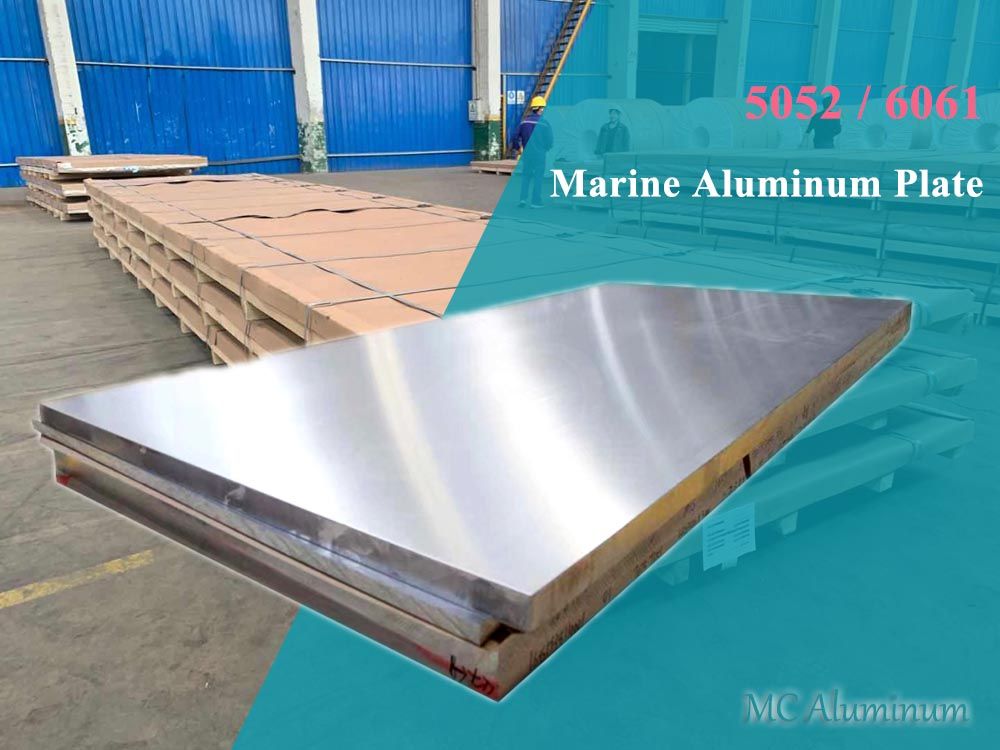

5052 vs. 6061 Aluminum Alloy: Which Alloy Is More Suitable for Marine Applications?

In the fields of shipbuilding and marine engineering, material selection directly affects structural safety, service life, and total life-cycle cost. Thanks to their lightweight characteristics, corrosion resistance, and good processability, aluminum alloys are widely used in hull structures, decks, cabins, and various marine components. Among them, 5052 aluminum alloy and 6061 aluminum alloy are the two most frequently compared materials. So which alloy should users choose when making a purchase? The following provides a detailed explanation.

Product Introduction

5052 Marine Aluminum Alloy

5052 aluminum alloy is a typical Al-Mg (aluminum–magnesium) corrosion-resistant alloy and one of the most widely used marine aluminum materials. With a magnesium content of approximately 2.2%-2.8%, it maintains lightweight characteristics while offering excellent resistance to seawater corrosion. It is widely used in hull plating, decks, fuel tanks, and similar applications.

Material Features

1.Excellent resistance to seawater corrosion, with high stability in salt spray and humid environments

2.Good formability, suitable for cold bending and roll forming

3.Stable weldability with minimal post-weld property degradation

4.Moderate strength, suitable for non-load-bearing or secondary load-bearing structures

Common Tempers

O temper (annealed): suitable for deep drawing and complex forming

H32 / H34: standard marine tempers balancing strength and formability

6061 Marine Aluminum Alloy

6061 aluminum alloy is a heat-treatable, medium-to-high strength corrosion-resistant alloy. In marine applications, it is typically used for components requiring higher strength, such as masts, gangways, decks, hull frames, and marine machinery parts.

Product Features

1.High strength and rigidity, suitable for load-bearing and support structures

2.Excellent machinability, ideal for CNC machining

3.Stable mechanical properties achieved through heat treatment (T6)

Common Tempers

T6: preferred for high-strength structural components

T651: suitable for parts requiring better flatness and machining stability

Marine Aluminum Alloys: 5052 vs. 6061

1. Chemical Composition

5052 Aluminum Alloy: primarily composed of aluminum (Al), magnesium (Mg), and manganese (Mn), offering excellent corrosion resistance and ductility.

6061 Aluminum Alloy: primarily composed of aluminum (Al), silicon (Si), zinc (Zn), and magnesium (Mg). It provides higher strength, though with slightly reduced weldability.

2. Corrosion Resistance

5052 Aluminum Alloy: Rich in magnesium, 5052 naturally forms a dense protective oxide layer. Even if the surface is scratched, the metal can self-repair, making it ideal for hulls continuously exposed to saltwater.

6061 Aluminum Alloy: Offers good corrosion resistance, but is more prone to pitting corrosion during long-term saltwater immersion. While it performs well in freshwater environments, marine applications typically require high-quality marine-grade coatings or paints.

3. Processing Performance

(1) Weldability

5052 Aluminum Alloy: Excellent weldability with low thermal stress, suitable for complex curved structures.

6061 Aluminum Alloy: Experiences significant strength reduction after welding and usually requires post-weld heat treatment to restore properties.

(2) Cutting and Stamping

5052 Aluminum Alloy: Lower cutting and stamping costs; smooth surface suitable for coating or decorative finishing.

6061 Aluminum Alloy: Generates more heat during cutting and requires more specialized equipment.

4. Mechanical Properties

5052 Aluminum Alloy: Yield strength ≈ 190 MPa; moderate strength and easy forming through cold working.

6061 Aluminum Alloy: Yield strength ≈ 270 MPa, approximately 40% higher than 5052, making it suitable for load-bearing structures.

5. Weight and Cost

5052 Aluminum Alloy: Density ≈ 2.68 g/cm³, about 3% lighter than 6061, resulting in lower transportation and fuel consumption.

6061 Aluminum Alloy: Density ≈ 2.70 g/cm³; approximately 10-15% higher in cost, but offers higher strength per component.

6. Application Areas

5052 Aluminum Alloy: Widely used for hull plating, hatch covers, decks, and other corrosion-resistant components.

6061 Aluminum Alloy: Commonly used for hull frames, support beams, and internal structures requiring higher strength.

Conclusion

In practical applications, many shipbuilders combine the advantages of both alloys: using 5052 aluminum alloy for the hull exterior to ensure corrosion resistance, and 6061 aluminum alloy for internal frames to enhance overall strength. This "hybrid" approach achieves an optimal balance of lightweight design, cost efficiency, and high reliability.

Why Choose Us?

1.Strict chemical composition control to ensure consistent performance across batches

2.Ability to supply plates compliant with classification society certifications (such as CCS, ABS, DNV, etc.)

3.Wide range of sizes and thicknesses, with custom cutting to reduce material waste

4.Optional pre-polishing, passivation, or coating services to reduce downstream processing for shipyards

Contact Us