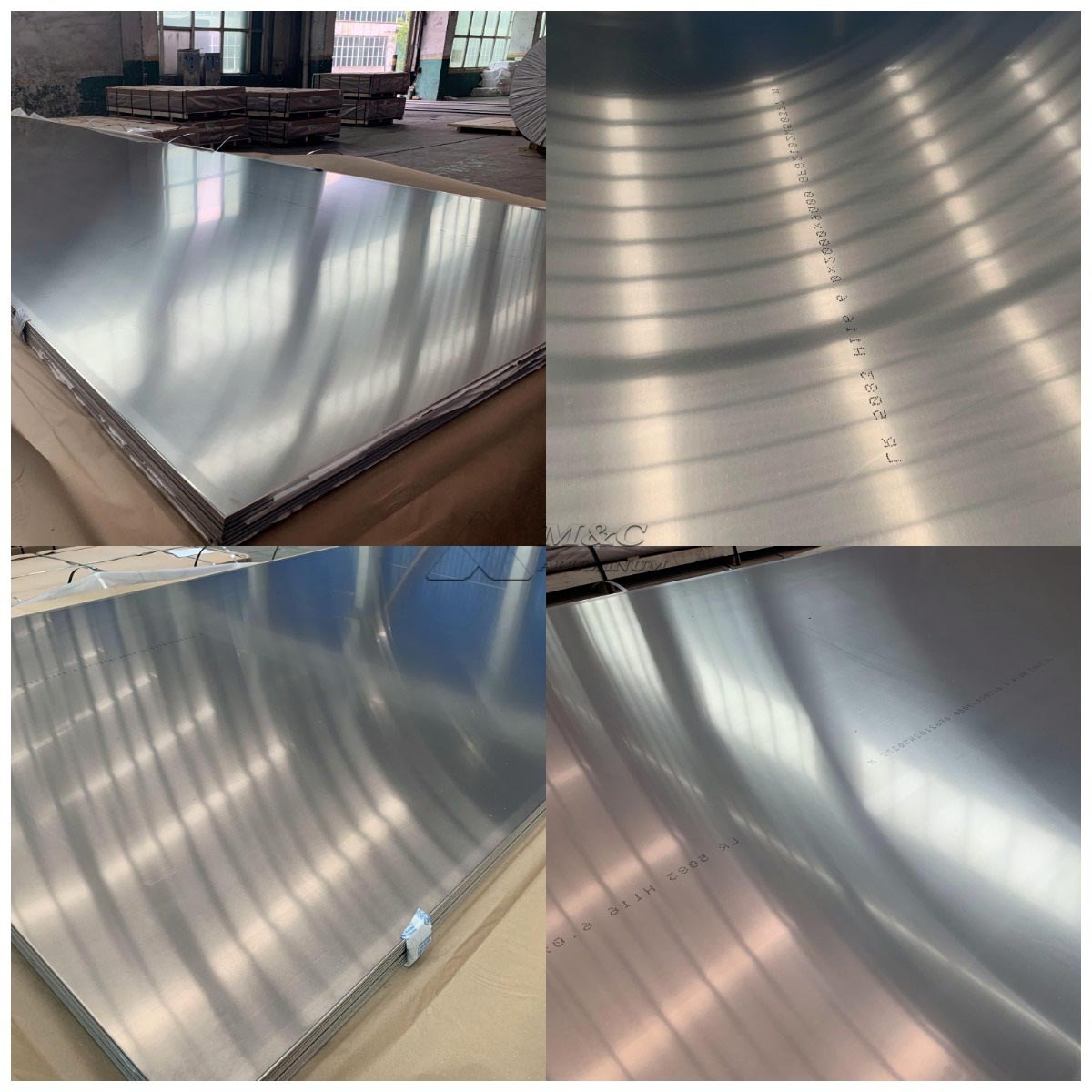

5052 Aluminum Sheet For Small Boat Construction

Small boat builders often face the same practical problems: premature corrosion around weld seams, oil-canning in thin hull plating, distortion after fabrication, and inconsistent forming results when parts move from prototype to repeat production. These issues typically trace back to material selection and temper choice. A sheet that is easy to form may be too soft for dent resistance, while a higher strength option may crack on tight bends or complicate welding. In coastal service, even minor compromises in corrosion resistance can become expensive rework.

