Comparison of Marine-Grade 5052 Aluminum Alloy and 5083 Aluminum Alloy

In the shipbuilding industry, lightweight design, corrosion resistance, and high strength are indispensable core requirements. Thanks to their excellent overall performance, 5 series marine aluminum alloys have become one of the mainstream materials in modern ship construction. Among them, 5052 and 5083 are the two most commonly used marine-grade aluminum alloys, often presenting buyers with a difficult choice.

Introduction to 5xxx Series Marine Aluminum Alloys

5052 Marine Aluminum

5052 aluminum alloy is often referred to as the "all-rounder" of the shipbuilding industry. It is a non-heat-treatable alloy containing approximately 2.5% magnesium with a small amount of chromium.

Excellent formability:

Its greatest advantage lies in its ductility. It can be bent and cold-formed into complex shapes without cracking, making it a preferred material for manufacturing intricate marine components.

Fatigue strength:

The fatigue strength of 5052 aluminum alloy is higher than that of many other aluminum alloys, which is critical for parts subjected to continuous vibration, such as fuel tanks and internal housings.

Corrosion resistance:

It offers excellent resistance to marine and freshwater environments. Although its long-term seawater corrosion resistance is slightly inferior to that of 5083, it is more than sufficient for above-waterline structures and small inland or lake vessels.

Common tempers:

Typically supplied in H32 (strain-hardened and stabilized) or O (annealed) temper to balance hardness and workability.

5083 Marine-Grade Aluminum

5083 aluminum alloy is a specialist for "heavy-duty" applications. With a magnesium content close to 5%, it is specifically designed for high-stress environments and long-term exposure to seawater.

Exceptional corrosion resistance:

5083 is engineered to withstand the aggressive corrosive nature of seawater. It resists intergranular corrosion, which can occur in the heat-affected zones of welds.

Outstanding weldability:

One of its most notable features is its ability to retain excellent mechanical strength after welding. This makes it the preferred material for large ship hull construction, where structural integrity is critical.

Low-temperature performance:

It performs exceptionally well at low temperatures and is therefore also used in the hull structures of liquefied natural gas (LNG) carriers.

Specific tempers (H116 / H321):

For marine applications, 5083 plates are strictly produced in H116 or H321 temper. These special treatments prevent exfoliation corrosion, ensuring long-term durability even after decades of immersion in marine environments.

Marine-Grade Aluminum: 5052 vs. 5083

1. Chemical Composition

5052 Aluminum Alloy:

Magnesium content of approximately 2.2%-2.8%. It is a medium-strength Al-Mg alloy that balances strength, formability, and corrosion resistance.

5083 Aluminum Alloy:

Magnesium content increased to 4.0%-4.9%, with additional manganese for strengthening. It is classified as a high-strength marine aluminum alloy.

The near doubling of magnesium content gives 5083 a significant advantage in strength and hardness over 5052, making it one of the strongest non-heat-treatable aluminum alloys.

2. Mechanical Properties

| Property | 5052 Aluminum Alloy | 5083 Aluminum Alloy |

| Tensile Strength | Medium | High |

| Yield Strength | Medium | Significantly Higher |

| Elongation | Good | Good |

| Fatigue Resistance | Good | Excellent |

5052 is more suitable for structures requiring high formability and surface quality with relatively low load demands.

5083 is better suited for primary hull structures, load-bearing components, and high-stress environments.

3. Corrosion Resistance

5052 Aluminum Alloy:

Exhibits good resistance to seawater, atmospheric exposure, and various industrial environments, making it ideal for components with long-term exposure but lower structural stress.

5083 Aluminum Alloy:

Demonstrates superior stability in high salt spray, high humidity, and splash-zone environments, and is widely recognized as a standard marine structural aluminum alloy.

From a long-term service reliability perspective, 5083 clearly offers greater advantages in harsh marine environments.

4. Processing Performance

5052 has lower tensile strength but a low work-hardening rate and excellent ductility, making it easier to form and process.

5083, due to its higher strength, is more prone to cracking during bending and places greater demands on forming equipment.

5. Application Areas

5052 Aluminum Alloy:

Inland waterway vessels, fishing boats, and superstructures of ships.

5083 Aluminum Alloy:

Ocean-going vessels, yachts, and underwater or highly stressed sections of ships.

6. Cost Effectiveness

Compared with 5083, 5052 is more cost-effective, making it the preferred choice for budget-sensitive projects.

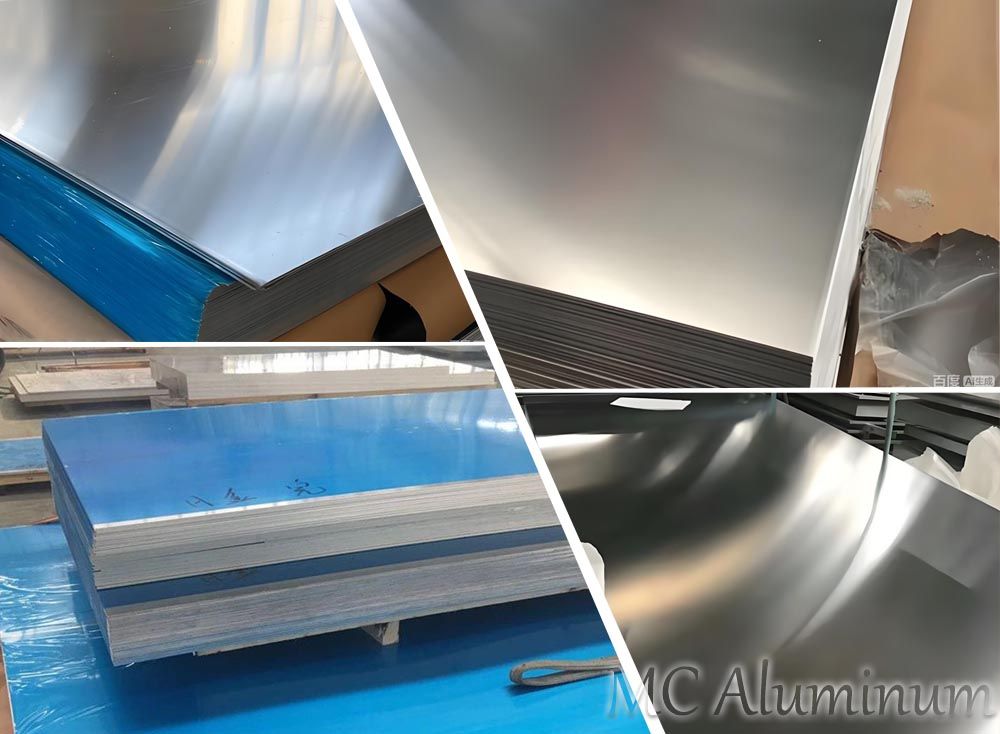

About MC Aluminum

As a professional aluminum plate manufacturer, MC Aluminum supplies marine-grade aluminum plates certified by major classification societies such as CCS, DNV, LR, and BV, fully meeting customer requirements. We produce 5xxx series (5052, 5083, 5059) and 6xxx series (6061, 6082) marine aluminum plates. With stable quality, factory-direct pricing, sample availability, and exports to more than 40 countries and regions worldwide, we provide reliable aluminum solutions for global marine applications.

Contact Us