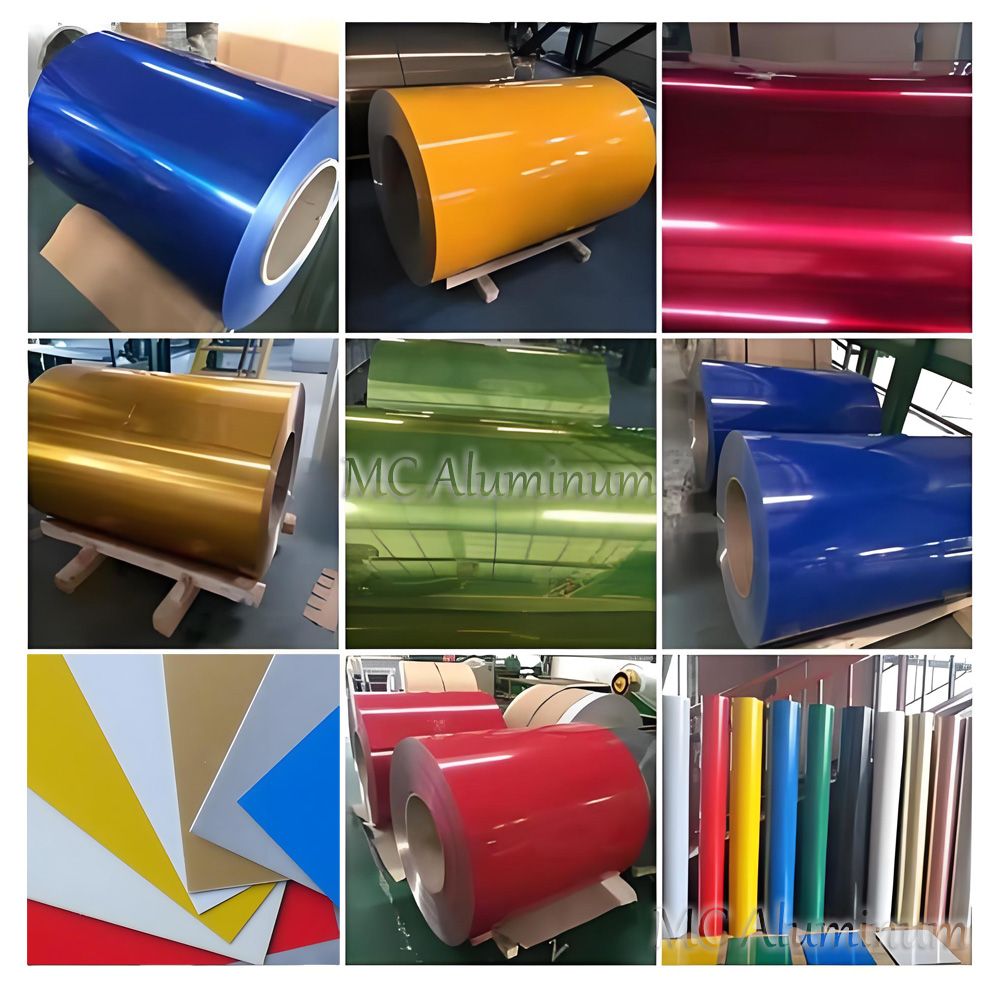

Color Coated Aluminum Sheet and Coil Manufacturer & Supplier

Color-coated aluminum is a material that undergoes a series of processes, including cleaning, chrome plating, roller coating, and baking, to create a surface coating. The PE/PVDF coating protects aluminum from UV radiation, corrosive gases, and microorganisms, extending its service life. Due to its excellent flatness, decorative properties, weather resistance, mechanization, and environmental friendliness, it is widely used in the construction, decoration, and other industries.