5052 aluminum sheet is widely used in small boat construction because it balances corrosion resistance in marine atmospheres, weldability, and reliable forming performance. As a 5xxx series aluminum-magnesium alloy, it is not heat treatable, but it responds well to strain hardening (work hardening) tempers that can be matched to hull, deck, and interior component requirements.

Why 5052 Aluminum Sheet Is Common in Small Boats

For overseas buyers sourcing plate and sheet for skiffs, tenders, pontoons, patrol craft auxiliaries, and workboat subassemblies, 5052 is often selected for three core reasons:

Corrosion resistance in marine exposure: 5052 offers strong resistance to general corrosion in salt-laden air and splash zones. This is particularly valuable for small craft that may be trailered, stored outdoors, or moored with limited coating maintenance.

Excellent fabrication versatility: 5052 is known for good formability and consistent bending behavior in appropriate tempers, helping reduce cracking during press-brake forming, rolling, or flanging.

Weldability suited to production work: 5052 is commonly welded using standard aluminum welding processes, supporting practical assembly of frames, brackets, lockers, and tanks where design allows.

From a procurement perspective, 5052 aluminum sheet also supports stable repeatability across multiple lots, which matters when parts are nested and cut in batches for small boat kits or contract builds.

Material Characteristics of 5052 (5xxx Series Al-Mg)

Corrosion behavior in typical boat environments

In small boat construction, corrosion concerns are not limited to full immersion. Many failures occur in crevices, lap joints, and around fasteners where moisture is trapped. 5052 is valued because it performs well in marine atmospheres and resists the kind of broad surface oxidation that can undermine appearance and lead to pitting under deposits.

Practical considerations still apply: avoid dissimilar-metal contact without isolation, control stagnant water traps, and use suitable fasteners and joint design. Material selection reduces risk, but design and workmanship complete the corrosion strategy.

Strength, stiffness, and dent resistance trade-offs

Small boats often use relatively thin sheet to control weight. Thin plating is more sensitive to local impacts and oil-canning. 5052 in work-hardened tempers (such as H32) offers improved strength over annealed (O) condition while retaining useful forming margins. This makes it a common compromise for hull skins, deck panels, and formed components where moderate strength is needed without sacrificing manufacturability.

Forming performance

5052 is frequently selected when parts require bending, rolling, or drawing, such as:

Gunwale caps and rub-rail backing

Console skins and lockers

Hatches, covers, and formed trays

Brackets with flanges and tight bend radii

Temper choice heavily influences forming reliability, which is why the same alloy may be purchased in different tempers for different parts within the same boat.

Processing Performance: Cutting, Forming, and Welding

Cutting and machining

5052 aluminum sheet can be processed using typical methods used by boat fabricators: shearing, sawing, laser cutting, and waterjet cutting. Buyers should align surface protection requirements (film, paper interleaf) with their cutting method to prevent scratches that later show through coatings or anodized finishes.

Machining is feasible for holes, slots, and edge preparation, though 5xxx series alloys are generally selected more for forming and corrosion performance than for extensive machining.

Bending and rolling

5052 provides stable bending in many applications, but the correct temper is essential. In general terms:

Softer tempers (O) are preferred for tight bends or more complex forming.

Work-hardened tempers (H32/H34) are preferred when formed parts must carry load or resist denting.

For repeat production, it is recommended to qualify bend radii and tooling with the actual temper and thickness, because small changes in temper can materially affect bend outcomes.

Welding behavior

5052 is commonly welded in small craft fabrication for frames, stiffeners, and joined sheet assemblies. Weld design must consider distortion control, heat input, and post-weld finishing. Many build issues attributed to the alloy are actually caused by inadequate fixturing or excessive heat input, especially on thin gauge sheet.

When welding any aluminum, buyers should confirm that the supplied sheet surface condition is suitable for their process (clean, consistent, and free from residues that could affect weld quality).

Common Tempers of 5052 and Where They Fit

Temper selection should be driven by forming severity, load requirements, and cosmetic expectations. Below are common scenarios for 5052 sheet in small boats.

