- sales@alummc.com

- Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

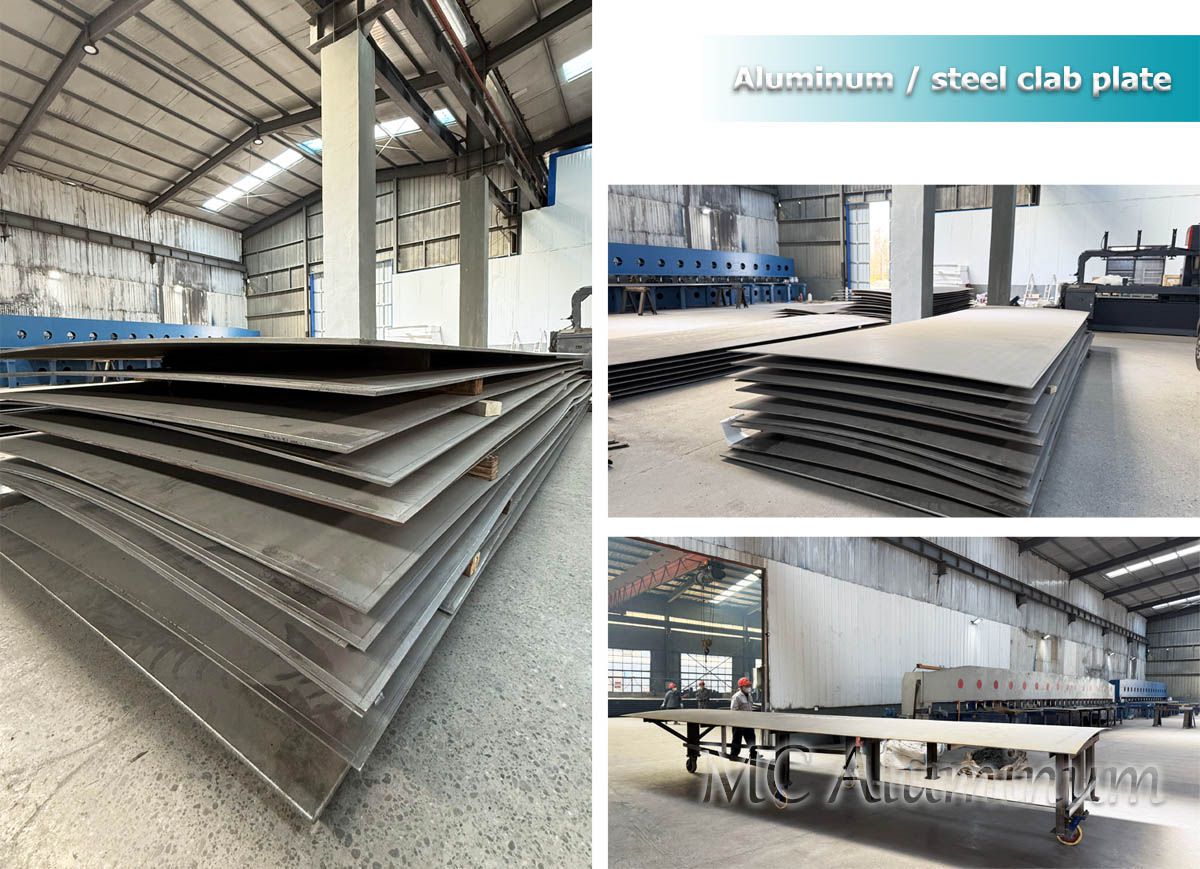

Aluminum-steel clad plate, also known as aluminum-clad steel, is a type of metal composite material with unique performance characteristics. Steel is known for its high hardness, brittleness, and high melting point, while aluminum offers excellent electrical conductivity, thermal conductivity, good corrosion resistance, and low density. When these two metals are combined, they fully leverage the superior properties of both materials.

Aluminum-steel composite plates are made by bonding aluminum plates with steel plates using processes such as explosive welding, hot rolling, or a combination of explosive welding and rolling. This process creates a composite material where aluminum and steel are bonded at the interface using different physical, chemical, and mechanical properties. The result is a material that combines the high hardness and wear resistance of specialty metals with the structural properties of general steel.

Aluminum Layer:

Made from high-purity aluminum alloys such as 1060, 3003, 5083, etc.

Thickness: Typically ranges from 0.1 to 3.0 mm.

Provides corrosion resistance and surface decoration properties.

Steel Layer:

Made from low-carbon steel (such as Q235B), pressure vessel steel (Q245R), and others.

Thickness: Typically ranges from 0.5 to 6.0 mm.

Bears the main structural load.

Composite Interface:

Metallurgical bonding achieved through hot rolling or explosive welding.

In some cases, high-polymer adhesives may be used to enhance interlayer bonding strength.

| Grades | Aluminum-Steel |

| Main Materials | Aluminum: 1A97, 1A93, 1A90, 1A85, 1070, 1060, 5083 Steel: Q235B, CCSB, Q245R, Q345R, 15CrMoR, 16Mn, 20MnMo, 15CrMo, 109MnNiDR, 16MnD, 09MnNiD |

| Plate Thickness | 1-6 mm (customizable) |

| Aluminum Thickness | 0.3-3 mm |

| Steel Thickness | 0.5-3mm |

| Width | 600-1600 mm |

| Length | 1000-16000mm |

| Technology | Explosive Welding |

| Surface Treatment | Brushed, anodized, painted, or polished aluminum surface. |

| Specifications | 1~14/6~80x <1000x<4000 |

| Standards | GB/T 8546-2007 |

| Applications | Electrolytic aluminum, transition joints, naval vessels, aerospace, instrumentation, cryogenic engineering, etc. |

1. High Strength:

Offers robust structural performance, making it suitable for harsh environments like marine and industrial applications.

2. Excellent Electrical and Thermal Conductivity:

Combines the conductivity of aluminum with the strength of steel.

3. Good Toughness:

Suitable for dynamic and high-stress environments.

4. Easy Maintenance:

The combination of aluminum and steel provides a durable material with low maintenance costs and a long lifespan.

5. Cost-Effective Material:

Reduces overall material costs while maintaining high performance.

6. Solves Dissimilar Metal Welding Issues:

Provides a solution to the common issue of welding dissimilar metals by utilizing advanced bonding techniques.

1.Transportation Industry

Automotive: Used in vehicle body structures, heat exchangers, etc., reducing weight and improving fuel efficiency.

Shipbuilding: Used in ship hulls, enhancing corrosion resistance and reducing weight.

Aerospace: Used in aircraft fuselages, wings, etc., meeting the requirements for lightweight and high-strength materials.

2.Construction Industry

Curtain Wall Systems: Used in the exterior wall decoration of high-rise buildings, providing aesthetic and durable solutions.

Roof Structures: Used in large building roofs, reducing weight and improving wind resistance.

3.Energy Sector

Heat Exchangers: Used in power plants, chemical equipment, etc., improving heat transfer efficiency.

Condensers: Used in refrigeration systems, offering high-performance heat exchange capabilities.

4.Electronics Industry

Heat Sinks: Used in electronic devices to enhance heat dissipation, improving stability and lifespan.

Electromagnetic Shielding: Used in sensitive electronic devices to prevent electromagnetic interference.

5.Other Fields

Home Appliances: Used in refrigerators, air conditioners, etc., improving energy efficiency and durability.

Industrial Equipment: Used in pressure vessels, pipelines, etc., providing corrosion resistance and high-pressure durability.