PVDF / PE Color Coated Aluminum Coil for Roller Shutters

Roller shutters are widely used in commercial storefronts, industrial plants, warehouse logistics, and residential garages. Traditionally, roller shutters were made from galvanized steel sheets or ordinary coated panels. However, these materials often fall short in terms of weather resistance, corrosion resistance, and aesthetic appeal. In recent years, color coated aluminum coils have become the mainstream material for roller shutter manufacturing, thanks to their superior overall performance.

What is color-coated aluminum coil?

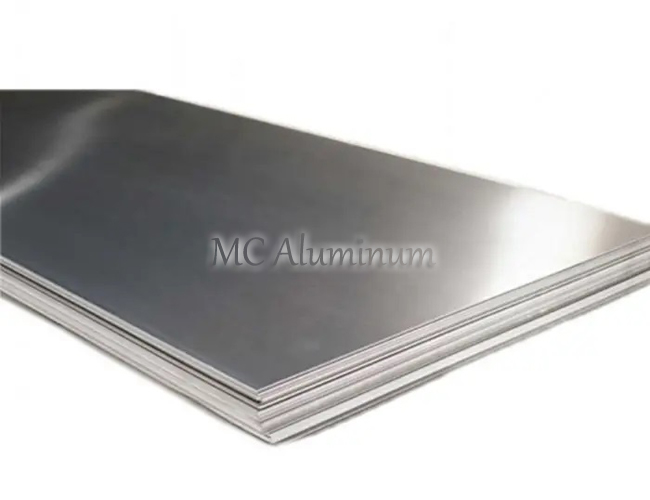

Color-coated aluminum coil is a functional sheet material made from high-quality aluminum alloy strip, processed through a series of processes including surface pretreatment, roller coating, and high-temperature curing. Based on the type of coating, it can be divided into two main categories: **PVDF (fluorocarbon coating) and color-coated PE (polyester coating).** Both types of color-coated aluminum coil are lightweight, aesthetically pleasing, corrosion-resistant, and easy to form, making them ideal for rolling shutter door manufacturing.

PVDF Coated Aluminum Coil uses polyvinylidene fluoride resin as the main film-forming substance. It offers excellent weather resistance, a service life of 20-30 years, and outstanding UV and chemical resistance.

PE Coated Aluminum Coil uses polyester resin as the primary film-forming material. It features vibrant surface colors, excellent processing performance, and a lower cost, making it suitable for medium-weather-resistance applications.

Color-Coated Aluminum Coil Alloys

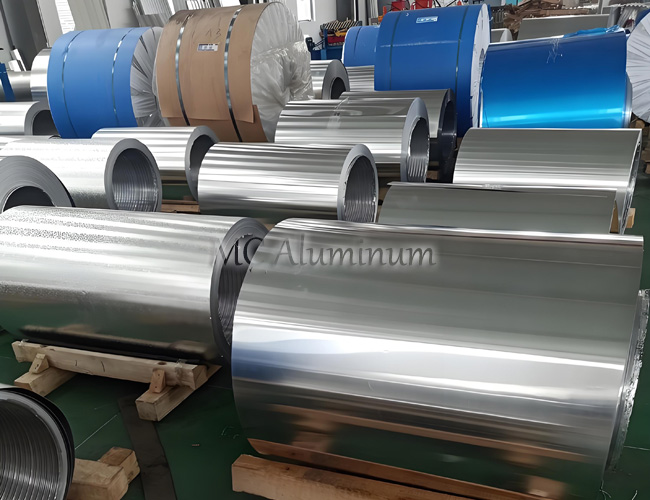

Common alloys for color-coated aluminum coil include 1060, 1100, 3003, 3004, 3105, and 5052. Thicknesses typically range from 0.2mm to 1.2mm, and widths can be slit to meet customer needs.

Why Choose Color Coated Aluminum Coil for Roller Shutters?

1. Lightweight with High Strength

Although aluminum is lightweight, alloying and processing give it the required strength. This reduces the overall weight of the shutter door, lowering the load on the motor and track system.

2. Excellent Weather Resistance

PVDF coatings in particular provide outstanding UV resistance and corrosion protection, ensuring long-term performance against rain, sunlight, and salt spray in coastal environments. The material maintains stable color and structural integrity over time.

3. Rich Colors & Decorative Appeal

Available in a wide range of colors (anti-scratch white, black, beige, reddish brown, silver gray, champagne silver, etc.), as well as wood-grain and stone-grain finishes, enabling diverse architectural design options.

4. Superior Processability

Aluminum is easy to shape and form, ideal for roll forming into shutter slats, which enhances production efficiency.

5. Long Service Life

High-quality PVDF coated aluminum coils can last more than 20 years.

6. Low Maintenance Costs

The smooth surface resists dirt, is easy to clean, and will not rust. No special maintenance is required.

Available Sizes and Specifications

Thickness: 0.02mm - 3.00mm (based on application needs)

Width: up to 1,500mm; customized sizes available

Coil Length & Weight: custom lengths available; industrial-grade coils can weigh up to 5 tons

Colors & Finishes: solid colors, metallic tones, matte, gloss, or textured surfaces; custom RAL color matching available for precise branding and design needs

Why Choose Us?

1. High-Quality Base Material: We use premium 3000- and 5000-series aluminum alloys, with degreasing and chemical pretreatment for enhanced coating adhesion.

2. Advanced Coating Process: International continuous roller coating lines ensure uniform coating thickness and stability.

3. High-Temperature Curing: Baked at around 200°C, forming a dense bonding layer between coating and substrate.

4. Strict Quality Inspection: Tests include gloss, hardness, impact resistance, salt spray resistance, and color consistency to ensure reliable product performance.

Contact Us