5052-O (annealed)

Best for: maximum formability.

Typical small-boat uses include deep bends, tight radius flanges, and formed components where cracking risk must be minimized. It is also useful for prototypes where geometry may change and parts may be reworked.

5052-H32

Best for: balanced formability and higher strength.

5052 H32 is widely used for boat skins, decks, and general fabricated parts where improved dent resistance and stiffness are desired without sacrificing reasonable bendability. Many overseas buyers specify this temper as a general-purpose option for marine grade aluminum sheet requirements.

5052-H34

Best for: higher strength with reduced forming margin.

H34 may be selected for flatter panels, stiffener webs, or parts where the design does not require tight bends. If the build involves aggressive forming, H34 can increase cracking risk compared with H32.

5052-H36 (less common in small craft forming)

Best for: higher strength where minimal forming is required.

H36 is typically chosen only when the part geometry is simple and strength is prioritized. For small boats with many formed brackets and edges, it is less frequently used than H32.

Typical Uses of 5052 Aluminum Sheet in Small Boat Construction

5052 aluminum sheet supports a wide range of boat components, especially where corrosion resistance and fabrication flexibility are both required.

Hull and deck related parts

While some builders prefer other 5xxx alloys for specific hull plating strategies, 5052 is commonly used for:

Deck plates and walking surfaces (with suitable finish or tread pattern)

Interior hull liners and protective panels

Access covers and hatch lids

Transom and console skins (as part of assemblies)

Tanks and enclosures

5052 is often used for:

Fuel and water tank skins (where allowed by the design and fabrication practice)

Battery boxes and electrical enclosures

Storage lockers and seating bases

Brackets, rails, and formed accessories

Because it is workable and corrosion resistant, 5052 is frequently selected for:

Mounting brackets and reinforcing plates

Rail bases, steps, and platforms

Equipment guards and splash shields

5052 Aluminum Plate Technical Parameters

| Alloy | 5052 |

| Temper | O,H32,H34,H36 |

| Thickness | 3-50mm |

| Width | 1000-2650mm |

| Length | 1000-16000 |

| Density | 2.68 g/cm³ |

| Elastic modulus | 70 GPa |

| Coefficient of thermal expansion | 23.8 × 10⁻⁶ /K |

| Thermal conductivity | ≈138 W/m·K |

| Electrical conductivity | ≈35 %IACS |

| MOQ | 1-3 tons |

Mechanical properties

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5052-O | ≥170 | ≥65 | ≥25 |

| 5052-H32 | ≥215 | ≥160 | ≥12 |

| 5052-H34 | ≥235 | ≥180 | ≥10 |

| 5052-H36 | ≥260 | ≥200 | ≥8 |

Selection Considerations for Overseas Procurement

Thickness, flatness, and surface expectations

Small boat parts often demand good flatness for panel fit-up and reduced rework. Surface requirements differ by application:

Structural hidden parts prioritize thickness tolerance and consistency.

Visible parts may prioritize surface finish, freedom from roll marks, and protective packaging.

When ordering, specify whether the sheet will be left mill finish, painted, or coated, and whether a protective film is required.

Matching alloy and temper to fabrication steps

A practical approach for mixed boat builds is to separate material by function:

Use 5052-O for tight-formed parts (complex bends, rolled corners).

Use 5052-H32 for general panels needing better stiffness and dent resistance.

Use 5052-H34 where strength is valued and forming is limited.

This reduces scrap rates, improves dimensional repeatability, and minimizes distortion problems that show up late in assembly.

Positioning among other marine aluminum options

In global sourcing, 5052 often sits between more formable general-purpose alloys and higher-strength marine-focused 5xxx alloys. If a build requires higher strength or specific hull plating practices, buyers may compare 5052 with alternatives such as 5083 or 5086, but for many small boat components, 5052 remains a practical baseline due to its fabrication balance.

For buyers standardizing their supply chain, maintaining a consistent specification for 5052 Aluminum Sheet can simplify qualification across multiple subcontractors. When broader sourcing is needed across alloys and tempers, a consolidated category approach for Aluminum Sheets helps align packaging, tolerances, and documentation expectations.

Contact Us