5052 aluminum magnesium manganese plate for roof panel

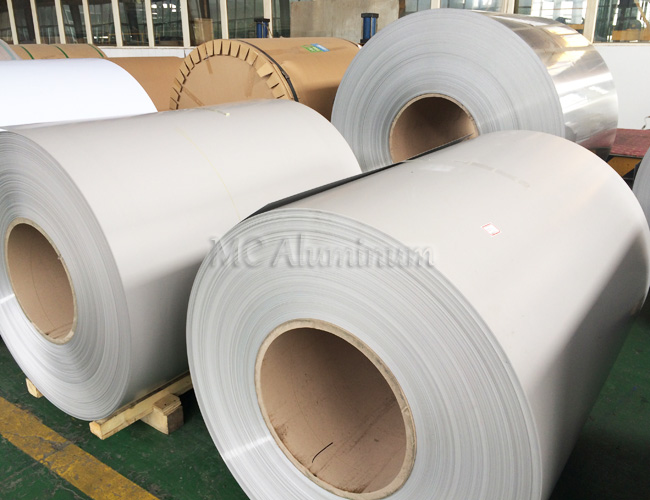

With the development of society, aluminum alloy has received more and more attention as a roofing material. It is widely used in large construction projects such as airports, stations and stadiums. Aluminum-magnesium alloys are light in weight and can be processed in a variety of ways, such as anodizing, electrophoresis, chemical treatment, polishing and painting.

5052 aluminum sheet is an industrial material that is often used in roof panels in architectural design. It is characterized by low density, high tensile strength and high elongation. In addition, 5052 aluminum plate also has moderate structural strength, weather resistance, stain resistance, flexibility and weldability. Therefore, it is generally considered to have a service life of nearly half a century. If you want to deal with building design that is more humid than the conventional climate, you can choose a more corrosion-resistant 5083 aluminum plate for processing.

Advantages of 5052 aluminum-magnesium-manganese panels for roof panels:

1. 5052 aluminum plate achieves higher strength through processing and heat treatment.

2. This aluminum plate has strong corrosion resistance, and there is an aluminum oxide film on the surface, which can prevent metal oxidation and corrosion.

3. The aluminum alloy material can be anodized and colored to make the appearance of the roof panel more diversified.

4. The 5052 aluminum plate can be connected by welding, gluing, etc., so that the processed aluminum-magnesium-manganese roof panel has better heat insulation effect.

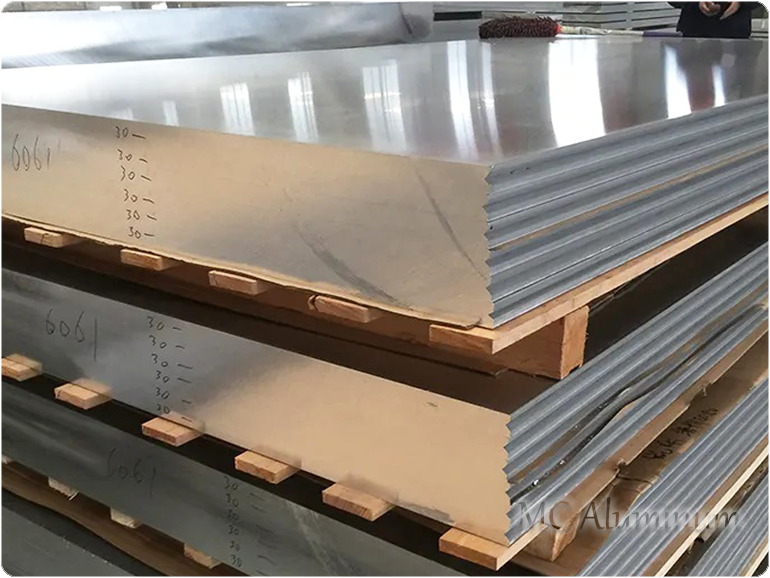

MC Aluminum is a large-scale aluminum sheet manufacturer, specializing in providing roof panels, alumina panels, automotive aluminum panels, curtain walls, etc. The product models are complete, the output is large, and the delivery time is short. It is exported to many overseas countries and regions, and sample mailing services can be provided. , customers can order with confidence.

Contact Us