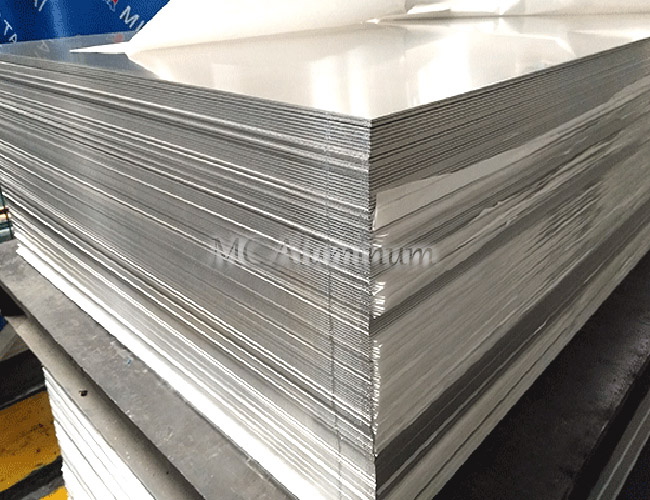

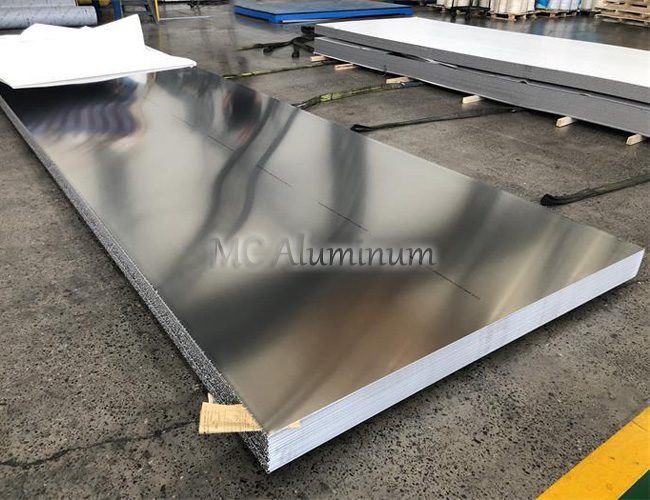

It is available in sheet or coil form. Color-coated aluminum sheet coil is a semi-finished roll material produced continuously in a factory, while color-coated aluminum sheet is a finished flat sheet produced by slitting (i.e., cutting) the color-coated aluminum coil into sheets according to the required size.

Coating Types

PE (Polyester Coating): Offers bright colors, strong adhesion, and moderate weather resistance, making it suitable for indoor applications.

PVDF (Fluorocarbon Coating): Excellent weather and UV resistance, with a service life of over 20 years, making it suitable for exterior curtain walls, roofing, and other applications.

Epoxy Coating: Offers outstanding chemical resistance and is often used for the inner layer of food packaging.

Common Alloy Materials

Common grades of color-coated aluminum sheet coil include 1050, 1100 (pure aluminum), 3003 (aluminum-manganese alloy with excellent rust resistance), 3004, 3105, and 5052 (aluminum-magnesium alloy with high strength). The choice depends on the requirements for strength, formability, and corrosion resistance.

1050 Color-Coated Aluminum Coil

1050 aluminum belongs to the 1 series pure aluminum, featuring high purity, low strength, and excellent tensile properties. It is widely used in applications such as bottle caps, closures, cans, and cosmetic lids.

1100 Color-Coated Aluminum Coil

1060 color-coated aluminum belongs to the pure aluminum series, featuring good ductility, excellent formability, high corrosion resistance, long service life, and low cost. However, its strength and stiffness are lower than those of 3 and 5 series aluminum. Its applications are similar to those of 1050 color-coated aluminum sheet.

3003 Color-Coated Aluminum Coil

3003 aluminum alloy is less expensive than 3105 and offers moderate strength, atmospheric corrosion resistance, good weldability, and good cold formability. Compared to 1000 series alloys, it possesses superior mechanical properties, especially at high temperatures. Therefore, it is widely used in roofing and siding, ceilings, corrugated panels, and other applications.

