Functions of Gold Hydrophilic Aluminum Foil

What Is Gold Hydrophilic Aluminum Foil?

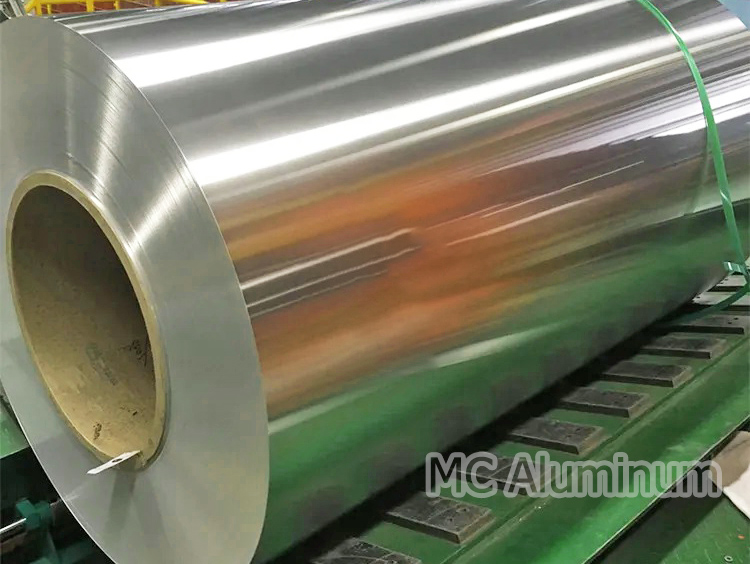

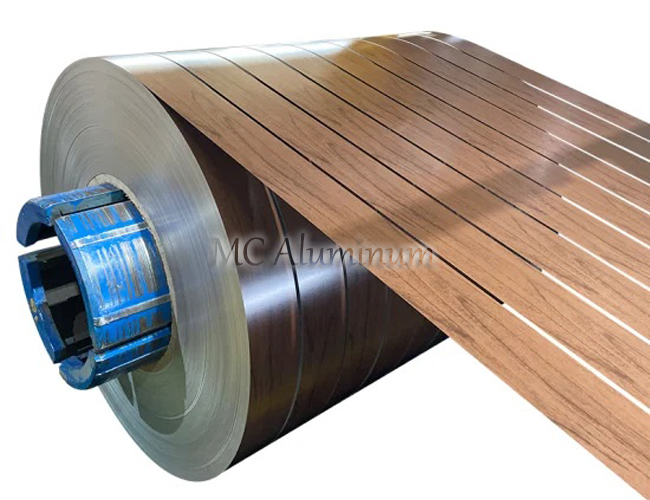

Gold hydrophilic aluminum foil is a type of metal material in which a hydrophilic coating is applied to the surface of an aluminum foil substrate, combined with gold paint or a gold-colored layer. The substrate is usually a common alloy used in air conditioning and heat exchangers, such as 3102 aluminum foil, 8011 aluminum foil, and 1100 aluminum foil.

The hydrophilic coating allows condensed water to quickly spread into a thin film and drain smoothly, while the gold coating provides both visual appeal and additional surface protection.

Basic Functions of Hydrophilic Aluminum Foil

Hydrophilic aluminum foil is commonly available in gold, blue, or green, and its core function is to solve condensation management issues that occur with traditional bare aluminum foil in cooling applications.

1. Efficient Condensate Management

The hydrophilic coating gives the aluminum surface strong water affinity. Condensate does not form spherical droplets as on ordinary aluminum foil but quickly spreads into a uniform thin water film. This film flows rapidly along the fins, avoiding the "water bridge" effect.

2. Improved Heat Exchange Efficiency

Smooth water drainage prevents fin channels from being blocked by droplets, ensuring unrestricted airflow and maximizing the effective heat transfer area, significantly improving the energy efficiency ratio (EER/COP) of air-conditioning systems.

3. Extended Service Life

Hydrophilic coatings are typically composite functional coatings that isolate the aluminum substrate from acidic substances, salt spray, and industrial pollutants in the air. This greatly enhances corrosion resistance, especially in humid and coastal environments.

4. Noise Reduction

Water drains as a thin film rather than dropping as droplets, reducing impact noise and enhancing user comfort.

Functions of the Gold Hydrophilic Coating

1. Aesthetic Appeal: Enhances the visual quality of visible components such as unit housings and decorative panels.

2. Brand Identification: Different colors can distinguish product models or production batches.

3. Optical Properties: Certain formulas adjust reflectivity, influencing local thermal radiation and visual appearance.

4. Oxidation Resistance: Gold coatings typically provide excellent UV and oxidation resistance, maintaining stable fin performance outdoors.

5. Enhanced Corrosion Protection: High-end epoxy or fluoropolymer coatings make gold hydrophilic foil more suitable for extreme environments, such as high-salt coastal areas or industrial environments with corrosive gases, compared to blue or green coatings.

Applications of Gold Hydrophilic Aluminum Foil

Evaporator and condenser fins in residential and commercial air conditioners

Automotive air-conditioning heat exchangers and micro-coolers

Cold chain equipment, refrigerated vehicle doors, internal panels of refrigeration systems

Heat pumps and HVAC system heat exchangers

Interior or non-structural exterior panels of marine/coastal equipment where color differentiation is needed

Product Parameters of Gold Hydrophilic Aluminum Foil

| Alloy | 3102, 8011, 1100, 5052 |

| Temper | O, H22, H24, H26 |

| Thickness | 0.08-0.50 mm |

| Width | 20-1600 mm |

| Length | 1000-16,000 mm |

| Coil inner diameter | 75 / 150 / 300 mm |

| Coil weight | 50-500 kg/coil |

| Tensile strength (MPa) | 80-180 |

| Elongation (%) | -20 |

| Hardness (HV) | 20-45 |

| MOQ | 1-3 tons |

Surface Coating Parameters:

| Coating type | Hydrophilic coating (transparent / blue / gold) |

| Coating thickness | 2-15 μm |

| Contact angle (hydrophilicity) | ≤ 30° |

| Color | Gold (customizable RAL/Pantone) |

| Salt spray resistance | 200-1000 hours |

| Damp heat resistance | 240-500 hours |

FAQ

Q1: Is there a difference between gold and blue hydrophilic aluminum foil?

A1: There is no fundamental difference in hydrophilicity and basic efficiency. Some suppliers may equip gold coatings with higher-grade anti-corrosion additives or thicker layers, giving superior corrosion and antibacterial performance compared to standard blue or green foils, targeting high-end markets.

Q2: Will the gold coating affect air-conditioning cooling performance?

A2: No. The coating is very thin (typically 1-3 μm), so its thermal resistance is negligible. In fact, the gold coating’s efficient water drainage mechanism can enhance overall cooling efficiency.

Q3: Is gold hydrophilic aluminum foil seawater resistant?

A3: If the substrate is 8011 or 3102 and the coating contains salt-spray-resistant components, it has good seawater resistance. For prolonged exposure to strong coastal salt spray, an additional protective layer (e.g., PVDF fluorocarbon) or regular maintenance is recommended.

Q4: How is hydrophilicity tested?

A4: Common methods include measuring the static contact angle-smaller angles indicate higher hydrophilicity, or observing whether water spreads into a thin film and drains within a set time.

Contact Us