Flexible Aluminum Foil Packaging for Dairy Products

Thanks to its lightweight structure, high strength, and excellent barrier performance, flexible aluminum foil packaging has become an ideal solution for dairy products such as milk, yogurt, butter, and cheese, and is now commonly seen on supermarket shelves.

Flexible aluminum foil packaging typically uses aluminum foil as the core barrier layer, which is laminated with plastic films, paper, or other materials to form a multilayer composite structure. Combining flexibility, heat-sealability, and high barrier properties, it is widely used for dairy product sealing, pouches, lids, roll stock, and laminated packaging.

Multilayer Composite Structures

Pure aluminum foil is relatively brittle and has limited heat-sealing capability. Therefore, in practical applications it is usually laminated with other materials to create multilayer structures. Common constructions include:

PET / Aluminum Foil / CPP

The outer PET layer provides rigidity and excellent printability, the middle aluminum foil acts as the primary barrier, and the inner CPP layer enables reliable heat sealing. This structure is suitable for snacks and dry food packaging.

BOPP / Aluminum Foil / PE

BOPP improves stiffness and appearance, while the PE inner layer offers strong heat-sealing performance. Commonly used for daily consumer goods and food seasoning packaging.

Nylon / Aluminum Foil / PE

The nylon layer enhances puncture resistance, making it suitable for products containing oils, fats, or sharp particles.

PVDC / Aluminum Foil / PE

The addition of a PVDC coating further improves oxygen and moisture barrier properties, ideal for high-moisture and easily oxidized foods.

Core Advantages of Flexible Packaging Foil

1.Outstanding Barrier Properties

Aluminum foil can almost completely block oxygen, water vapor, light, and odors, effectively extending product shelf life.

2.High Safety Level

Flexible aluminum foil used for dairy products typically adopts food-grade aluminum foil (such as 8011, 8079, and 1235 alloys) and complies with FDA, EU, and GB food-contact standards. It is non-toxic, odorless, and does not migrate harmful substances.

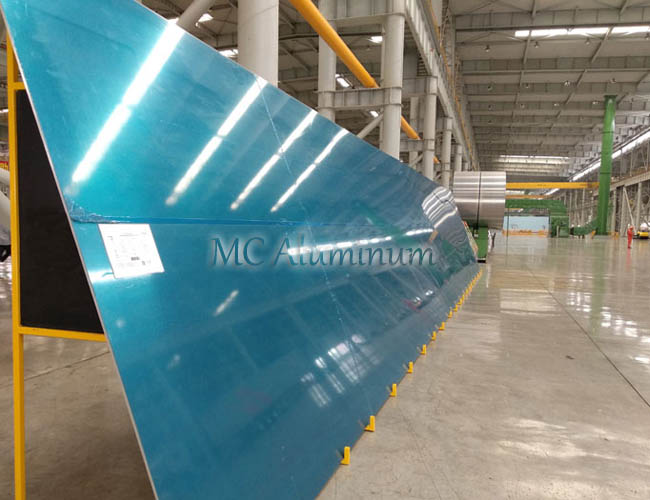

3.Excellent Processability

Aluminum foil offers good formability and can be processed through die-cutting, embossing, laminating, and printing.

4.Lightweight Efficiency

Ultra-thin aluminum foil delivers exceptionally high performance while significantly reducing overall packaging material usage.

5.Aesthetic Appeal

Advanced printing technologies allow vibrant graphics, brand logos, and nutritional information to be printed on the foil, meeting diverse market demands.

6.High-Temperature Resistance

Aluminum foil laminated films can withstand high-temperature sterilization processes, meeting the strict requirements of aseptic filling.

Technical Specifications

| Alloy & Temper | 8011-O / 8079-O / 1235-O |

| Aluminum Foil Thickness | 6-12 μm |

| Total Laminate Thickness | 40-120 μm |

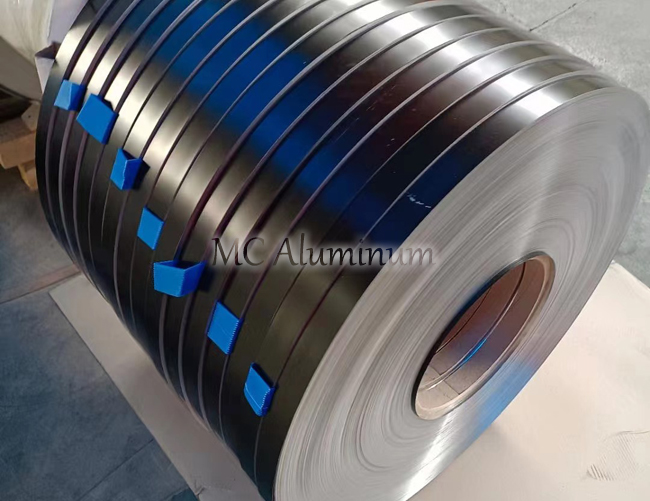

| Width | 10-1600 mm |

| Length | Customizable |

| Surface Treatment | Single-sided or double-sided coating, printing |

| Heat-Sealing Temperature | 130-200°C (depending on structure) |

| Applicable Processes | Laminating, printing, die-cutting, heat sealing |

| Applications | Yogurt, cheese, and other dairy packaging |

| MOQ | 1-3 tons |

Typical Applications of Flexible Aluminum Foil in Dairy Products

1. Yogurt Lids

One of the most common applications, used for yogurt cups and cheese containers. Aluminum foil provides excellent sealing performance to prevent leakage while offering good peelability, enhancing consumer convenience and user experience.

2. Butter and Cheese Wrapping Foil

Aluminum foil features excellent dead-fold properties, meaning it stays in place after folding without springing back. This allows it to closely wrap the product, minimize internal air, and prevent fat oxidation.

3. Laminated Layer in Tetra Pak and Tetra Fino Packages

In shelf-stable liquid milk packaging, the extremely thin aluminum foil layer (typically only 6-7 microns) is the key element that enables long-term preservation at ambient temperature.

Contact Us