Aerospace-Grade High-Hardness Aluminum Plate 7075 T6 T651 T7351

7075 Aluminum Alloy Overview

7075 aluminum alloy is one of the earliest and benchmark alloys developed in the 7000 series and remains among the most widely used high-strength aluminum alloys. The addition of chromium gives it excellent resistance to stress corrosion cracking (SCC).

Thanks to its ultra-high strength (around 560 MPa) and outstanding strength-to-weight ratio, 7075 is widely used in the aerospace industry and has earned the nickname “aerospace aluminum.”

Like 2024 alloy, 7075 plate is available in both bare and alclad forms. Alclad (clad) versions improve corrosion resistance. Common tempers include T6, T651, T73, and T76. Typical applications include alclad sheets for aircraft skins and plates up to 4 inches thick for aircraft structural frames.

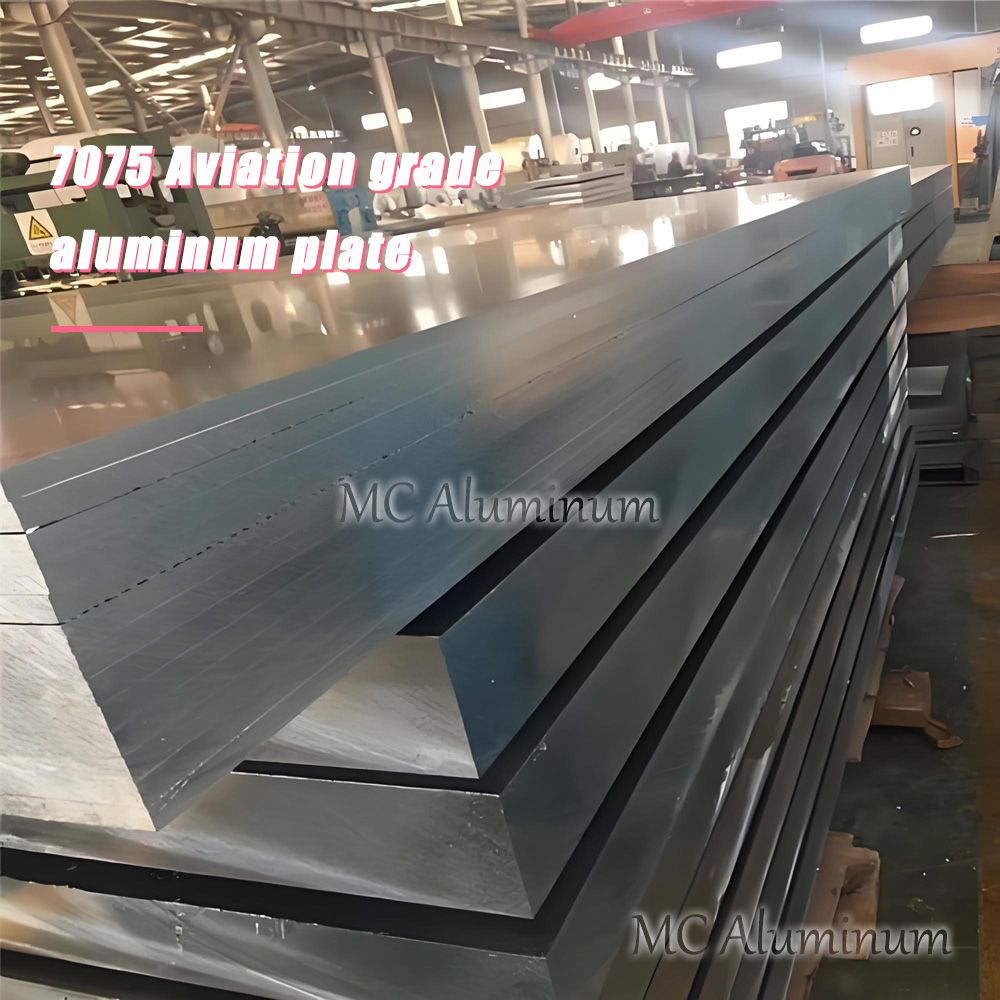

MC Aluminum provides a full range of 7075 aviation aluminum plates, including O, T6, T651, T73 and T7351 tempers, producing plates with a maximum width of up to 3800mm and a maximum thickness of 250mm, as well as up to 2650mm wide and 0.2mm thin to meet the thickness and width requirements of various orders.

