What is Aircraft-Grade Aluminum?

Aluminum has been used in the aerospace industry since the late 19th century. It was already present during the Wright brothers’ first powered flight in 1903 and has continued to play a critical role in aviation and space missions, including the Apollo spacecraft, space shuttles, and the International Space Station. Due to its specific metallurgical properties and precision tolerances, various aircraft aluminum alloys are widely used in the construction of aircraft.

What is Aircraft-Grade Aluminum?

Aircraft-grade aluminum refers to a category of aluminum alloys specifically designed and optimized for the aerospace industry. Common grades include 2024, 6061, 7050, and 7075. These alloys are engineered through unique formulations and manufacturing processes to achieve performance characteristics far beyond those of standard aluminum, making them essential for building aircraft, spacecraft, and components such as fuselages, wing skins, frames, landing gear parts, and rocket fuel tanks.

Common Aircraft Aluminum Alloys

✦ 2024-T3

One of the most widely used high-strength aluminum alloys in the aviation industry. While its corrosion resistance is lower than 6061, it has excellent fatigue resistance. It's commonly used in the fuselages, wing skins, aircraft structures, and fairings. Its shiny finish also makes it ideal for repairs and restoration.

✦ 7075-T6

7075-T6 is primarily used to reinforce aircraft structures. Composed of aluminum alloyed with copper, magnesium, and zinc, it offers exceptional strength. However, due to its copper content, it is harder to weld (though not impossible). After anodizing, it has a smooth surface finish and outstanding machinability.

Other Specialized Grades:

✦ 6061-T6

Known for high corrosion resistance and excellent surface finish. It’s easy to weld and has strength nearly equivalent to low-carbon steel. It’s often used for landing pads, truck frames, and structural parts. It is highly versatile and easy to fabricate.

✦ 5052-H32

A non-heat-treatable aluminum alloy with high fatigue strength and excellent corrosion resistance, particularly in marine environments. Though not a structural alloy, it is ideal for manufacturing fuel tanks due to its workability.

✦ 3003-H14

Made from a mix of pure aluminum and manganese, this alloy is known for its good formability. It cannot be heat-treated but is suitable for deep drawing, welding, spinning, or brazing. Commonly used in aircraft fairings and baffles.

Comparison Between 2024 and 7075 Aircraft Aluminum

| Property | 2024 | 7075 |

| Ultimate Tensile Strength | 469 MPa / 68,000 psi | 572 MPa / 83,000 psi |

| Major Elements | Al, Cu, Mn, Mg | Al, Zn, Mg, Cu |

| Formability / Workability | Good | Poor |

| Weldability | Poor | Poor |

| Machinability | Fair | Fair |

| Corrosion Resistance | Poor | Average |

| Heat-Treatable | Yes | Yes |

| Strength-to-Weight Ratio | High | High |

| Fatigue Resistance | High | Good |

| Aircraft Applications | Wing & fuselage structures, truck wheels, hardware | Wing spars, highly-stressed parts, missile components |

Key Characteristics of Aircraft-Grade Aluminum

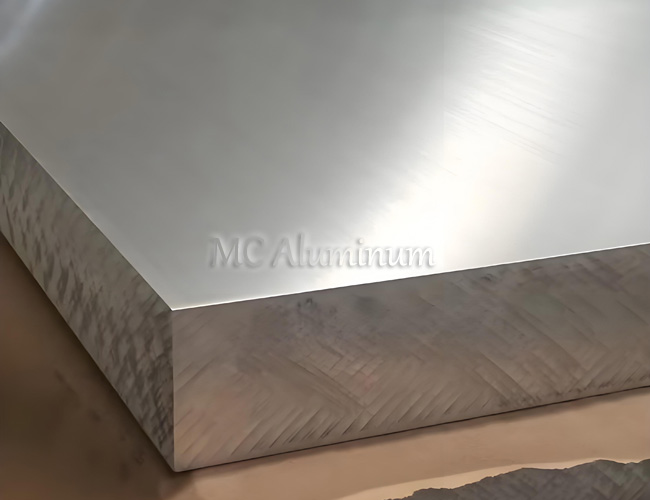

1.High Strength-to-Weight Ratio

Aircraft aluminum is strong yet lightweight, with only one-third the density of steel and up to 70% of its strength. These properties make it ideal for components in aerospace and automotive applications.

2.Corrosion Resistance

Most aircraft-grade alloys offer excellent resistance to corrosion, extending service life and maintaining surface finish. The degree of resistance varies by alloy.

3.Good Toughness

Aluminum alloys maintain ductility under impact loading (e.g., bird strikes) and low temperatures, preventing brittle failure.

4.Electrical Conductivity

Aluminum has higher conductivity than materials like stainless steel, making it a preferred material for electrical and electronic components in aircraft.

5.Excellent Surface Finish

Due to visibility of many parts, aluminum’s surface can be easily enhanced through anodizing, coloring, or painting, improving both appearance and performance.

6.Fatigue Resistance

Aircraft undergo repeated pressurization cycles and takeoffs/landings. Aluminum alloys are designed to resist microcrack propagation and fatigue failure.

7.Thermal Conductivity and Stability

Aluminum can withstand high temperatures and efficiently dissipate heat, essential in aerospace and electronics applications.

Applications of Aircraft-Grade Aluminum in Aircraft

Aircraft-grade aluminum is a superstar material in aviation. Its unique performance characteristics make it the preferred material for many critical components:

1.Aircraft Wings and Fuselage

Used in main body structures and wings, aluminum's high strength-to-weight ratio allows it to withstand flight stress while keeping the aircraft light, improving fuel efficiency and performance.

2.Aircraft Engines

While engines often involve steel or titanium, aluminum plays a vital role in parts like fan blades and casings, where weight reduction boosts efficiency.

3.Landing Gear

Aluminum sheets are strong and durable enough to handle the stress and impact of landings. Their corrosion resistance ensures long-term reliability, even in harsh environments.

4.Interior Components

Used in seat frames, overhead compartments, and cockpit elements, aluminum reduces total aircraft weight, contributing to better fuel economy while resisting corrosion throughout the aircraft’s lifecycle.

5.Electrical Systems

Thanks to its high conductivity, aircraft-grade aluminum is widely used in wiring and electronic systems, ensuring efficient and reliable power distribution onboard.

Contact Us