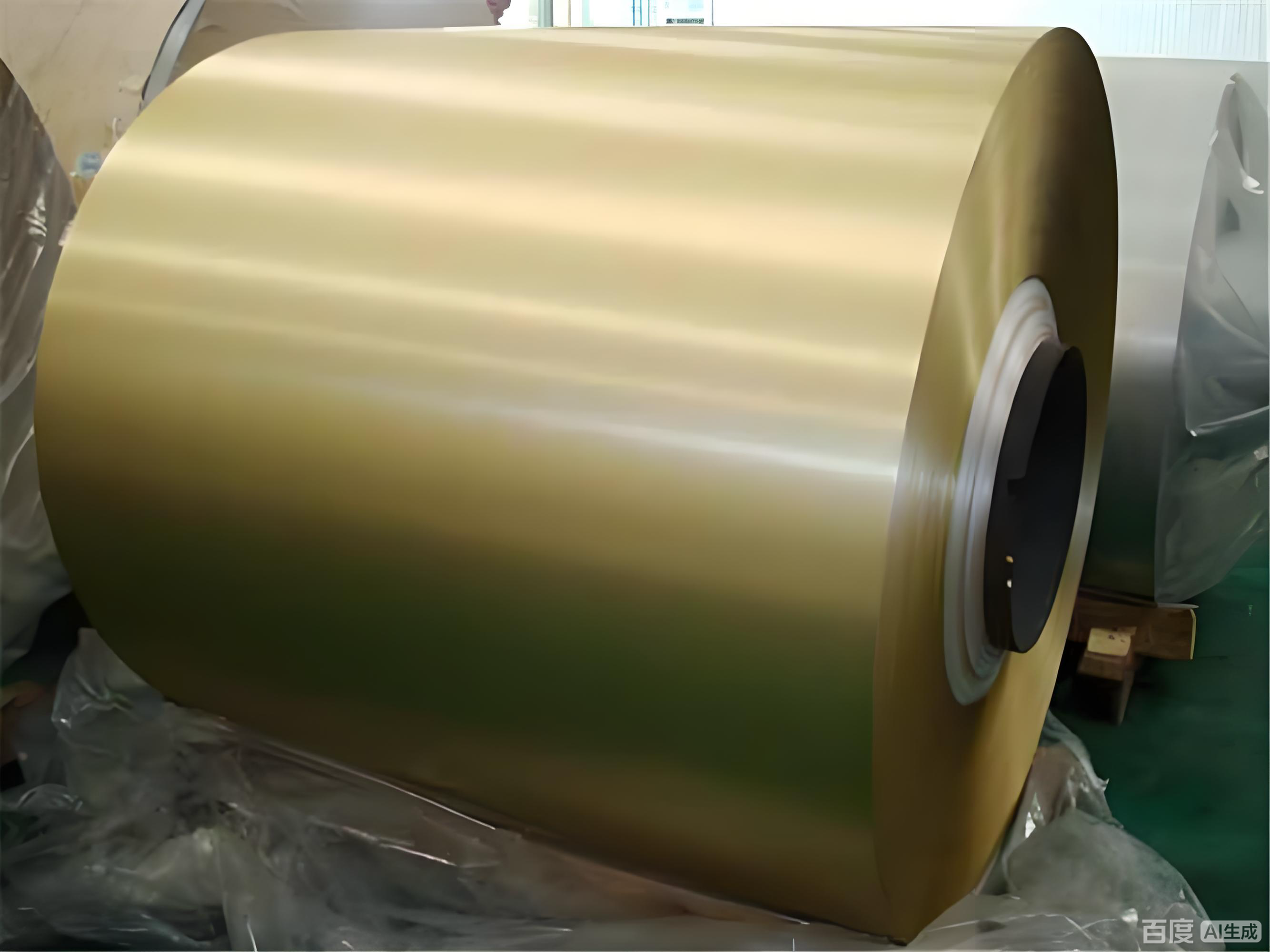

Gold Epoxy Resin Coated Aluminum Foil

Gold epoxy resin coated aluminum foil is made from high-purity aluminum foil that is coated with an epoxy resin layer and cured through a controlled baking process. The surface presents a glossy or matte gold appearance and offers excellent corrosion resistance, heat resistance, moisture protection, and mechanical strength. These properties make it widely used in packaging, industrial applications, decorative materials, and electronics.

Epoxy coated foil is commonly produced using 1235 or 8011 aluminum foil, with a typical thickness range of 0.006-0.03 mm and widths from 100-1600 mm, suitable for downstream slitting and conversion.

Gold epoxy coated foil is mainly categorized into hydrophilic and hydrophobic types:

| Property Dimension | Gold Epoxy Hydrophilic Foi | Gold Epoxy Hydrophobic Foil |

| Surface Behavior | Stable hydrophilicity allows water to spread evenly. | Stable hydrophobicity enables water droplets to roll off quickly. |

| Working Environment | Suitable for systems operating under acidic conditions. | Designed for harsh environments with high humidity or condensation. |

| Protection Focus | Prevents corrosion and optimizes water film distribution during heat exchange. | Excellent moisture resistance and anti-condensation performance, preventing corrosion caused by long-term water retention. |

Technical Specifications of Epoxy Coated Aluminum Foil

| Alloy | 8011 H18 / 1235 H19 |

| Thickness | 0.006 - 0.03 mm |

| Width | 20 - 1600 mm |

| Length | 1000 - 16000mm |

| Coating Type | Epoxy resin coating |

| Coating Thickness | 2 - 10 μm |

| Surface Colors | Gloss gold, matte gold, brushed gold |

| Temperature Resistance | -40°C to 150°C |

| Core ID | 405 mm / 505 mm |

| Protective Film | Single-side or double-side optional |

| Applications | Air conditioners, packaging, electronic components, etc. |

| MOQ | 1-3 tons |

Advantages of Gold Epoxy Coated Aluminum Foil

1. Outstanding Corrosion Resistance

The epoxy layer forms a dense protective barrier that effectively blocks acids, alkalis, and salts. This makes it highly suitable for environments with corrosive media or high humidity.

2. Excellent Adhesion

Epoxy resin bonds strongly with the aluminum surface, ensuring the coating does not peel or flake during forming, bending, slitting, or further processing.

3. Electrical Insulation

Epoxy coatings provide superior electrical insulation, making the material an ideal choice for electronic parts and capacitor packaging.

4. High Temperature Resistance

With heat resistance up to 150°C, the foil withstands thermal sealing, laminating, and hot stamping processes without cracking or discoloration.

5. Superior Processability

The excellent ductility of aluminum allows the foil to be easily bent, embossed, slit, or laminated to meet the requirements of packaging, electronics, decorative products, and industrial parts.

6. Weather Resistance

The coating has moderate UV resistance, ensuring stable color and minimal fading during long-term use.

7. Premium Metallic Appearance

The rich gold color and stable gloss level make it suitable for high-end packaging, cigarette inner liners, and decorative applications, adding a luxurious visual effect.

Applications of Gold Epoxy Resin Coated Aluminum Foil

1. Heat Exchange Industry

Used in fin stock for air conditioners and corrosion-resistant heat exchangers operating in acidic or harsh environments.

2. Premium Packaging

Ideal for high-grade cigarette packaging, alcoholic beverages, cosmetics, and luxury gift boxes, offering a brighter and more premium finish compared to plain aluminum foil.

3. Industrial Anti-Corrosion

Applied in insulated building panels, HVAC air duct lining, and other applications requiring insulation and corrosion protection.

4. Pharmaceutical Industry

Used for PTP blister foil, medical dressings, and sterile inner liners where high sealing performance is required.

Contact Us