Processing Technology of Marine Grade 5083 Aluminum Alloy Thick Plate

The marine-grade 5083 aluminum alloy thick plate is a core lightweight material in the marine engineering field. With its unique overall performance, it has become an indispensable metal base material in modern shipbuilding. This alloy, based on aluminum-magnesium composition, offers excellent seawater corrosion resistance, medium strength, and good cold working and welding properties. It significantly reduces ship weight and improves fuel efficiency, aligning with the global goals of "carbon peak" and "carbon neutrality" for green development.

In shipbuilding applications, 5083 medium-thick aluminum plates are not only used for the main structural components such as the hull and deck but also exhibit outstanding performance in critical applications like liquefied natural gas (LNG) storage tanks and high-pressure vessels. Its resistance to low-temperature brittleness, non-magnetic properties, and recyclability further expand its application scope in high-end equipment manufacturing. The marine aluminum plates produced by MC Aluminum Industry have been certified by classification societies such as BV, LR, ABS, and CCS, ensuring the material meets marine engineering standards. The 5083 aluminum alloy thick plate is driving the shipbuilding industry toward lightweight, high-reliability, and long-service-life advancements.

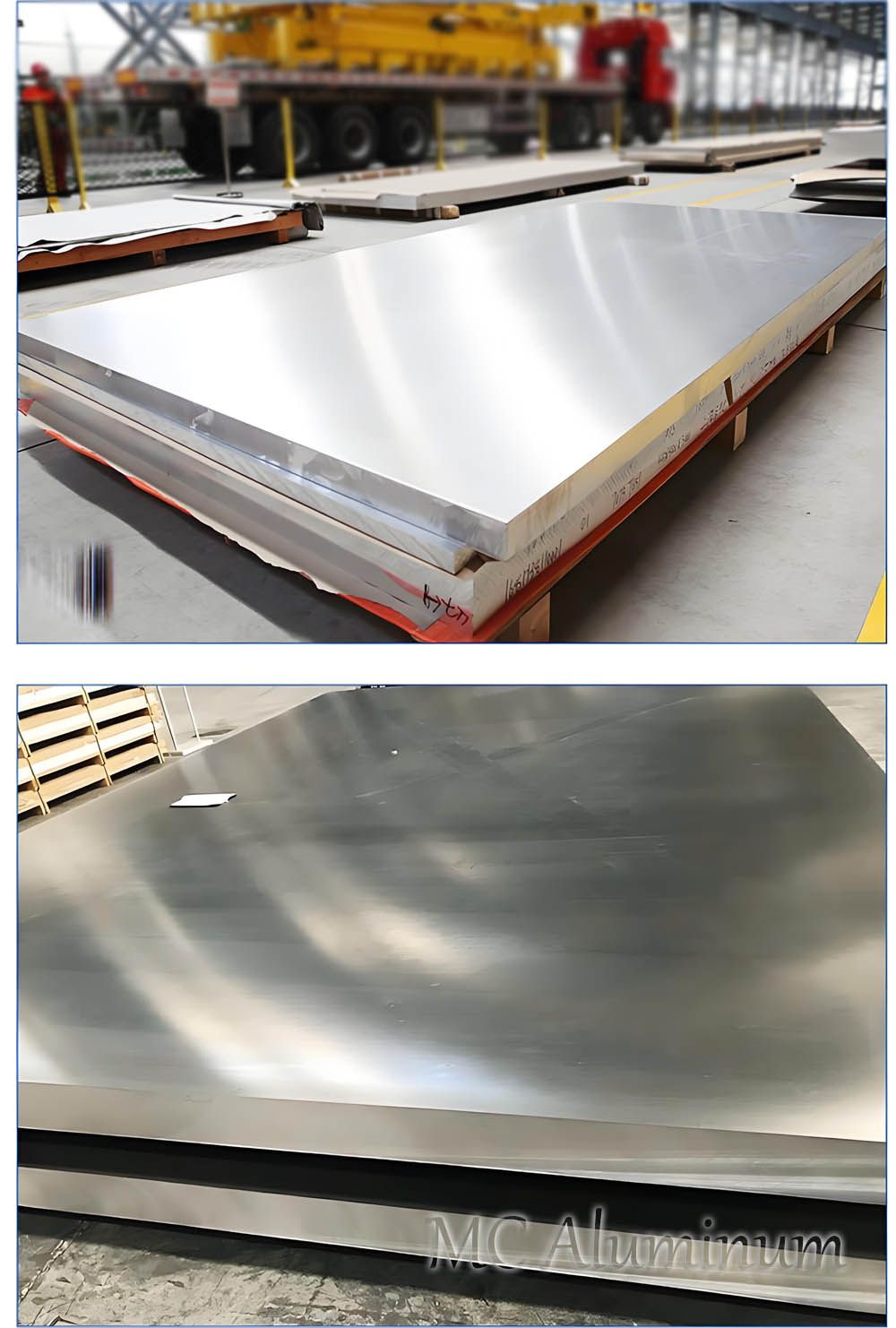

Thickness Specifications of 5083 Medium and Thick Aluminum Plates:

Medium Plate Definition: 6.0-25mm (medium plate), 25-200mm (thick plate), ultra-thick plates can reach up to 600mm.

Common Marine Grade Thickness: 1.5-30mm, width 1000-3100mm, length customizable up to 13000mm.

Processing Technology of 5083 Marine Aluminum Plate:

The 5083 aluminum alloy ingot undergoes a series of processes including milling, heating, hot rough rolling, shearing, stretching and straightening, and sawing to the required length, resulting in marine-grade 5083 aluminum alloy thick plates.

Core Characteristics of 5083 Marine-Grade Aluminum Plate:

1. Excellent Corrosion Resistance: Performs exceptionally well in seawater, salt mist, and humid environments, making it ideal for ships and offshore platforms.

2. Good Weldability: Can be reliably welded using conventional welding processes (TIG, MIG), with welding strength and corrosion resistance comparable to the base material.

3. High Strength and Fatigue Resistance: Ensures excellent tensile strength while maintaining lightweight properties, capable of withstanding various mechanical loads in marine environments.

4. Lightweight Design: Lighter than steel, reducing ship weight, enhancing payload capacity, speed, and fuel efficiency.

5. Excellent Machinability: Best formability in the annealed (O-temper) state, followed by H32/H34 temper, supporting deep drawing, stamping, and other processes.

6. High-Temperature Performance: Maintains good strength and plasticity at higher temperatures, suitable for high-temperature environments.

Applications of Marine Grade Aluminum Plate:

Ship Structures: Widely used for hulls, decks, bulkheads, engine rooms, etc. Its corrosion resistance extends service life, making it ideal for high-speed vessels, passenger ships, and cargo ships.

Offshore Platforms: Used in marine engineering applications such as offshore wind platforms and offshore drilling rigs, offering seawater corrosion resistance and impact resistance against waves, making it suitable for structural components and ship hulls.

Naval Ships and Vessels: Important in the construction of naval ships and vessels, providing lightweight, corrosion resistance, and fatigue resistance, offering high strength and anti-corrosion properties.

Lifeboats and Watercraft: Used in lifeboats, speedboats, and other watercraft to ensure safety and reliability in complex water environments.

Contact Us