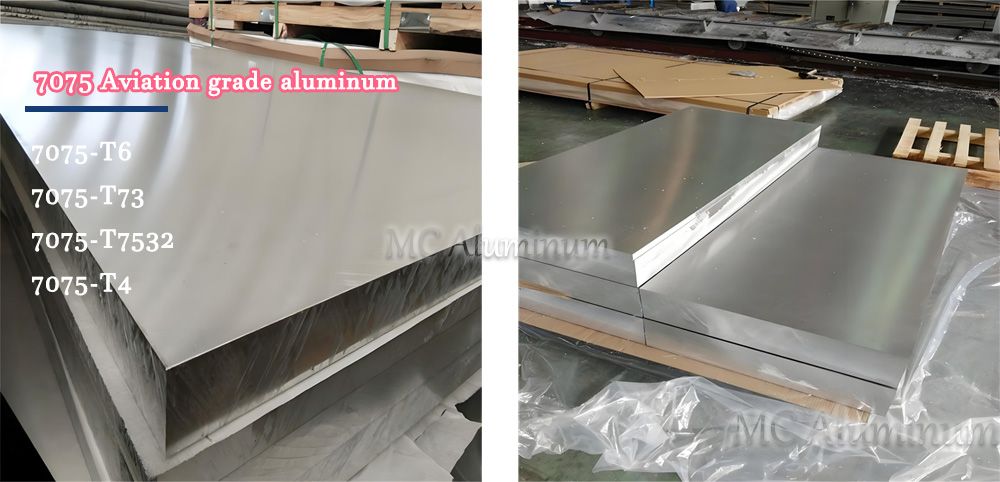

Forged 7075-T6 Aerospace-Grade Aluminum

Historical Background

The development of 7075 aluminum alloy can be traced back to World War II, when it was specially designed for aircraft manufacturing to meet the demanding requirements of strength and weight reduction. Its historical significance highlights its foundational role in the evolution of aircraft design—advancing speed, range, and payload capacity.

What Is 7075-T6 Aluminum?

7075 belongs to the Al-Zn-Mg-Cu family (aluminum-zinc-magnesium-copper), a heat-treatable high-strength aluminum alloy. Its main alloying element is zinc, supplemented by magnesium, copper, and trace amounts of titanium, forming a unique metal matrix that gives the alloy exceptional mechanical performance.

The "T6" designation refers to its heat treatment process: solution heat treatment + artificial aging. This process promotes the formation of the η (MgZn₂) precipitate phase, which significantly enhances the alloy’s tensile and yield strength.