3004 Color-Coated Aluminum Coil

3004 color-coated aluminum strip has higher strength than 3003, offering excellent formability and corrosion resistance. It is the most widely used color aluminum product, widely used in public buildings such as airports, stations, and stadiums.

3105 Color-Coated Aluminum Coil

3105 coated aluminum strip offers excellent rust resistance, good electrical conductivity, high ductility during annealing and tempering, good ductility during semi-cold hardening, low ductility during cold hardening, excellent corrosion resistance, and excellent weldability.

5052 Color-Coated Aluminum Coil

5052 aluminum alloy belongs to the 5-series aluminum alloy, also known as aluminum-magnesium alloy. Currently, in the construction industry, 5052 color-coated aluminum sheet can be made into colored aluminum tiles through pressing and bending processes, and is widely used in interior and exterior decoration.

Features of Color-Coated Aluminum Products

1. Highly Decorative: Rich colors and a uniform coating can be used to simulate wood and stone grains, creating an aesthetically pleasing finish.

2. Weather-Resistant and Corrosion-Resistant: The coating system effectively isolates the aluminum from external contact, ensuring a long service life.

3. Excellent Processability: Easy to cut, bend, stamp, and curl, and resists cracking and paint peeling.

4. Lightweight: Lightweight, easy to transport and install, and reduces building loads.

5. Anti-fingerprint, anti-static, and anti-scratch: A fluorocarbon or polyester paint coating imparts antibacterial, corrosion-resistant, fingerprint-resistant, anti-static, and scratch-resistant properties to the aluminum sheet.

6. Environmentally Friendly: The aluminum substrate is 100% recyclable.

Color-Coated Aluminum Coil Product Information:

| Color-Coated Aluminum Coil Product Information: | 1xxx: 1050, 1050A, 1100 3xxx: 3003, 3105 5xxx: 5005, 5052 |

| Tempers | H12, H14, H16, H18, H22, H24, H32, H34, etc. |

| Thickness | 0.25 - 1.8 mm |

| Width | 500 - 1,550 mm |

| Length | Coil or cut-to-length 2,000 - 4,000 mm |

| Coatings | PE, PVDF |

| Coating thickness | Front ≥18 μm (PE), ≥25 μm (PVDF); Back 8–10 μm (PE or epoxy) |

| Colors | RAL standard or customized sample-approved colors |

| Surface protection | PE/PVC protective film (if required) |

| Gloss | 20%-80%, customized upon request |

| Coil ID | 405 mm, 505 mm, 605 mm |

| MOQ | 1-3 tons |

Applications

1. Construction (Main Market):

Curtain walls and ceilings (PVDF coating preferred)

Roofing systems (stadiums, airports; often profiled on-site from coils)

Rolling shutters, garage doors

Insulation composite panels (sandwich panels with PU or rock wool core)

2. Home Appliances:

Air conditioner panels

Washing machine covers

Water heater shells

Range hoods, etc.

3. Transportation:

Interior panels of high-speed trains and subways

Ship compartments

Automotive parts

4. Furniture & Home Décor:

Aluminum furniture

Security doors

Decorative wall panels

FAQ

Q1: What types of coatings are used for prepainted aluminum coil?

A1: The most common are PVDF (superior weather resistance) and PE (bright colors, good flexibility).

Q2: What thicknesses are available?

A2: Typically 0.25-1.8 mm, customizable upon request.

Q3: How is the coating applied?

A3: The coil is cleaned, pretreated, and continuously coated using roller-coating technology, ensuring uniform adhesion and long-lasting finish.

Q4: What’s the difference between PE and PVDF coatings?

A4: PE coatings offer vivid colors and flexibility for indoor decoration, while PVDF coatings provide superior UV/weather resistance for outdoor cladding.

Q5: What are the benefits of using prepainted aluminum coil?

A5: It combines durability, lightweight, corrosion resistance, and aesthetic appeal, making it ideal for construction and industrial applications.

Contact Us