7075 Aerospace Aluminum Plate Product Details

| Alloy | 7075 |

| Tempers | O, T6, T73, T76, T651, T7351, T7651 |

| Types | Bare plate, alclad plate, forged |

| 7075 Plate | Thickness 0.2 mm–8 mm, Width 900 mm–2650 mm |

| 7075 Plate | Thickness 8 mm–250 mm, Width 1000 mm–3800 mm |

| 7075 Alclad Plate | Thickness 0.2 mm–6 mm, Width 900 mm–2650 mm |

| 7075 Extra-Wide Plate | Thickness 8 mm–250 mm, Width 1000 mm–3800 mm |

| Length | Up to 20 m fixed, cut-to-length or customized |

| Coatings | Black/white film, blue film, transparent film (thickness: 50 μm, 80 μm) |

| Surface Finishes | Bright, polished, hairline, brushed, sandblasted, embossed, etched, etc. |

7075 Aluminum Plate Typical Mechanical Properties

| ALLOY | TEMPER | DIRECTION | THICKNESS (MM) | TENSILE STRENGTH RM (MPa) | YIELD STRENGTH RP0.2 (MPa) | ELONGATION A50 (%) |

| 7075 Thick Plate | T651 | LT | 6-260 | 570-590 | 495-515 | 10-13.5 |

| T7651 | LT | 6-102 | 550-560 | 480-490 | 10.5-12.5 | |

| T7351 | LT | 6-102 | 500-520 | 420-435 | 10-12.5 | |

| 7075 Thin Plate | T6 | 0.5-3.5 | 550-570 | 480-500 | 10-15 |

7075 Aluminum Plate Tempers Explained

(1) 7075-T6

7075-T6 is the most classic and widely used high-strength temper, produced by solution heat treatment followed by artificial aging.

Process: Solution heat treated + artificial aging.

Features: Very high tensile strength (typically 560–580 MPa), high hardness (HB150–180), excellent strength-to-weight ratio.

Advantages: Ideal for highly rigid, load-bearing structural parts such as wing spars, aircraft frames, and racing components.

Limitation: Relatively lower stress corrosion cracking (SCC) resistance—recommended for dry or controlled environments.

(2) 7075-T651

T651 is based on T6 but adds stress relieving by stretching to eliminate residual stresses, preventing deformation during subsequent machining.

Features: Maintains T6’s high strength (~560 MPa) while offering excellent dimensional stability.

Advantages: Reduces distortion during machining (milling, drilling), widely used in aerospace structures and precision mold plates.

Applications: Large fuselage structures, joints, brackets, pressure die bases.

(3) 7075-T73

T73 is a heat treatment temper developed specifically to improve resistance to stress corrosion cracking (SCC).

Process: Solution heat treated with double or long-duration low-temperature aging to modify precipitate morphology and distribution.

Features: Slightly lower strength than T6 (typically 520–540 MPa), but significantly improved SCC resistance.

Advantages: Extends service life and safety in high-humidity or salt-fog environments.

Applications: Carrier-based aircraft, coastal airport equipment, aerospace components operating in harsh environments.

(4) 7075-T7351

T7351 is the stress-relieved version of T73, designed for thick plates that require both corrosion resistance and high dimensional stability.

Process: T73 aging plus controlled stretching.

Features: Combines T73’s SCC resistance with T651’s low residual stress.

Advantages: Avoids warping or cracking in large cross-section plates.

Applications: Large aerospace frames, fuselage plates, carrier-based aircraft components in corrosive environments.

What Makes 7075 Aluminum Plate Special?

Originally developed for aircraft frameworks, 7075 plate offers an exceptional strength-to-weight ratio and is often used as a substitute for 2024 aerospace-grade aluminum.

Key Features:

1. Extremely high tensile and yield strength

2. Ultra-high hardness

3. Excellent mechanical properties

4. Good SCC resistance (especially in T7x tempers)

5. Outstanding strength-to-weight ratio

6. Good machinability

Typical Applications of 7075 Aircraft Aluminum Plate

Aircraft wing spars, fuselage frames, landing gear supports

Military drones, missile shells

Helicopter rotor hub links

Aerospace skins (Alclad sheets)

High-end molds, die bases

Lightweight racing/motorcycle chassis

Robotic structural joints

FAQ

Q1: How is the corrosion resistance of 7075 aluminum plate?

A1: 7075 aluminum plate has good atmospheric corrosion and exfoliation resistance. T7xx tempers (T73, T7351) offer significantly better SCC and exfoliation resistance than T6xx tempers. For applications needing extreme corrosion resistance, such as aircraft skins, 7075 Alclad plate is recommended.

Q2: Can you supply extra-thick 7075 aluminum plates?

A2: Yes, we can! Standard thickness ranges from 6 mm–200 mm and can be cut to length as needed. Our 7075-T6 rolled plate can reach 400 mm thick, 7075-T651 stretched thick plate up to 260 mm, and 7075-T652 forged blocks up to 500 mm.

Q3: Where is it used on aircraft?

A3: 7075 plates are typically used for wing spars, fuselage frames, and landing gear supports.

Q4: Do you support custom production?

A4: Absolutely! We offer custom options for temper, size, surface finish, and packaging. MC Aluminum delivers fast sampling, stable lead times, and export-ready solutions.

Q5: Do you accept export orders?

A5: Yes! We export to over 40 countries and regions worldwide, providing material certificates, test reports, and export packaging to seamlessly serve global markets.

Contact Us