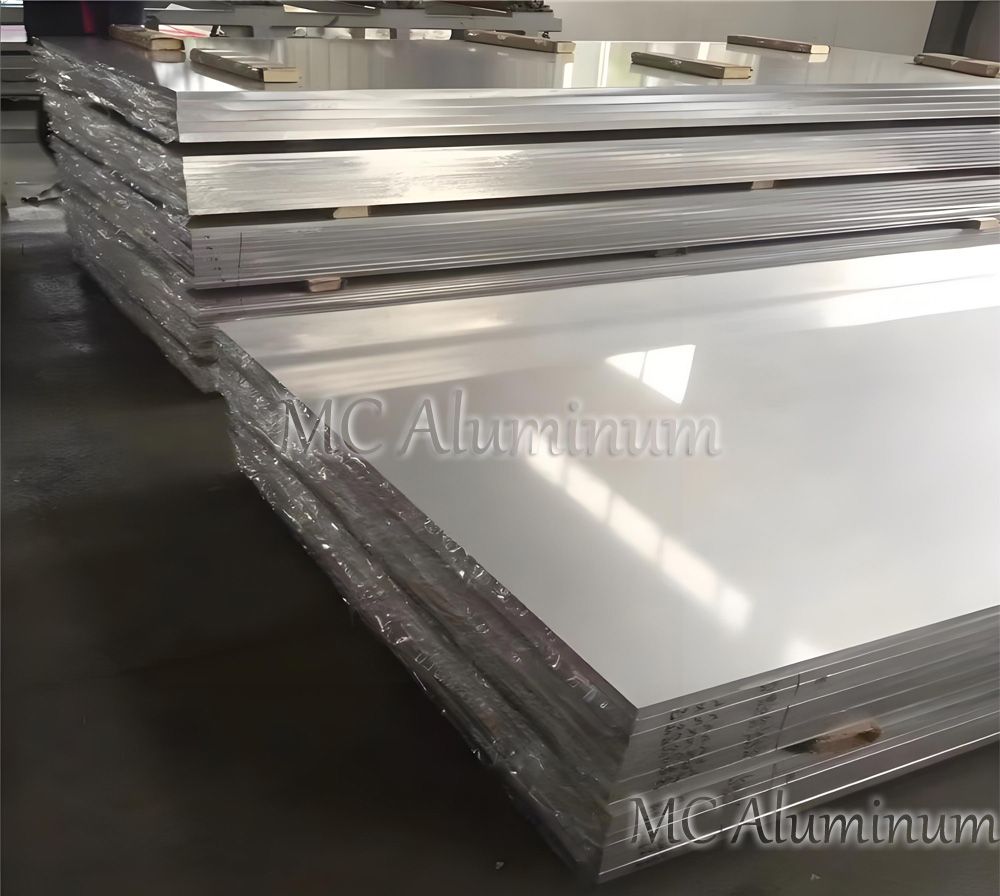

7075-T6 aluminum alloy is renowned for its high strength, low weight, and excellent structural stability, making it ideal for aerospace, motorsports, and precision mold manufacturing—any application requiring high performance under stress. It maintains its shape and strength even in high-stress environments, earning its place as a quintessential "structural aluminum."

Features of Forged 7075-T6 Aerospace-Grade Aluminum

“Forged” 7075-T6 aluminum refers to aluminum processed through forging—a technique that applies heat and pressure to significantly increase the metal's strength and density compared to casting.

Closed-die forging improves grain flow alignment, boosting fatigue resistance by over 30% compared to cast parts. This results in stronger, more durable components with a longer service life and higher quality.

Surface Treatments

Anodizing: A common surface treatment for 7075-T6, enhancing corrosion and wear resistance. However, certain tempers like 7075-T651 may require special process control to ensure uniform results without compromising material integrity.

Coating & Painting: Used for additional protection and aesthetics. To avoid surface issues from machining (e.g., coolant stains), it is recommended to apply surface treatments immediately after machining for consistent quality and efficiency.

Chemical Composition of 7075 Aluminum Alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | remainder |

Mechanical Properties of 7075-T6 Aluminum

| Property | Metric | Imperial |

| Ultimate Tensile Strength | 572 MPa | 83,000 psi |

| Yield Strength | 503 MPa | 73,000 psi |

| Brinell Hardness | 150 | 150 |

| Rockwell A Hardness | 53.5 | 53.5 |

| Rockwell B Hardness | 87 | 87 |

| Vickers Hardness | 175 | 175 |

| Elongation at Break | 11% | 11% |

| Fatigue Strength | 159 MPa | 23,000 psi |

| Shear Strength | 331 MPa | 48,000 psi |

| Modulus of Elasticity | 71.7 GPa | 10,400 ksi |

Aerospace Advantages of 7075-T6 Aluminum Alloy

1. Exceptional Strength-to-Weight Ratio

7075-T6's strength is comparable to some steels but with significantly lower weight. This is crucial in aerospace, where weight reduction directly improves fuel efficiency, payload capacity, and aircraft performance. It allows engineers to design smaller, lighter components without sacrificing durability.

2. Outstanding Fatigue Resistance

Aircraft components undergo countless load/unload cycles during operation. Fatigue resistance is critical for longevity and safety.

7075-T6 offers excellent fatigue performance with a fatigue strength of 159 MPa—superior to 2024 (138 MPa) and 6061 (96.5 MPa). This ensures longer service life under cyclic stress.

3. High Toughness

7075 aerospace aluminum maintains high toughness, making it durable under high-stress applications and resistant to crack propagation.

4. Thermal Management

With high thermal conductivity, 7075-T6 facilitates fast heat dissipation, which is essential in preventing overheating of engine components and other sensitive aircraft parts.

5. Formability and Surface Finishing

Though it has some limitations in formability, 7075-T6 is still viable for certain forming applications. It also readily accepts coatings and finishes, satisfying both protective and aesthetic requirements.

6. Corrosion Resistance and Durability

7075-T6 exhibits good resistance to atmospheric corrosion and humid environments, maintaining strength over time. It also has excellent resistance to stress corrosion cracking, making it reliable in high-load and corrosive conditions, minimizing structural fatigue failure risks.

Applications

7075 aerospace aluminum is extensively used in the aerospace industry for:

Aircraft structural components: upper/lower wing skins, ribs, spars

Missile parts

Landing gear components

Fuselage frames

Other high-strength critical aircraft components

Comparison with Other Aerospace Aluminum Alloys

| Alloy | Strength | Weldability | Corrosion Resistance | Machinability | Typical Uses |

| 6061-T6 | Medium | Excellent | Excellent | Excellent | General structural applications |

| 2024-T3 | High | Moderate | Moderate | Moderate | Aircraft skin, structures |

| 7075-T6 | Very High | Poor | Moderate | Excellent | Aerospace, defense, motorsports |

Summary: 7075-T6 surpasses both 6061 and 2024 in strength but has lower weldability and moderate corrosion resistance. This requires consideration during design—favoring mechanical fastening over welding and applying post-treatment as needed.

Contact Us